What is PCB Assembly?

PCB Assembly is the process of soldering the electronic components on a bare PCB board. Printed circuit assembly can be done manually or by machine. But PC board assembly by automatic equipment is used in the majority of situations because of its high efficiency and reliability. Generally speaking, there are two types of PCB board assembly: PTH assembly and SMT assembly.

PCB Assembly Capabilities | |

| QFP, SOP, PLCC, BGA |

SMT Jointing Capability | 1206, 0805, 0603, 0402, 0201,01005 |

Assembly Service | PCB manufacturing,components sourcing and in-house assembly, whole project management available |

Providing OEM service to all sorts of printed circuit board assembly | |

| Professional Surface-mounting and Through-hole soldering Technology |

Various sizes like 1206,0805,0603 components SMT technology | |

ICT(In Circuit Test), FCT(Functional Circuit Test) technology | |

PCBA Assembly With CE, 3C, Rohs, IATF16949 Approval | |

High Temperture reflow soldering technology for SMT | |

High Standard SMT& Solder Assembly Line | |

High density interconnected board placement technology capacity | |

Quote&Production Requirement | Gerber File or PCBA File for Bare PCBA Board Fabrication |

Gerber File, Bom (Bill of Material) for Assembly,PNP(Pick and Place file) and Components Position also needed in assembly | |

To reduce the quote time, please provide us the full part number for each components, Quantity per board also the quantity for orders. | |

Testing Guide & Function Testing method to ensure the quality to reach nearly 0% scrap rate | |

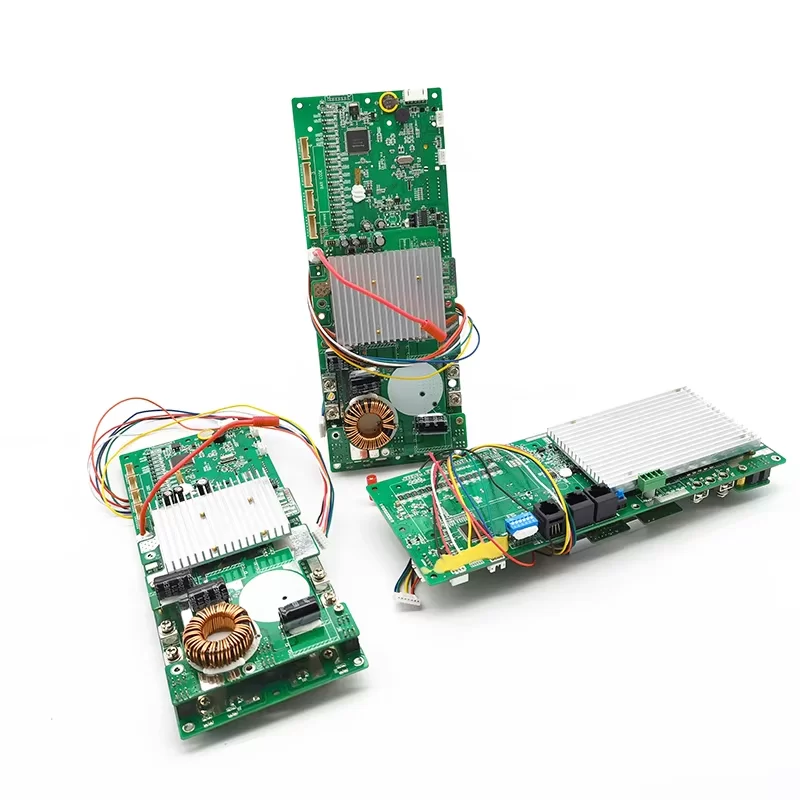

OEM/ODM/EMS Services | PCBA, PCBA Aassembly: SMT & PTH & BGA |

PCBA and enclosure design | |

Components sourcing and purchasing | |

Quick prototyping | |

Final assembly | |

Test: X-ray, AOI, In-Circuit Test (ICT), Functional Test (FCT), ATE, etc | |

Production equipment: Guarantee for your production | Automatic Printing Machine –SMT Machine – Reflow Soldering Oven – Wave Soldering Oven – Automatic Welding Machine – Automatic Plug-in Machine – PCB Splitting Machine – PCBA Board Washing Machine – Conformal Coating Machine -Potting Machine |

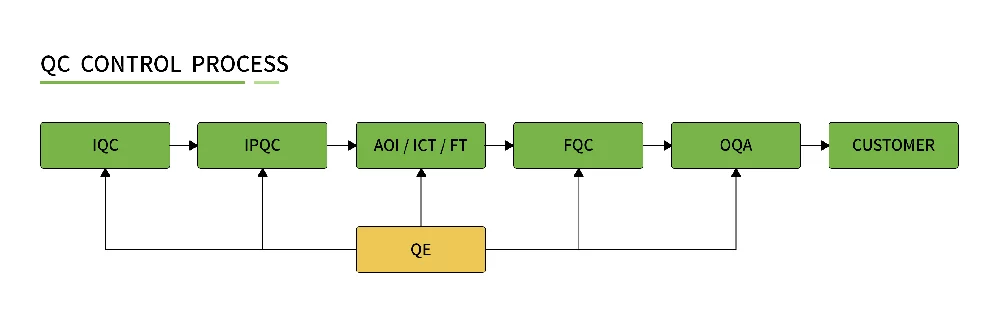

Testing equipment: quality control for your products | X-ray Detector for Components–Automatic Stencil Test Machine—Online AOI Detector–X-Ray Detector–Automatic 1st Sample Tester — Online SPI — Solder Paste Detector – High & low Temperature Tester – ATE Detector |

