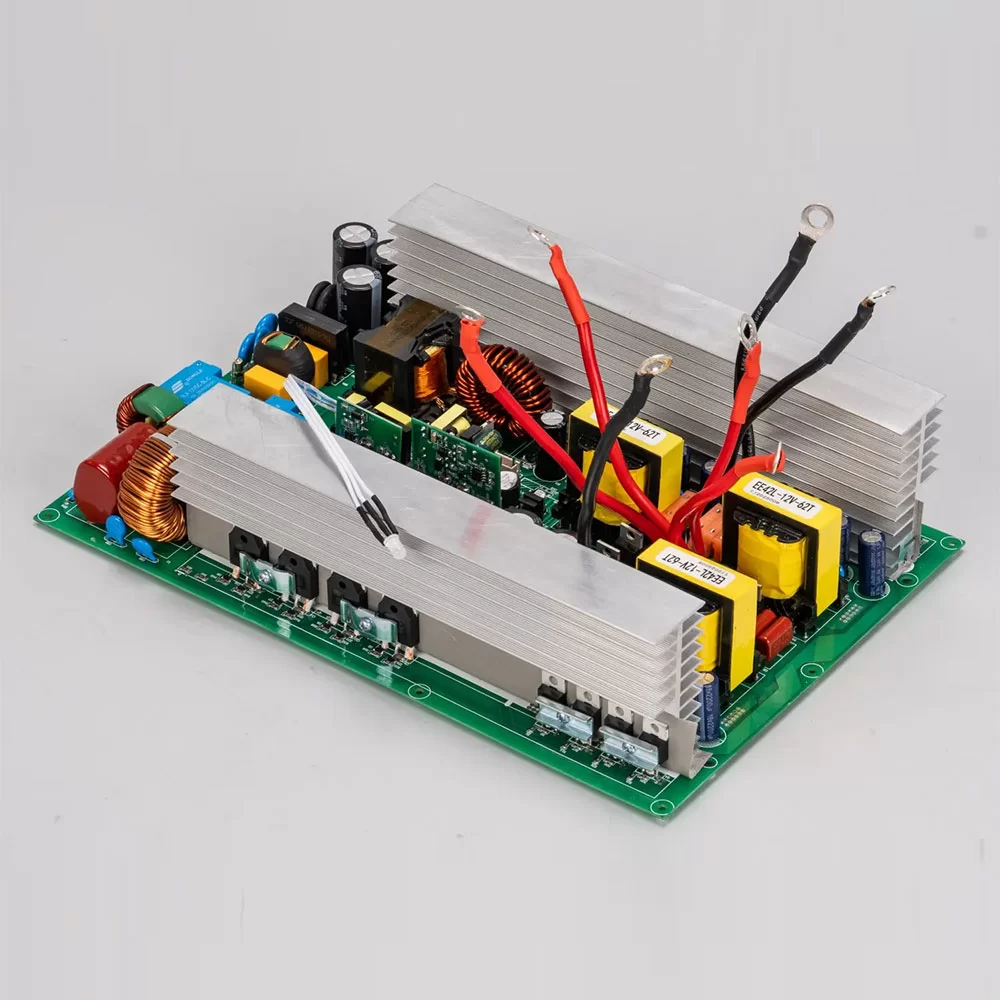

Solar Controller PCB Assembly

Why solar PCB assembly is important

Solar PCBs are the backbone of solar energy systems, controlling everything from power conversion to energy storage. Whether you're designing a small solar-powered device or a large-scale solar farm controller, the quality of your PCB assembly directly impacts efficiency, durability, and performance. Solar PCBs must withstand harsh environmental conditions like extreme temperatures, humidity, and UV exposure, making precision in assembly techniques critical.

Challenges in Solar Controller PCB Assembly

Assembling PCBs for solar applications comes with unique challenges due to the need for durability and efficiency. Here are common issues and solutions:

Thermal Stress: Solar Controller PCBs face wide temperature swings. Use components rated for extended temperature ranges and apply conformal coatings to protect against thermal expansion mismatches.

Moisture and Corrosion: Outdoor solar systems are exposed to humidity. Opt for no-clean flux and apply protective coatings with dielectric strengths of 50kV/mm or higher.

- Power Efficiency: Inefficient soldering can lead to resistance in joints, reducing power output. Ensure precise solder paste application and reflow profiles to achieve joint resistance below 0.1 milliohms.

The role of the Solar Controller PCB Assembly

The Solar Controller PCB Assembly excels in efficiently managing solar power by regulating the charging process. It intelligently monitors the solar panel output and battery status, ensuring that the battery receives the right amount of charge without overcharging or damaging it. This efficient power management enhances the overall performance of the solar power system, maximizing energy utilization and extending battery life.

Smart Protection Features:

The Solar Controller PCB Assembly offers comprehensive protection features to safeguard the solar power system components. It includes overcharge protection, short circuit protection, reverse polarity protection, and over-temperature protection. These built-in safety measures prevent damage to the batteries, solar panels, and other connected devices, ensuring reliable operation and system longevity.

Compact and Durable Design:

The Solar Controller PCB Assembly is designed with compactness and durability in mind. Its small form factor enables easy installation and integration into various solar power systems. The high-quality components and robust PCB assembly ensure reliability and long-term performance, even in harsh environmental conditions.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.