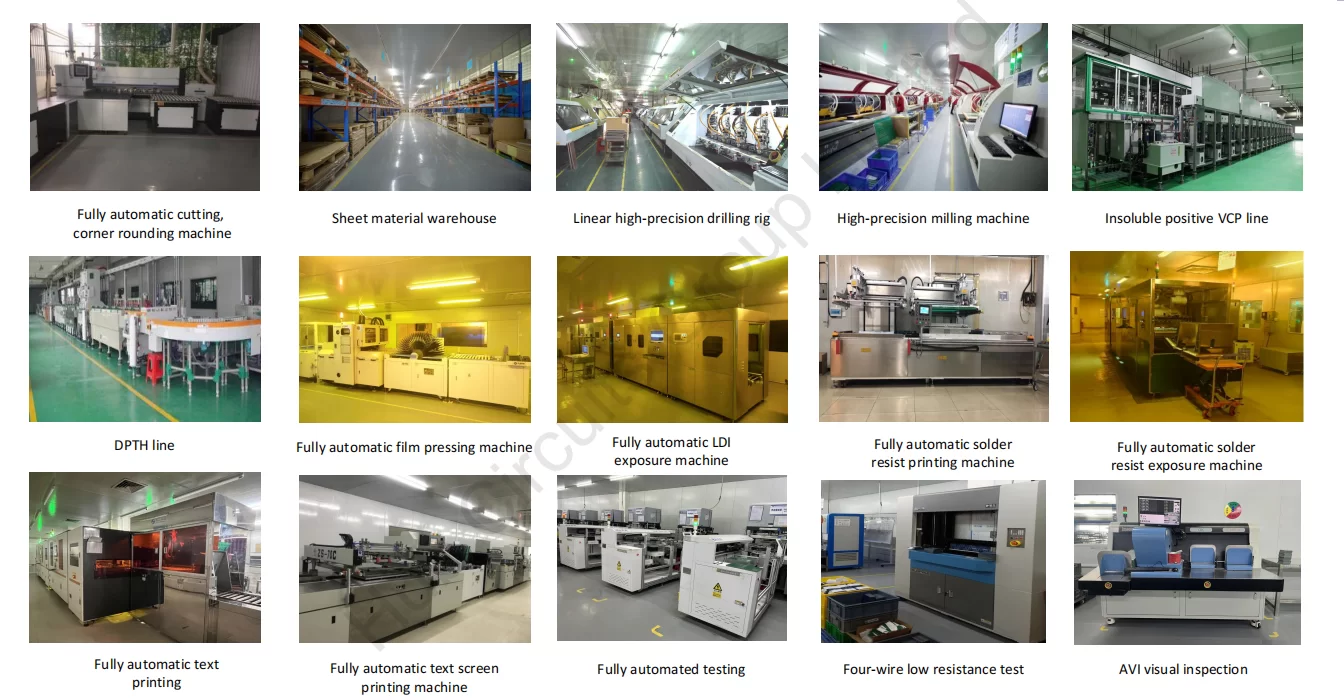

General PCB Manufacturing Process Flow:

