28 Years Experience at Volume PCB Manufacturing

20 Years Experience at PCB Assembly Projects

One-Stop Turnkey EMS Service, OEM/ODM

Factory directly, No MOQ, No Third Party

Quality Guarantee, Timely delivery, Fast response, Reliable after-sales service

Full-service Turnkey PCB Assembly Solution

PCB manufacturing, Components sourcing and in-house assembly, Product Lifecycle Management

- Adopt advanced automation equipment ,provide strictly Quality Control

- E-test, AOI, X-ray, Function test for each board. Quality requirements meet ISO 9001 2015,TUV SUD certification.

- Lead Time & competitive Price

- Fast lead time and on-time delivery rate reaches 97%. Urgent delivery is available.

- Direct factory price,try our best to lower the cost with same quality and service

- OEM Service and Engineering support-Offer one-step OEM and OEM service from PCB manufacture, components sourcing, PCB Assembly, Function testing, Enclosure mold, finished products assembly,also powerful engineer design team with barrier-free English communication.

- Anti-static package and standard Carton Outside. Prevent damage to the circuit boards during transportation. And can also be customized according to requirement.

Quick-turn Prototyping

Fast-turn around 24 hours PCB prototype

- Quick prototype turnkey PCB Assembly within 7 days

- High end Manufacturer: Rigid, Flex, Rigid-Flex, HDI, Metal Core, 10-40 layers etc.

- On-Demand Fabrication

Strong Supply Chain Management

Consist of wide qualified distributor and huge selection in-stock.

- Components are ready to Ship or Assembly

- 100,000+ Parts In-stock components

- 2000m² Component Warehouse

- 800+ Qualified suppliers and vendors

- 50+ Experts Procurement Team

- 20+ sec Instant Result

- 7,000,000+ Parts Real-time Stock & Price

PCB Assembly

Fast turnaround of PCB fab, stencils and PCB assembly

- Choice of local or international contract manufacturers

- Leaded, lead-free, RoHS, through-hole, SMT capability

Final Assembly & Test

Conformal Coating, potting

- Plastic molding, sheet metal

- Painting, powder coating

- Cable assembly – Data, Power, RF & Optical

- Automated Production Test

Our PCBA capabilities are listed in the table below

1 | Min. Order Quantity | ≥1PC |

2 | Board Type | Rigid PCB, Flexible PCB,Rigid-Flex

PCB |

3 | Assembly Types | Surface mount (SMT), Through-hole

(DIP), Mixed technology (SMT & Thru-hole) |

4 | Board Size | 50mm*50mm~510mm*460mm |

5 | Quality Grade | IPC-A-610 |

6 | Min Package | 01005(0.4mm*0.2mm); Min. BGA Dia.

