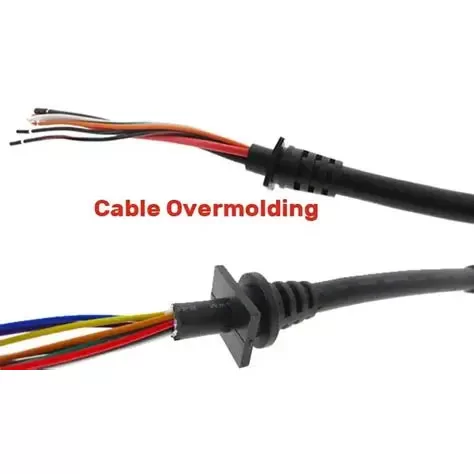

Overmolding

Cable overmolding

Cable overmolding is a manufacturing process that combines and seals a wire with a connector resulting in a single unified part. The added strength, quality, and protection overmolding provides makes it an ideal method of cable production across all industries.

About Our Services for Overmolded

From concept to finished product, the staff of Hubcircuits works to ensure that your parts are manufactured to the exacting specifications determined by your engineering team. We offer a wide variety of encapsulating materials to meet your needs including the following types:

PVCs (polyvinyl chloride)

- TPVs (thermoplastic vulcanizate)

- TPRs (thermoplastic rubber)

- TPE (thermoplastic elastomer)

- LCPs (liquid crystal polymer)

- Technomelts

Are you onthe lookout for a good memory foam mattress that combines comfort and quality?

We offers a wide variety of molded connector options such as D-subs, circular connectors (metal or plastics), mini-din, ferrites, M8/M12s, strain reliefs and mil spec components.

- We can incorporate grommets, backshells, y-blocks, fuse links, or a variety of options in your assembly.

- Our encapsulation includes low-pressure molding, potting and conformal coating allowing for encapsulation of circuit boards, connectors, switches, and box enclosers

- And for your branding needs, we can also add an imprint of your company name or logo on most overmolded cable assemblies

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.