Main Types of Printed Circuit Board Assembly

Through Hole Technology

The older method of PC board assembly involves the insertion of the leads in pre-plated holes on the PCB to be able to interconnect the parallel layers. This method is referred to as Through Hole Technology or THT. The components are inserted using an automatic insertion machine where a program is first uploaded to the machine controller. The PCB then goes through a wave soldering process wherein the PCB is conveyed to a solder wave and immersed for a few seconds.

There are also two types of components that can be attached to the PCB using through-hole technology. One is axial lead, the other is radial lead. Axial lead is a component with axial leads that has its leads protruding along the axis of the component. Radial lead is a component with radical leads that run perpendicular to the major axis of the electronic component.

After the automatic insertion and wave soldering process, the printed circuit boards undergo PCB testing to determine electrical openings and shorts. This is done by checking the node-to-node resistance when the electric current is applied.

The Advantages of Through Hole Technology

High Mechanical Strength:Using through-hole technology, the component leads traverse through the layers of the printed circuit board, being secured firmly and giving the overall structure high mechanical strength. THT is therefore most applicable for devices that are frequently subjected to mechanical stress.

Easier to Adjust and Repair: Since through-hole technology components are inserted into the printed circuit boards and wave soldered on the other end of the leads, it is easier to disassemble, adjust and even replace. This is why it is also more convenient to use THT for testing and prototyping activities.

High Power Capabilities: Through hole components are generally larger than surface mount devices and with higher power handling capacity. THT is widely utilized in transistors, transformers and voltage regulators requiring high currents.

Excellent Durability: High mechanical strength is its outstanding durability even when subjected to harsh environmental conditions. With their sturdy connections and large size, they are more resilient to vibration and thermal stresses thereby prolonging the product’s life.

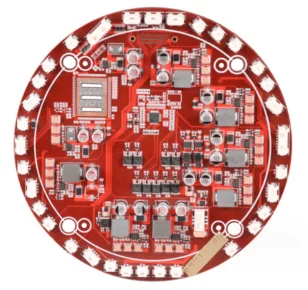

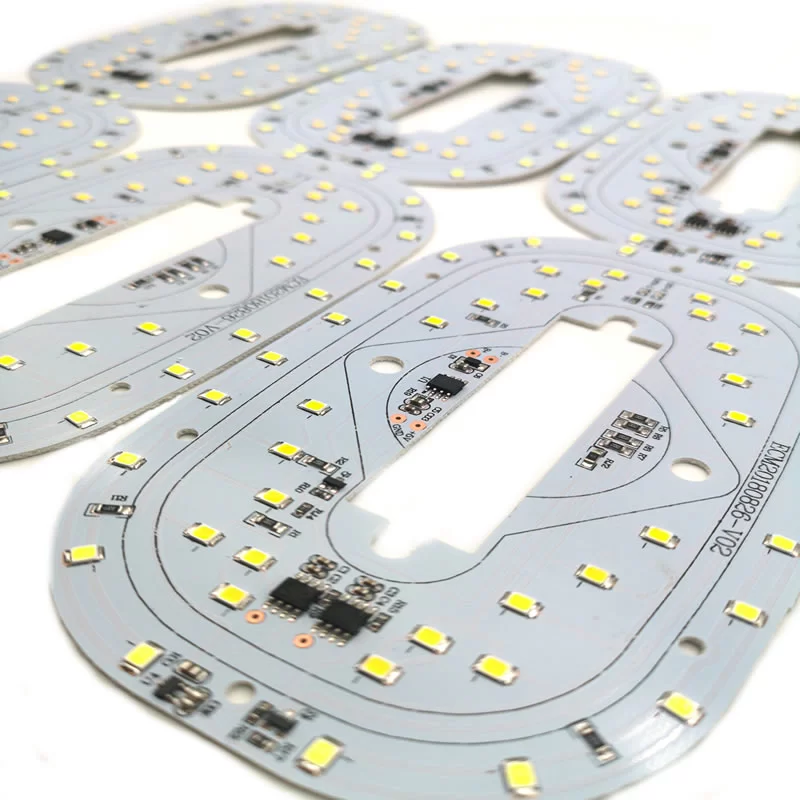

Surface Mount Technology

The latest PCB assembling method makes use of solder paste technology to directly mount the components into the board pads. In this manner, narrower spacing between components is allowed. Miniaturization of electronic devices paved the way for this type of printed circuit board assembly as smaller pads, smaller packages and smaller circuitry can be utilized. Even if surface mount technology corresponds to significant benefits, some applications still require through-hole technology or mixed assembly techniques. This includes power supplies wherein transformers and capacitors would require mechanical strength from THT.

