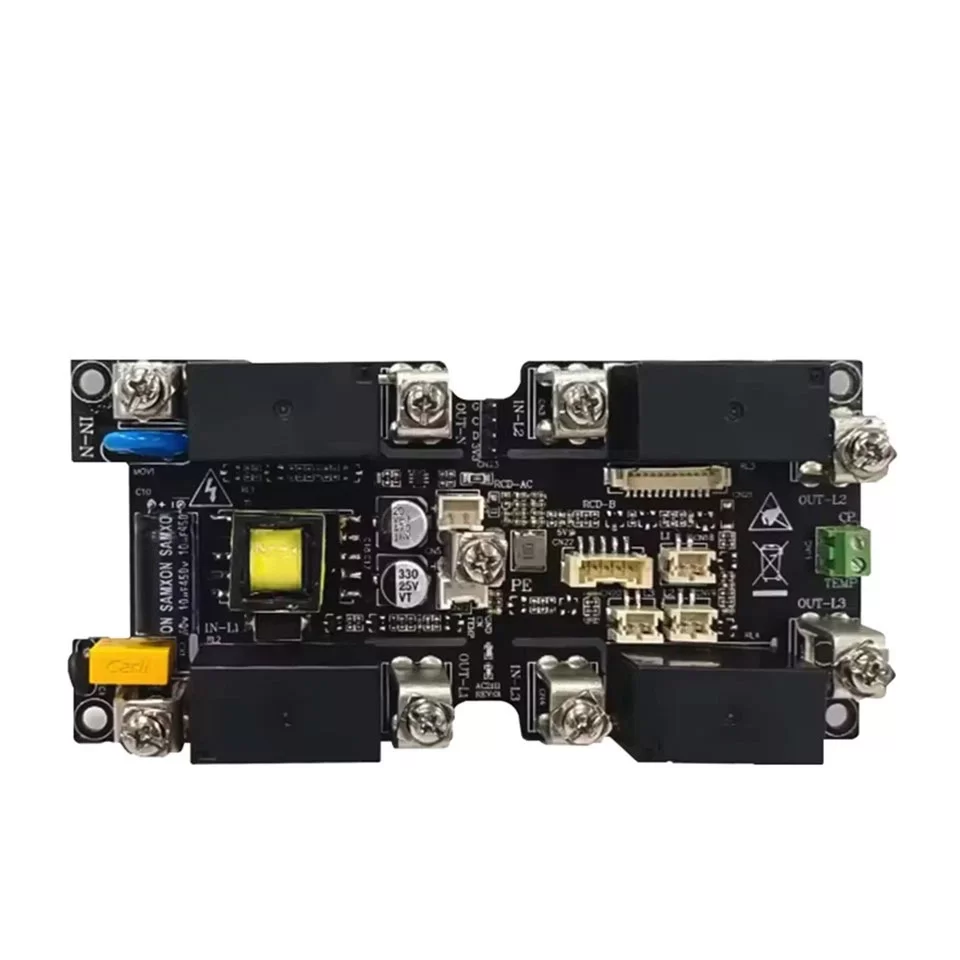

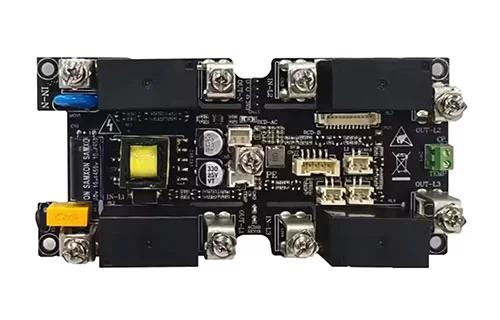

Electric Vehicle Charging PCB Assembly

PCBs for Electric vehicle

PCBs are critical in EV technology, employed in powertrains, battery management systems, onboard chargers, and vehicle control units.

EV powertrain PCBs control motor speed, torque, and regenerative braking, ensuring efficient and responsive vehicle performance.

Battery management system PCBs monitor and manage the charging, discharging, and thermal management of EV battery packs, optimizing performance and safety.

Onboard charger PCBs convert AC power from charging stations into DC power for battery charging, enabling convenient and rapid EV charging.

What is EV Charger PCB Assembly?

EV Charger PCB Assembly involves creating specialized printed circuit boards for electric vehicle chargers. This process includes careful design, precise manufacturing, and thorough assembly to ensure high performance and safety. Each PCB is rigorously tested to meet safety and compliance standards. These PCBs are important l for the reliable operation of EV chargers, ensuring they function efficiently and effectively. The Thorough approach in every Single step guarantees the production of high-quality PCBs, providing safe and reliable charging for electric vehicles.

Challenges in PCB Assembly for EV Chargers

PCB assembly for EV chargers poses several unique challenges due to high power requirements, safety considerations, and reliability demands. Here are some key challenges faced:

High Power Density: EV chargers need to deliver high power levels efficiently, requiring careful layout design and thermal management.

Thermal Management: Efficient heat dissipation is crucial to prevent overheating, which can degrade components and reduce reliability.

- High Voltage Handling: Proper insulation, clearance, and creep age distances on the PCB are essential to meet safety standards and prevent electrical arcing.

- EMI/EMC Compliance: Designing PCBs with proper shielding, filtering, and grounding is crucial to minimize EMI emissions and ensure compatibility with other electronic devices.

- Reliability under Harsh Environments: PCB components and materials must be selected carefully to ensure reliability under outdoor or harsh environmental conditions.

- Safety Standards Compliance: PCB designs need to incorporate safety features like overcurrent protection, overvoltage protection, and fault detection mechanisms.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.