HUB Circuits Group has offered high-quality PCBs and the best PCB assembly service all over the world since 2002.

We have been specializing in quick-turn PCB prototyping and turnkey PCB assembly services and are one of China's leading companies in the industry.

As electronics engineers' best partners, we remain committed to providing unparalleled service.

All of your orders will be reviewed by HUB Circuits engineers. Our principle is to use our profession to ensure that you get exactly what you expect.

PCB Manufacturing Service

PCB layout, PCB design according to your idea

PCB copy/reverse engineering

- Digital Circuit Design/ Analog Circuit Design/ lRF Design /Embedded Software Design

- Firmware and Microcode Programming Windows Application (GUI) Programming/Windows Device Driver (WDM) Programming

- Embedded User Interface Design / System Hardware Design…

PCB Assembly Service

Electronic components material purchasing

Bare PCB fabrication

- PCB Assembly Service. (SMT, BGA, DIP)

- FULL Test: AOI, In-Circuit Test (ICT), Functioal Test (FCT)

- Cable, Wire-harness assembly,sheet metal,Electrical cabinet Assembly service

- Conformal coating service

- Prototyping and mass production…

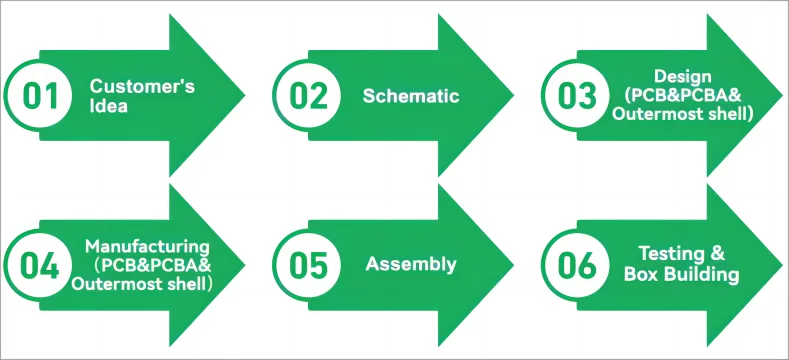

As a comprehensive electronics compan, HUB Circuits Group offers a wide range of services to support customers in bringing their ideas to life and transforming them into fully functional products. Our services encompass the entire product development process, providing a convenient one-stop solution for our clients. Here is a breakdown of our services:

1. Idea Design: Our team of experienced designers and engineers works closely with clients to understand their concepts and requirements. We assist in conceptualizing and refining ideas, ensuring they are viable and optimized for the intended purpose.

2. PCB Design: We offer professional PCB (Printed Circuit Board) design services. Our skilled engineers create customized circuit board layouts, taking into account the specific needs of the product and its functionality.

3. Structure Design: In addition to PCB design, we also provide structure design services. This involves designing the physical enclosure or housing for the product, ensuring it is aesthetically pleasing, functional, and meets the necessary specifications.

4. PCB Manufacturing: With our in-house PCB manufacturing capabilities, we can efficiently produce high-quality circuit boards. We utilize advanced manufacturing processes and technologies to ensure the reliability and performance of the PCBs.

5. PCB Assembly: We offer comprehensive PCB assembly services, which involve populating the circuit boards with electronic components. Our skilled technicians and modern assembly facilities ensure accurate and efficient assembly processes.

6. E-Test Fixture Manufacturing: We specialize in the manufacturing of E-Test fixtures, which are used to test the functionality and performance of assembled PCBs. Our fixtures are designed and manufactured to meet specific testing requirements.

7. Box-Building: Our in-house box-building capabilities enable us to provide complete product assembly services. We integrate the PCBs, mechanical components, and other necessary parts into the final product, ensuring a seamless and efficient production process.

Our goal is to provide a comprehensive range of services, from idea conception to the final product, ensuring that our clients' electronics requirements are met efficiently and effectively. With our expertise and capabilities, we aim to be a trusted partner in bringing innovative electronic products to market.