The Advantages of Surface Mount Technology

Surface Mount Technology offers numerous advantages which enable the production of smaller devices with higher functionality. More PCB circuit board assembly manufacturers are willing to use SMT than THT. Explained below are the detailed benefits that can be gained with SMT processes.

Smaller and Lighter Packages: With SMT, components can be directly mounted more closely spaced with thinner leads. Holes do not need to be drilled unlike with the THT process. This results in smaller and lighter packages.

Higher Pin or Lead Counts: Surface Mount Technology allows higher I/O counts with more pins and leads to be sold onto the PCB surface.

More Functionality: Since SMT can be used for higher pin or lead counts, interconnection per area is more maximised.

High Frequency Operations: With a higher packaging density design, SMT gives room for shorter connection paths leading to higher frequency options.

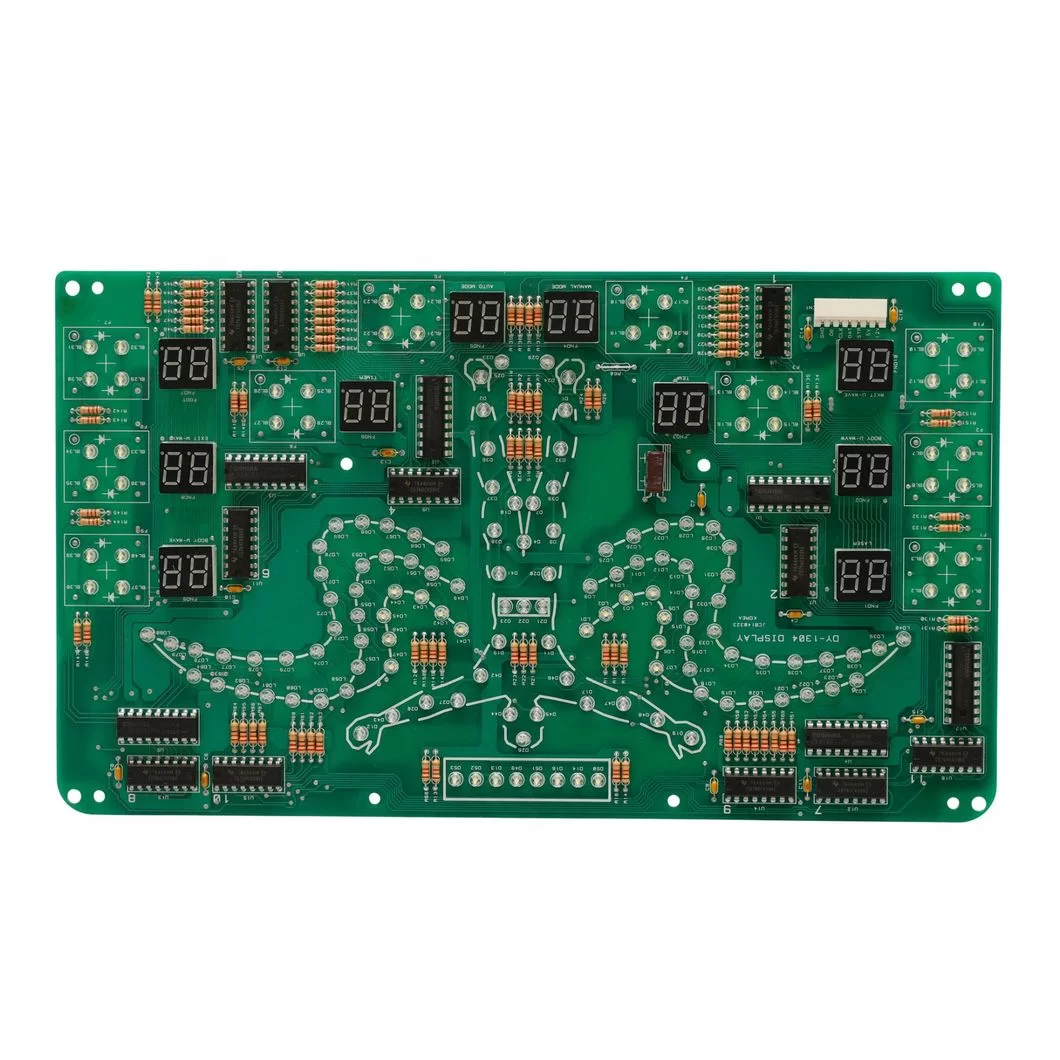

Auto Electronic PCB Assembly

Medical electronics PCB Assembly

Industrial Control PCB Assembly

Consumer Electronics PCB Assembly

Motor Power PCB Assembly

loT PCB Assembly