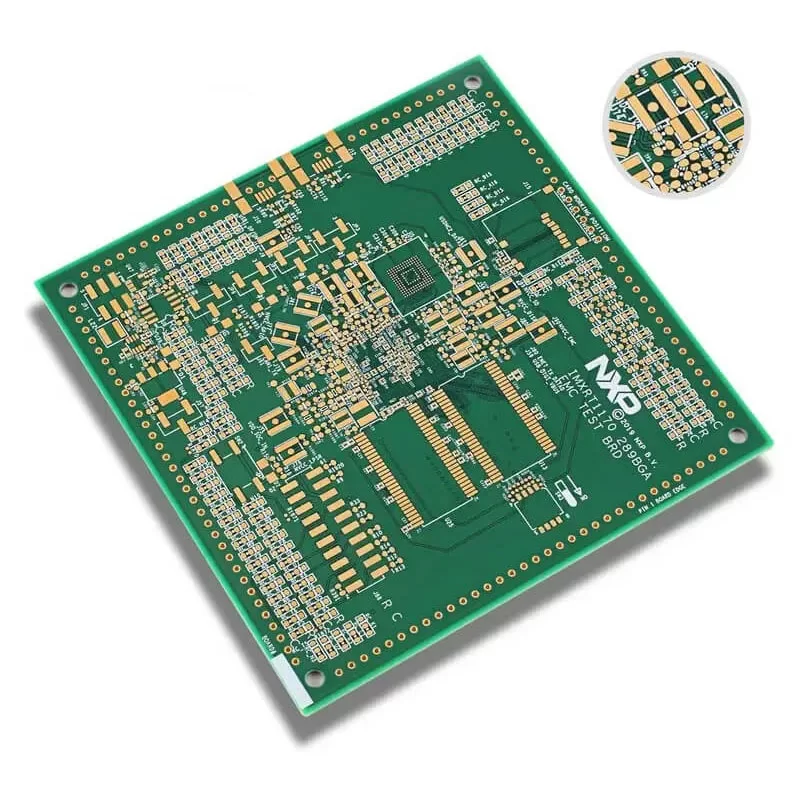

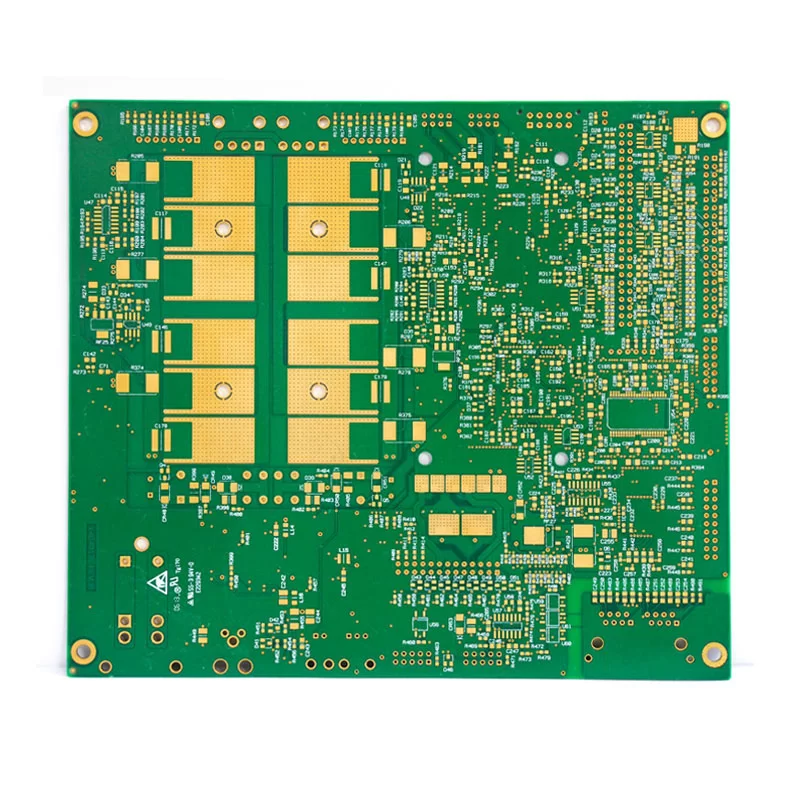

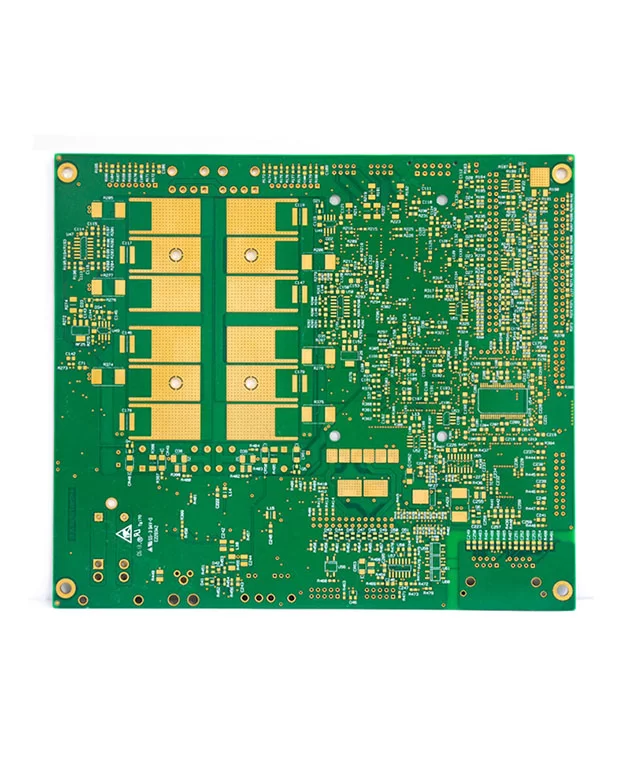

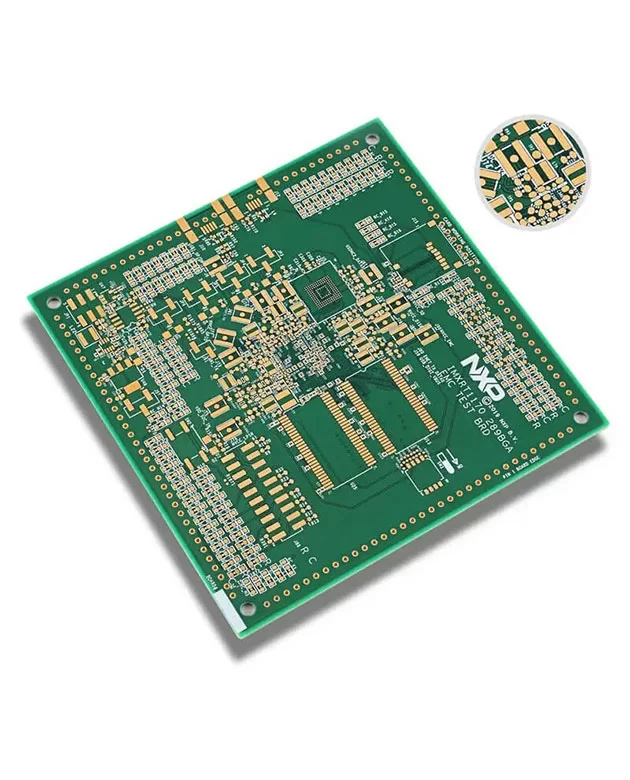

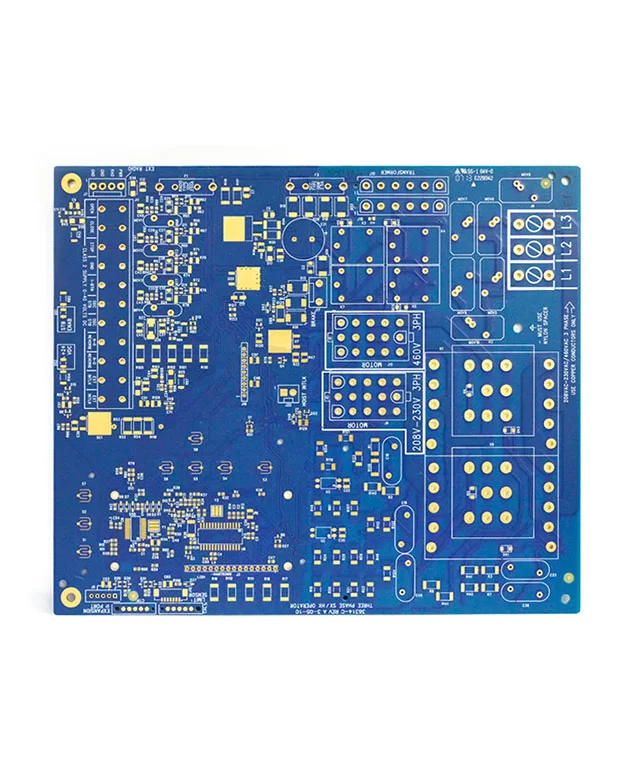

High-Quality Rigid PCBs

1.Higher Functionality: Rigid PCB boards allow multiple-layer construction and connection density, it has higher functionality and flexibility in board design.

