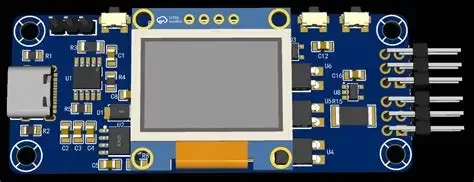

What is PCB Design?

PCB design is the process of designing a printed circuit board that has conductive layers around a non-conductive material and components laid over it.It’s a collaborative process of many factors. It includes the delicate integration of electronics, mechanics, software, manufacturing, testing, and economics. It requires a perfect compromise in each domain to build a perfect printed circuit board PCB design. The capability of manufacturers and the ever-increasing technological advancement have made complex designs very common. Smartphones, wireless earphones, laptops, TVs, etc. are prime examples of common and complex devices designed by PCB design company.

Our PCB Design Process

Our PCB design process is tailored for precision and client satisfaction through structured steps and continuous client involvement.

Design and Verification

Start and Footprint Verification: We initiate the PCB design by aligning with your requirements, followed by verifying and creating component footprints.

Component Placement and Routing: Critical components are placed and routed first for optimal functionality, followed by general components, ensuring the design adheres to performance standards.

- Reviews and ApprovalsRegular Reviews: Each critical phase—component placement, routing, and post-design rule checks—is followed by a detailed review and requires your approval. This ensures the PCB design matches your specifications precisely.Adaptive Changes: Adjustments are made based on your feedback, continually refining the PCB design.

Finalization

Final Review and Deliverables: The PCB design undergoes a final verification before we prepare all necessary documentation for production. This stage marks the completion of the design process, readying it for manufacturing with your full approval.

Our approach integrates your feedback at every step, ensuring the final PCB design meets your exact needs and quality expectations.

Factors Governing a PCB Board Design

Electrical Performances

The foremost and the biggest contributor to the quality of a printed circuit board PCB design is its electrical performance. Electrical performance is accounted for by factors like:

Signal Integrity: Signal integrity is the measure of the quality of the signal traveling along the path provided for it on the PCB. A high signal integrity ensures that the signals on the PCB do not lose power, and are not introduced to any more noise while on the PCB.

Power Distribution: Power distribution ensures there is enough power for all the components used to function effectively. Poor power distribution results in the malfunction of components and the generation of heat on the PCB board.

- Choice of Materials: The use of appropriate dielectric material and the appropriate amount of copper affects the electrical capabilities of a PCB.

Noisy signals, heating of PCB during normal operations, voltage fluctuations, etc. are caused due to poor electrical design.

Mechanical Requirements

Mechanical considerations are one of the key factors of a printed circuit board PCB design. The factors affecting the mechanical properties of the PCBs are:

Size: The size of the PCB is its length and breadth. Longer PCBs are prone to bending over applying mechanical stress on the edges.

- Thickness: The thickness of the PCB is an important factor for mechanical integrity. A thin PCB is prone to breaking and bending. A thick PCB increases the weight of the PCB but also the mechanical integrity.

- Flexibility: The flexibility of the PCB depends on the material of the PCB and its thickness. Materials like polyimide are bendable to some extent and hence are used in PCBs that are required to bend. It must be noted that rigid PCBs must not bend until required by design.

Other mechanical properties include the material of cores, the material of dielectric, the type of vias, the surface finish, etc.

Economics Considerations

A very important part of custom PCB design is maintaining the economics of the PCB. The economics of the PCBs are accounted for by:

Material and Features Used: The material and the features used for fabricating the PCB directly affect the cost of the PCB. As a general trend, the more advanced the feature or material used on PCB will result in more expensive PCB.

- The Complexity of the Design: Irregular shapes and stackups of PCB generally cost more than simple shapes like rectangles and circles.

- The Supply Chain of the PCB Design Company: Generally factor in the last stages of printed circuit board PCB design, the PCB design company’s supply chain is a major factor in the cost of the PCB. Factors such as lead time, the scale of the quantity, and the geography of the vendor all are included in the supply chain.

Tools Needed in Printed Circuit Board PCB Design

PCB Design Software

Printed circuit board PCB design software or EDA (electronic design automation) tools are required for schematic design, PCB layout, as a 3D visualizer( a 3D visualizer is not compulsory but it is better to have it) and for Gerber file generation. Generally, most of the EDA tools have all of them in one software. Some of the examples are OrCAD, Altium, and KiCAD.

Simulation and Analysis Tools

SPICE (Simulation Program with Integrated Circuit Emphasis) and SI ( Signal integrity) tools are used for simulating circuit behavior, electrical characteristics, and performance parameters. They are not strictly necessary for simpler designs, but it is recommended to be used. Some of the examples of SPICE tools are LTSPICE and PSPICE. Some of the examples of SI tools are AnSys and Hyperlynx.

Prototyping and Testing Tools

A very important part of PCB design is board bring-up and testing. It is required for section-wise testing of the board.