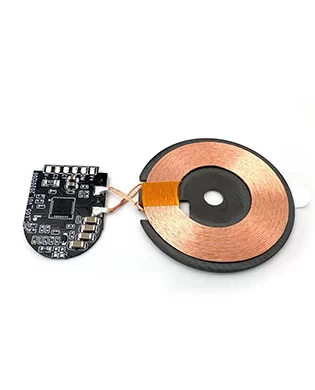

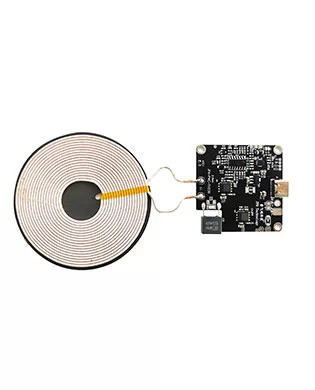

Robot Wireless Charging Module PCB Assembly

How Does Robot Wireless Charging Module PCBA Affect Charging Speed and Efficiency?

The Robot Wireless Charging Module PCBA (Printed Circuit Board Assembly) plays a critical role in determining how fast and efficiently a device charges wirelessly. The quality of the PCB and its assembly can directly impact the power delivery rate, which affects both charging speed and efficiency.

Power Conversion: A well-designed robot wireless charging module PCBA ensures efficient conversion of AC to DC power. Any loss in this conversion process can slow down charging speed.

Signal Processing: Advanced PCBA designs incorporate smart circuitry to optimize power distribution, allowing for faster and more stable charging.

Heat Management: Efficient thermal management in the wireless charger module PCBA helps maintain consistent charging speeds without overheating, which is crucial for long-term battery health.

The Role of PCBA in Robot Wireless Charging Module

The Printed Circuit Board (PCB) is the quiet hero of a wireless charger. It’s the base that holds all the key parts together. In a Wireless Charger Module PCBA, the PCB handles power changes, signal work, and safety stuff. It makes sure energy moves without touching.

Here’s how it works step by step:

1. Power In and Change: Power from a wall plug comes into the PCBA through a USB or adapter. The PCB’s circuits turn it into high-frequency AC (100-200 kHz). This makes the magnetic field for induction.

2. Electromagnetic Induction: The PCBA runs a transmitter coil. This coil is often on the board. It makes a magnetic field. The field goes through the phone’s case and hits its receiver coil. This creates a voltage that the phone turns into DC to charge the battery.

3. Talking and Control: New PCBs have tiny computers. These talk to the phone. They check power needs, spot wrong objects (like keys), and adjust power to stop overheating.

4. Saving Energy: Smart PCBA designs use resonant coupling. This boosts efficiency to 75-90%. It cuts down heat loss.

Without a strong PCB, wireless charging would be slow and unsafe. The PCBA makes it steady, growable, and follows rules.