PCB capacity

Items | PCB capacity |

Product name | SMT circuit board manufacturer custom electronic assembly pcb pcba |

Material | FR-4; High TG FR-4; Aluminum; CEM-1; CEM-3; Rogers, etc |

PCB type | Rigid, flexible, rigid-flexible |

Layer NO. | 1, 2, 4, 6, up to 24 layer |

Shape | Rectangular, round, slots, cutouts, complex, irregular |

Max PCB dimensions | 1200mm*600mm |

Board Thickness | 0.2mm-4mm |

Thickness Tolerance | ±10% |

Min Hole Size | 0.1mm (4 mil) |

Copper Thickness | 0.5 OZ-3OZ (18 um-385 um) |

Copper Plating hole | 18um-30um |

Min Trace Width | 0.075mm (3mil) |

Min Space Width | 0.1mm (4 mil) |

Surface finish | HASL, LF HASL, Imm Gold, Imm Silver, OSP etc |

Solder mask | Green, red, white, yellow, blue, black, orange, purple |

PCBA capacity

Items | PCBA capacity |

Product name | SMT circuit board manufacturer custom electronic assembly pcb pcba |

Assembly details | SMT and Thru-hole, ISO SMT and DIP lines |

Testing on products | Testing jig/mold , X-ray Inspection, AOI Test, Functional test |

Quantity | Min quantity : 1pcs. Prototype, small order, mass order, all OK |

Files needed | PCB : Gerber files(CAM, PCB, PCBDOC) |

Components : Bill of Materials(BOM list) | |

Assembly : Pick-N-Place file | |

PCB Panel Size | Min size : 0.25*0.25 inches(6*6mm) |

Max size : 1200*600mm | |

Components details | Passive Down to 0201 size |

BGA and VFBGA | |

Leadless Chip Carriers/CSP | |

Double-sided SMT Assembly | |

Fine BGA Pitch to 0.2mm(8mil) | |

BGA Repair and Reball | |

Part Removal and Replacement | |

Components | Cut Tape, Tube, Reels, Loose Parts |

PCB+ assembly process | Drilling—–Exposure—–Plating—–Etaching & Stripping—–Punching—–Electrical Testing—–SMT—–Wave Soldering—–Assembling—–ICT—–Function Testing—–Temperature & Humidity |

Requirement for PCB,PCBA quotation:

1. BOM with reference designators: component description, manufacturer’s name and part number.

- 2. PCB Gerber files.

- 3. PCB assembly drawing.

- 4. Test procedures.

- 5. Any mechanical restrictions such as assembly height requirements

PCB board manufacture and PCBA service:

1. PCB board made, circuit board parts provided

- 2. Electronic testing circuit board or PCBA

- 3. Fast delivery, anti-static package

- 4. RoHS Directive-compliant, lead-free

- 5.One stop service from PCB design, PCB layout, PCB manufacture, components purchasing, PCB assembly, test, packing and PCB delivery

- 6. Electronic manufacturing service

- 7.Wire harnessing and finally enclosure assembly

FAQ:

1. Are you a manufacturer, or a trading company?

We are a professional high density PCB manufacturer since 2001, we have PCB factory in Guandong. Welcome to our factory for on-site communication and instruction.

2. How do you ensure the quality?

Our PCBs are 100% tested before shipment, including flying probe and AOI (default) / fixture test.

3. What are the main applications of your PCB/PCBA?

Our PCB are widely used in mobile terminal equipment, automotive electronics, network communication equipment, household appliances, office equipment, new energy equipment, industrial control and security, medical electronics, artificial intelligence and other fields.

4. How do you keep our product information and file secret ?

We respect customers' copyright and will never manufacture PCB for someone else with your files unless we receive written permission from you, nor will we share these files with any 3rd parties. We promise to keep customers information in high confidential level.

5. What is the leadtime?

3-6days for sample orders while 7 -12 days for mass production orders.

6. What is your minimum order quantity (MOQ)?

NO MOQ requirement, we can provide one stop PCB Solution (PCB+PCBA+ components) service to our customers.