PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

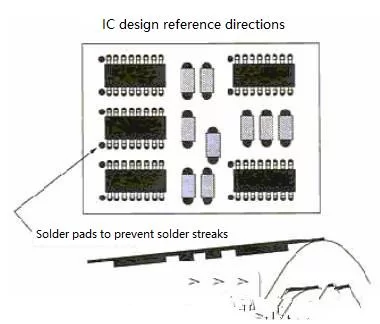

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.

PCB circuit board impedance refers to the parameters of resistance and reactance, which hinders AC power.

With the increasing market competition of communication and electronic products, the life cycle of products is shortening.

Nowadays, circuit board manufacturers are flooding the market with various prices and quality issues that we are completely unaware of.

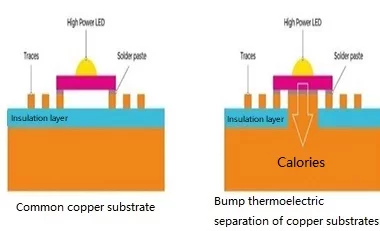

The copper substrate to do thermoelectric separation refers to a production process of copper substrate is a thermoelectric separation process, its substrate circuit part and thermal layer part in different line layers, the thermal layer part directly contact with the lamp bead heat dissipation part, to achieve the best heat dissipation thermal conductivity (zero thermal resistance).

If the PCB board is sealed and not unpacked, it can be used directly on the production line within 2 months of the manufacturing date.

The flying probe tester uses 4, 6, or 8 probes to perform high-voltage insulation and low-resistance continuity tests (open and short circuits of test lines) on PCB circuit boards without the need for test fixtures.

Hard gold plating, full plate gold plating, gold finger, nickel palladium gold OSP: Lower cost, good weldability, harsh storage conditions, short time, environmental protection process, good welding, smooth.

Electronic components can be seen everywhere in our life, and with the development of science and technology, the variety of electronic components has become more and more, but also began to be high-frequency, miniaturization of the direction of development.

Specification for Design of PCB Pad -- Pad Size (Three)

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.