0.14mm; Min. BGA Pitch 0.2mm |

7 | Mounting Accuracy | ±0.035mm(±0.025mm) Cpk≥1.0

(3σ) |

8 | Surface Finish | Lead/Lead-free HASL, Immersion

gold,OPS etc. |

SMT Capacity | 3 Million~4 Million Soldering

Pad/day |

DIP Capacity | 100 Thousand Pins/day |

Lead time | 24 hours expedited service can be

offered. 3- 4 days normally for PCBA prototype orders. We will give you

accurate lead time when we quote for you. |

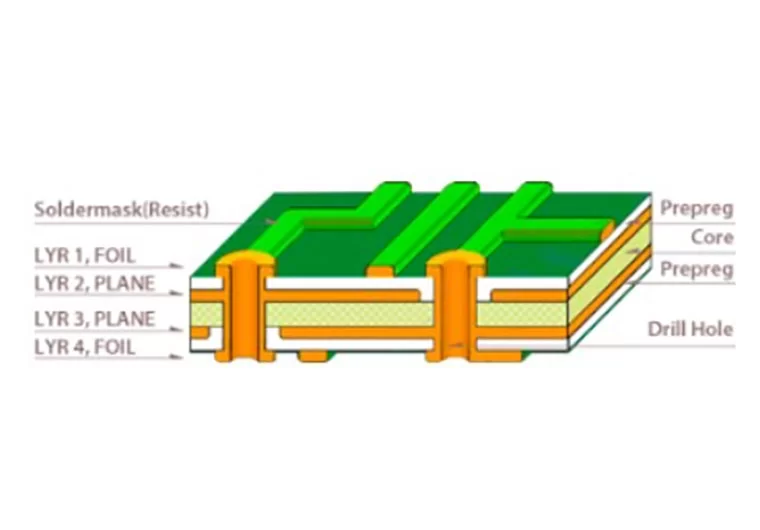

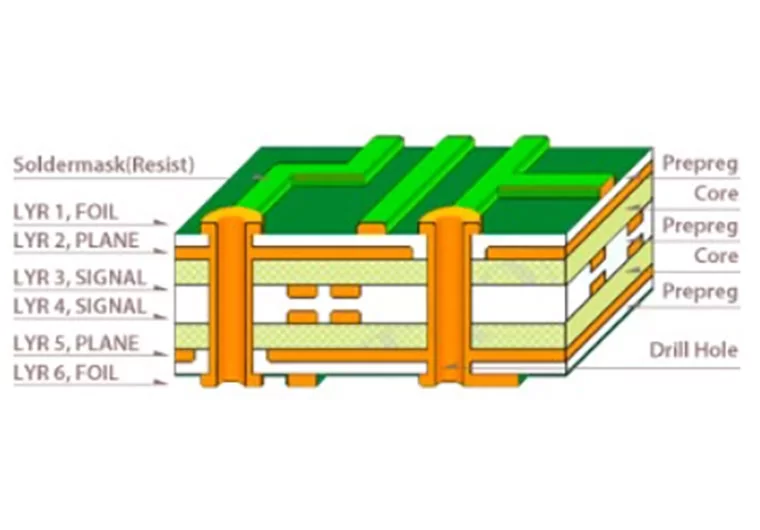

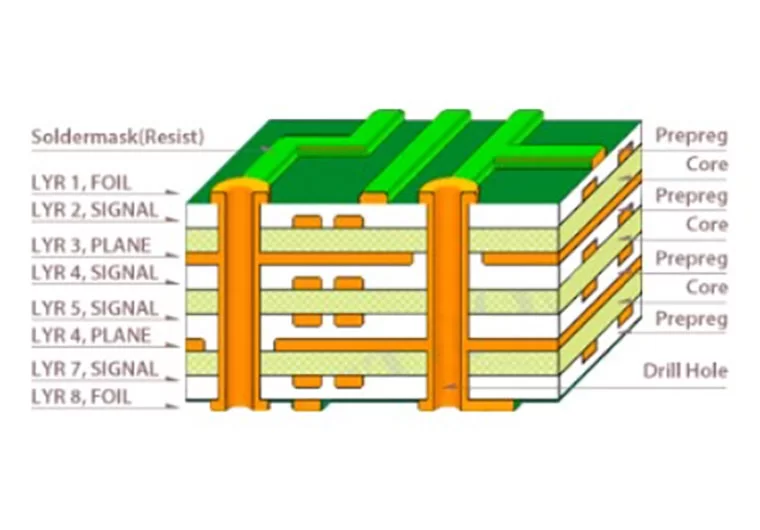

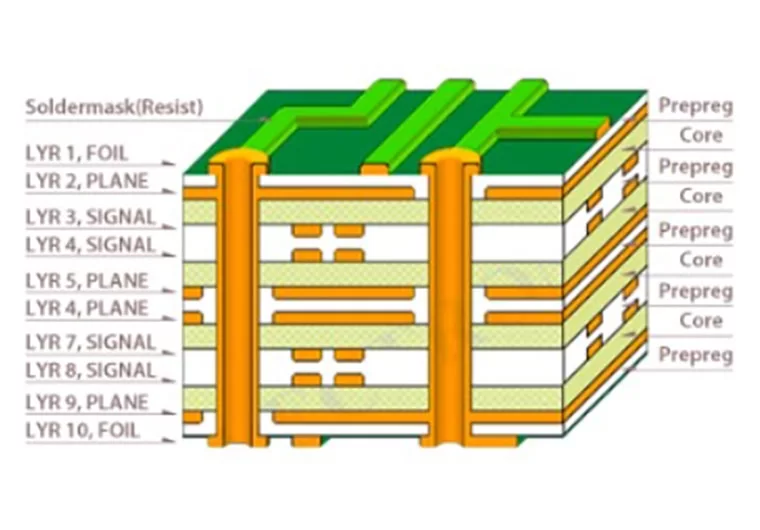

Multiple Layer PCB Stack-up

PCB Material

PCB laminate users hign quality Fr4,Rogers,and Aluminum material for PCB production.

4-Layer PCB with 2 Routing Layers,

a Ground Plane and a Power Plane

6 layer PCB has GTL, GBL,

and 4 inner layers. Every signal that

travels from 1 to 6 layers

8 layer PCB has GTL, GBL,

and 6 inner layers. Every signal

that travels from 1 to 8 layers

10 layerPCB hasGTL,GBL,

and 8 inner layers. Every signal

that travels from 1 to 10 layers

Quality Assurance

Quality and Policy :

Continually improve our quality, efficiency, service to satisfy the customer's requirement.

Certificate

Our factory is fully compliant with standard of GJB9001, ISO9001, ISO14001, ISO45001, ISO13485, IATF16949 quality system management .All the products are certificated with UL,REACH, ROHS and CQC.

Quality System

1. ISO-9001:2018 Quality System Standard

2. Quality Standard: IPC-610-D class 2,

- 3. Soldering Standard: J-STD-001 class 1,2,3

- 4. ESD Standard: ESD-MIL-STD-1686

- 5. Workshop management:7S

- 6. FAI-first article inspection

- 7. In process visual inspection

- 8. AOI inspection