1: PCB Design and File Preparation

2: Photoplotting and Film Production

3: Inner Layer Imaging and Etching

4: Layer Alignment and Lamination

5: Drilling

6: Chemical Copper Deposition

7: Outer Layer Imaging and Electroplating

8: Outer Layer Etching

9: Solder Mask Application

10: Silkscreen Printing

11: Surface Finishing

12: Electrical Testing

13: Routing and V-Scoring

14: Final Inspection, Packaging, and Shipping

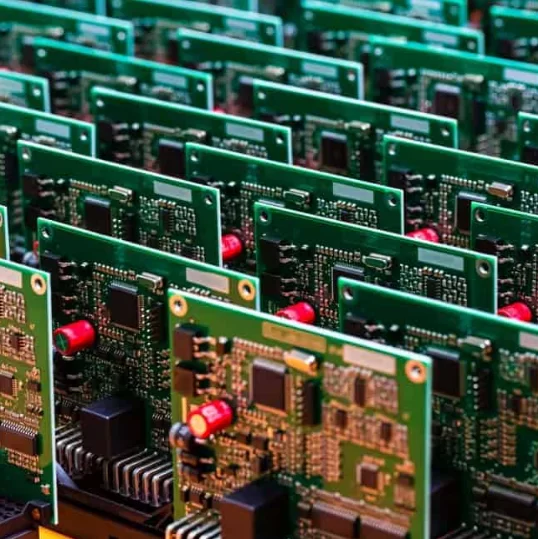

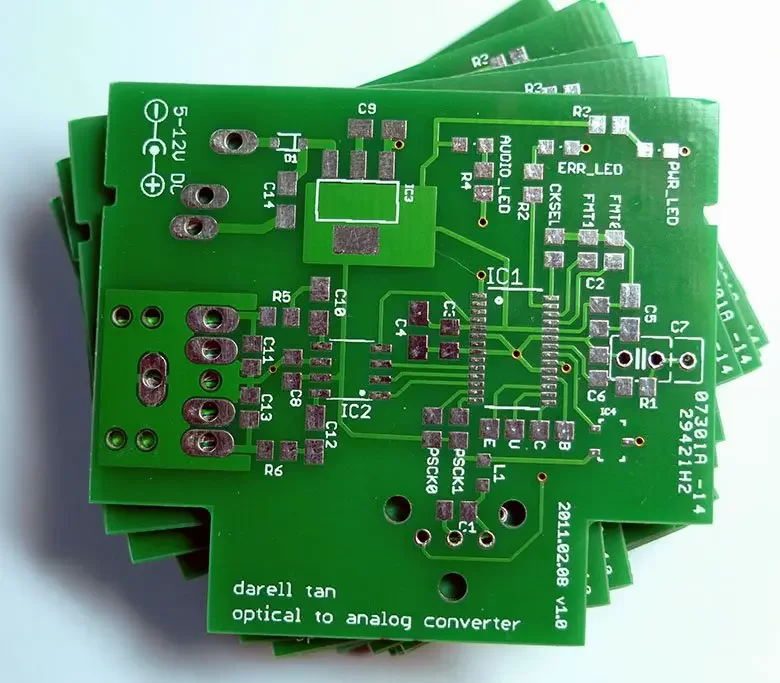

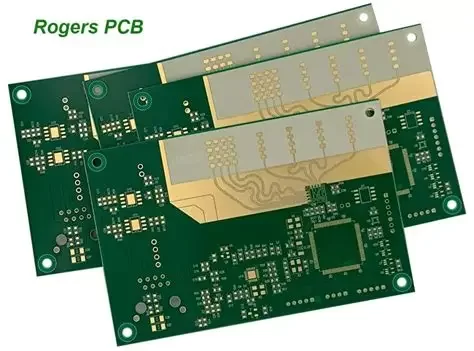

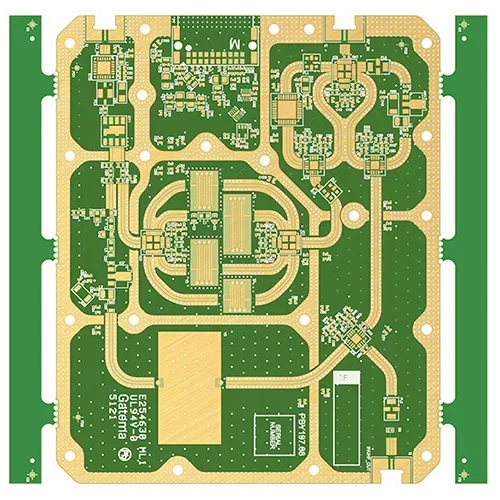

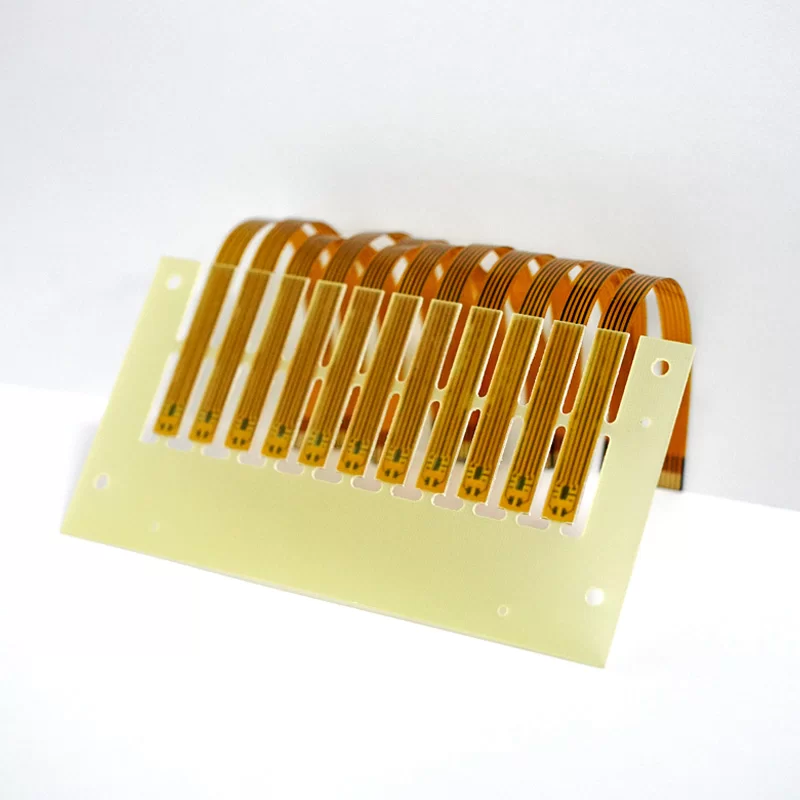

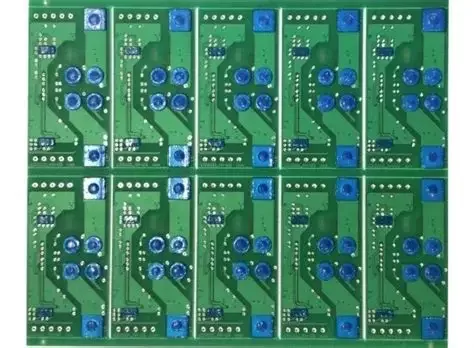

The PCB we made:

E-Test File Requirements

For accurate and complete testing, we recommend customers provide a netlist file (IPC-356 format) along with Gerber data. A netlist derived directly from the design source ensures high fidelity and accurate fault detection. If a netlist is not provided, we will generate one from the Gerber files for continuity testing.

Providing the design netlist:

Increases test coverage accuracy

Avoids discrepancies from CAM changes

Ensures compliance with high-reliability standards

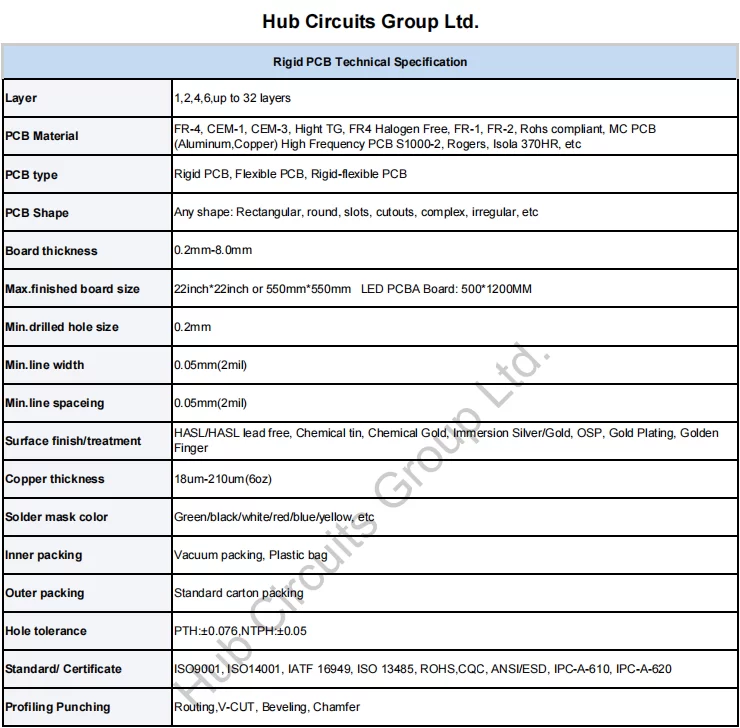

FR-4 PCB

Rogers PCB

Ceramic PCB

High frequency PCB

IC Substrate PCB

Rigid Flex PCB

HDI Portable Electron PCB

Blue Peelable PCB

Our PCB material