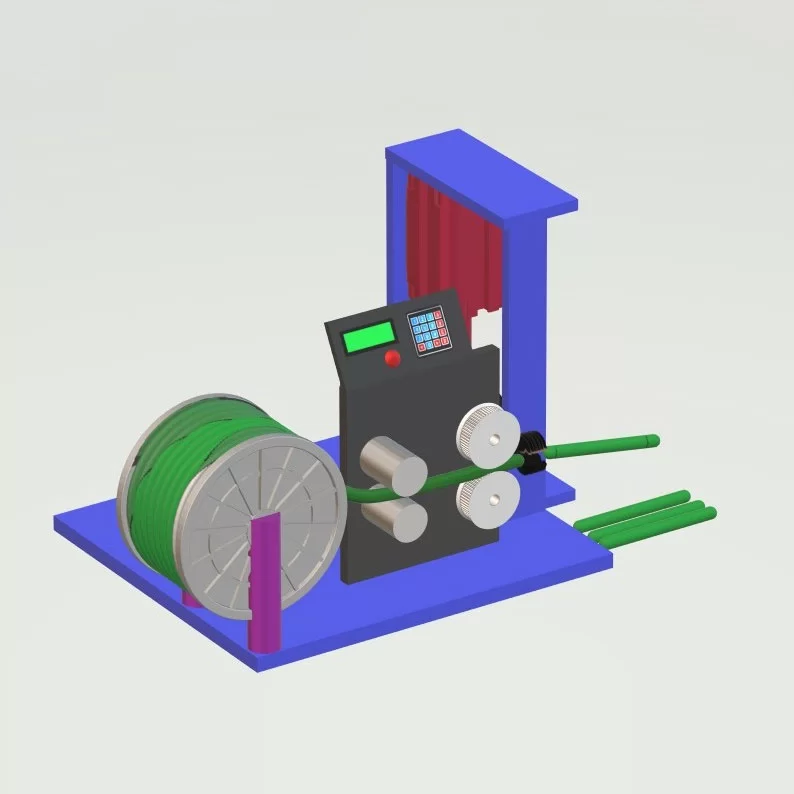

Automated Wire Cut, Strip

Wire Stripping

To facilitate your wire and cable installation, we can strip your wire for you. By removing a small section of insulation material from the conductor it covers, we can make your installation process go much smoother. Hubcircuits offers wire stripping for many electrical wire products.

Wire Cutting

In order to supply you with exactly what you need and to avoid waste, Hubcircuits will custom cut your cable to the exact length you require. By pre-cutting your wire in advance, you can save money on excess material and save time during the installation process.

Customized Wire Cutting and Stripping Capabilities

With the Hubcircuits value-added wire-cutting services, we utilize cutting-edge equipment, tools, and machinery to achieve specific length and strip requirements – ensuring consistent and repeatable results. This precision also reduces the risk of errors or damage that can occur during manual wire cutting and stripping processes while benefiting waste reduction.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.