- 9. Machine calibration and preventative maintenance

- 10. ERP material and process management ( ERP=enterprise resource planning computer system)

Quality standards

IPC-A-610D-G

RoHS management:

Product compliant: RoHS

RoHS prohibited substances list :

NO. Name The upper limit(ppm=mg/kg)

1 Pb 0.1%(1000ppm)

2 Hg 0.1%(1000ppm)

3 Cd 0.001%(100ppm)

4 Cr VI+ 0.1%(1000ppm)

5 PBB 0.1%(1000ppm)

6 PBDE 0.1%(1000ppm)

Testing and PCBA maintenance department

HUB Circuits provide custom test service according to client's requirements and products. Usually we offers PCBA Tech a full range of testing service. Including:

AOI(Automatic Optical Inspection)

Function Testing

- In Circuit Testing

- Testing Jig

- X-Ray for BGA Testing

- Printing Solder Paste Test

Each board is carefully examined by our dedicated inspection team using AOI and high magnification viewers.

Using our X-Ray machine, we test PCBs to component level and all wiring is fully inspected and tested. Flash

testing and earth bonding tests can also be undertaken where required

Fast Turn & Lead Time

Prototype: 3-5days

- Quick turn:2-5days

- Low volume: 5-10days

- Mass production: 2-3weeks

- Choose the best international express per your request.

On-time Shipping Guaranteed

99% on-time shipping by DHL

- 24 hour online customer service

- Shorted delivery by DHL to only 3-5 days

- 24 hours expedited services for PCB and PCBA fabrication

- Track your PCB and assembly order status online

Common packaging:

PCB: Vacuum packaging with carton box

PCBA:ESD packaging with carton box

Reasonable Price Guaranteed

Instant quote with no hidden cost $5 for 5-10pieces.

10*10cm PCB prototypes $30 OFF for SMT assembly components cost.