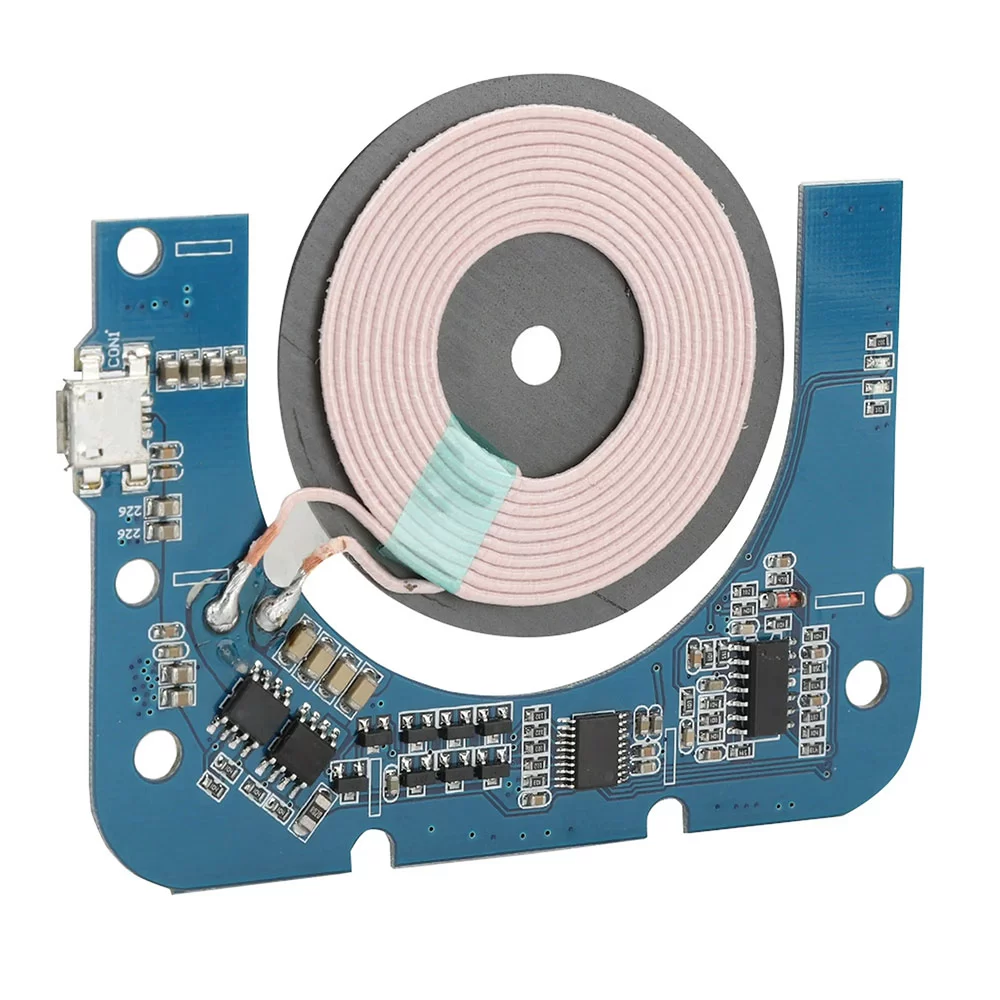

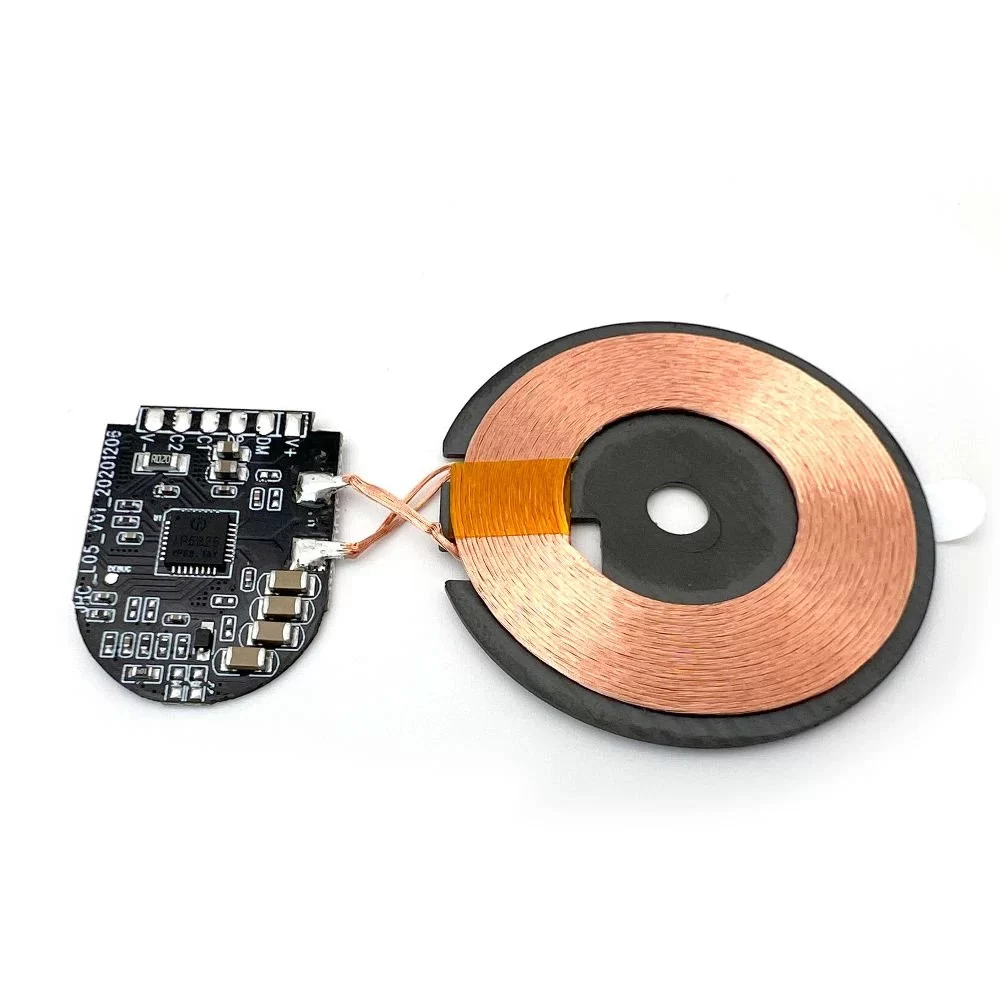

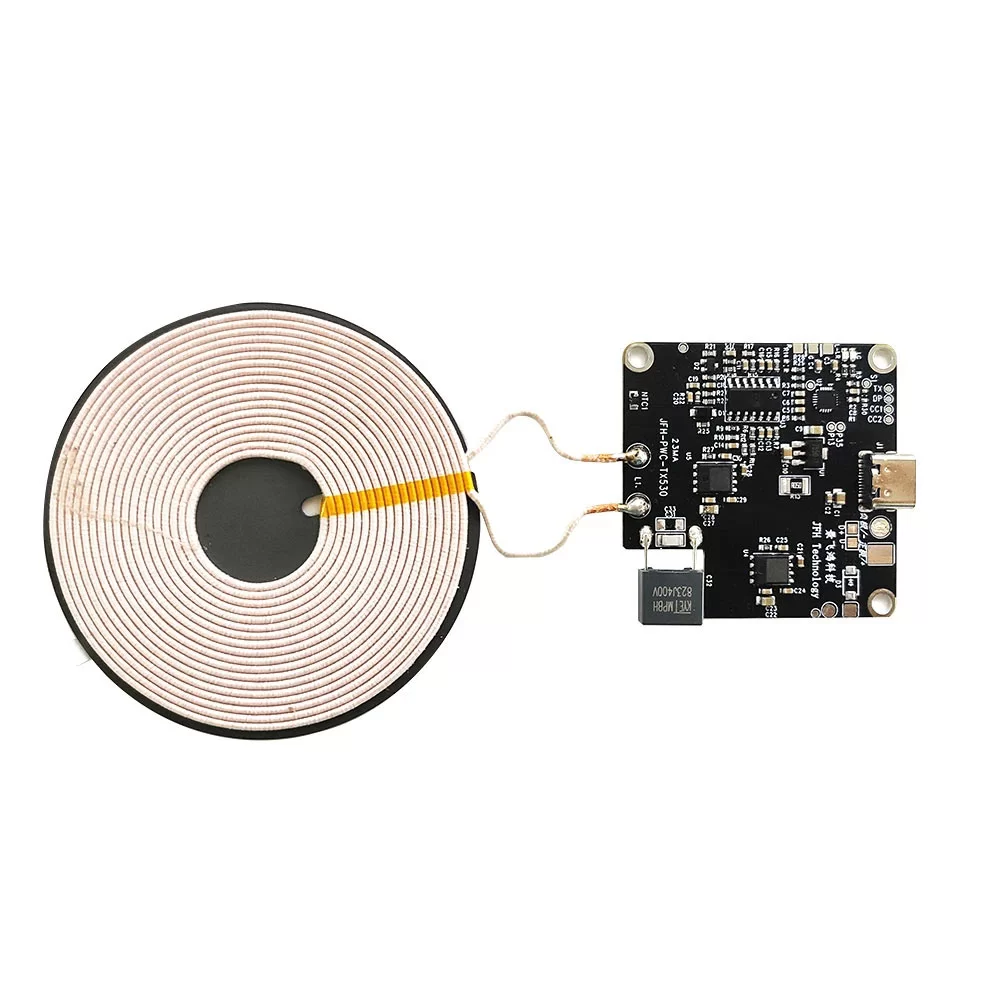

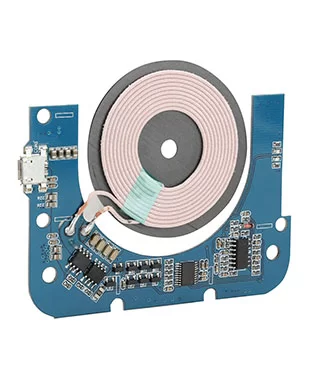

Composition of robot wireless charging module PCBA

Robot wireless charging module circuit board (PCBA) mainly consists of a circuit board (PCB) and various electronic components mounted on it, such as control chips, wireless charging coils, capacitors, inductors, and interface circuits. These components together form part of a complete wireless power transmission system, responsible for converting electrical energy into wireless signals and transmitting them to the receiving device.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.