2.Manufacturing Efficiency: The manufacturing processes of Rigid printed circuit boards are very efficient, automated, and standardized, it's being the earliest technology in printed circuit board, and already mature and developed.

3.High Reliability: Rigid PCB Circuit Boards are resistant to deformation due to their structural rigidity and durability. Due to their high reliability, most applications are reliant on the use of rigid printed circuit boards.

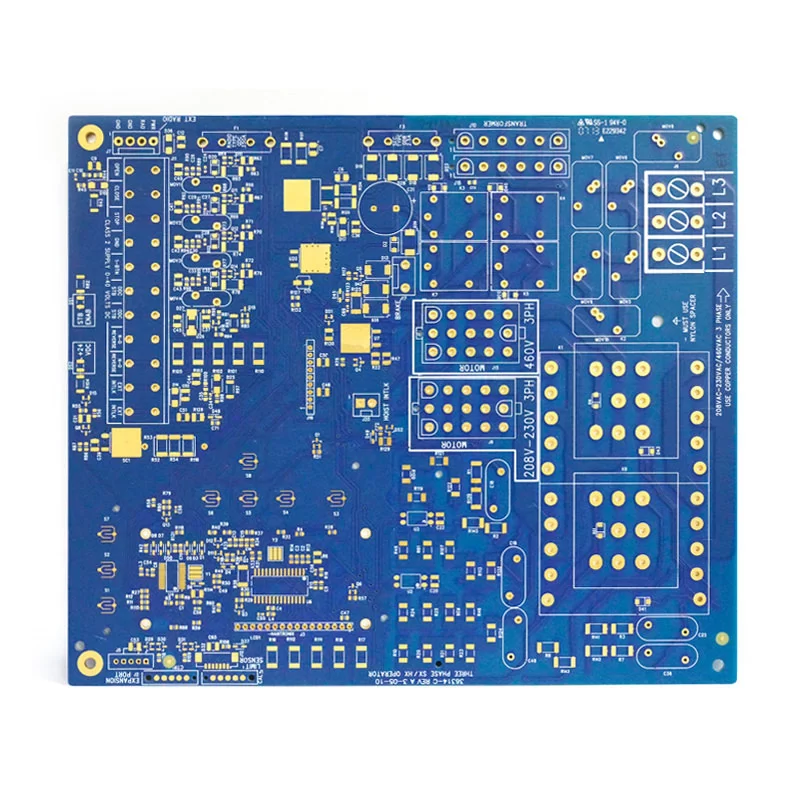

Application

Encompassing consumer, automotive, military, medical quipment, Mobile Phones, computer Motherboards, storage devices, Communication Technologies, Satellite, Radio, Antennas, Vehicles’Infotainment System, Industrial Electronics like Control Systems and Instrumentations etc.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.