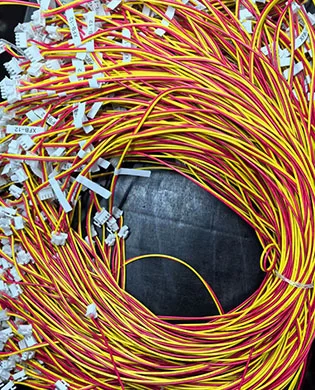

Custom Wire Harness

What is a Wire Harness?

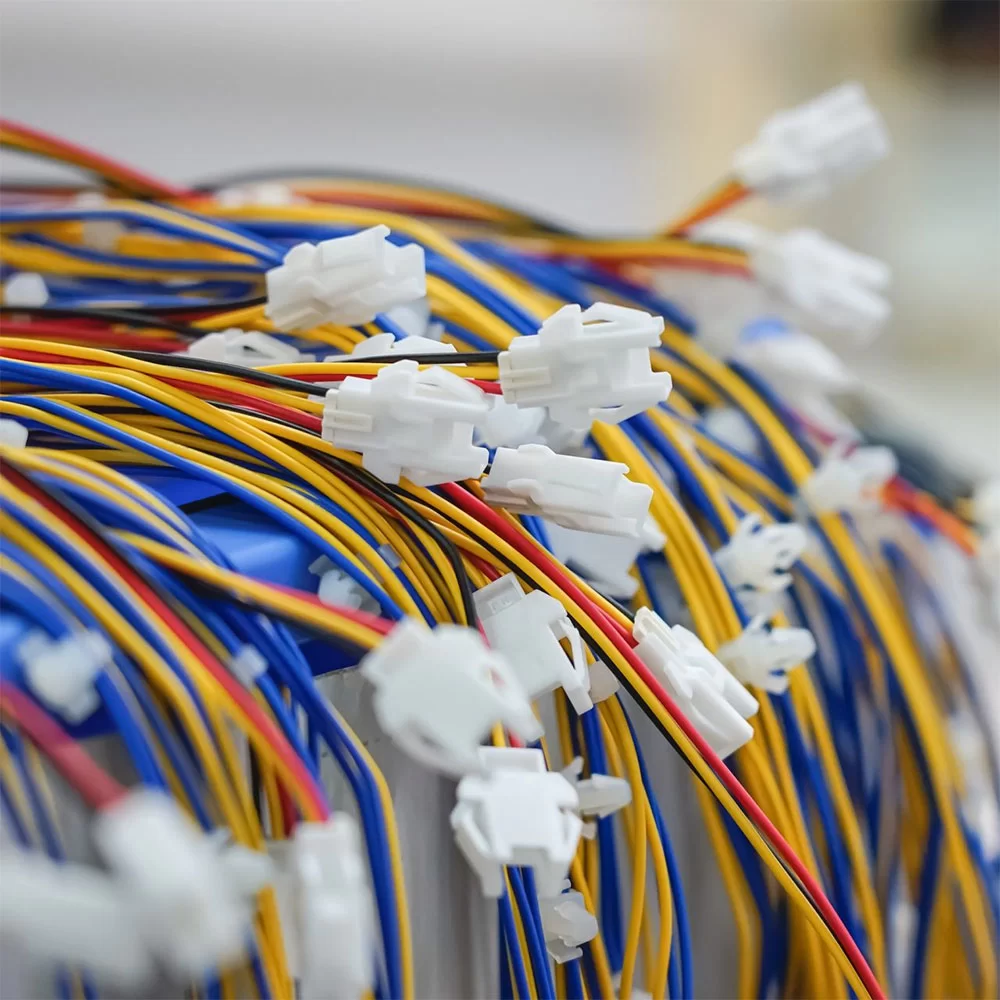

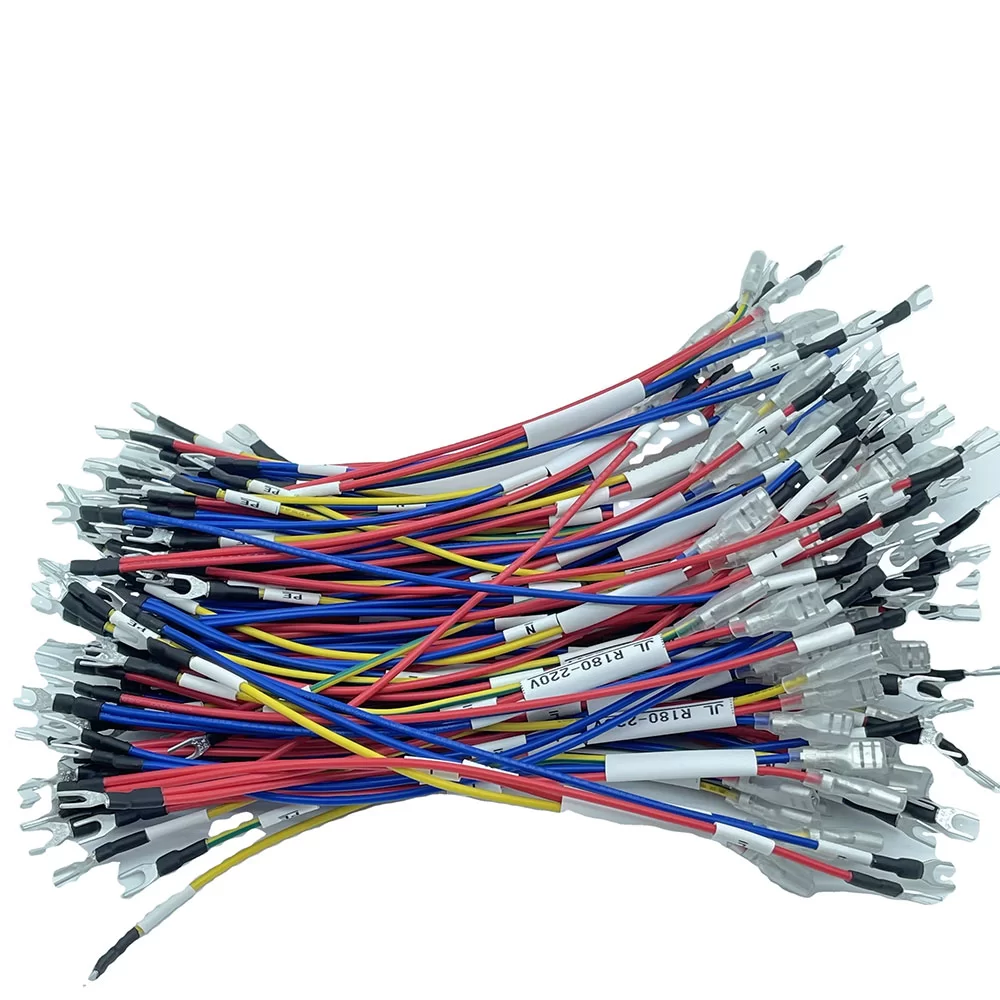

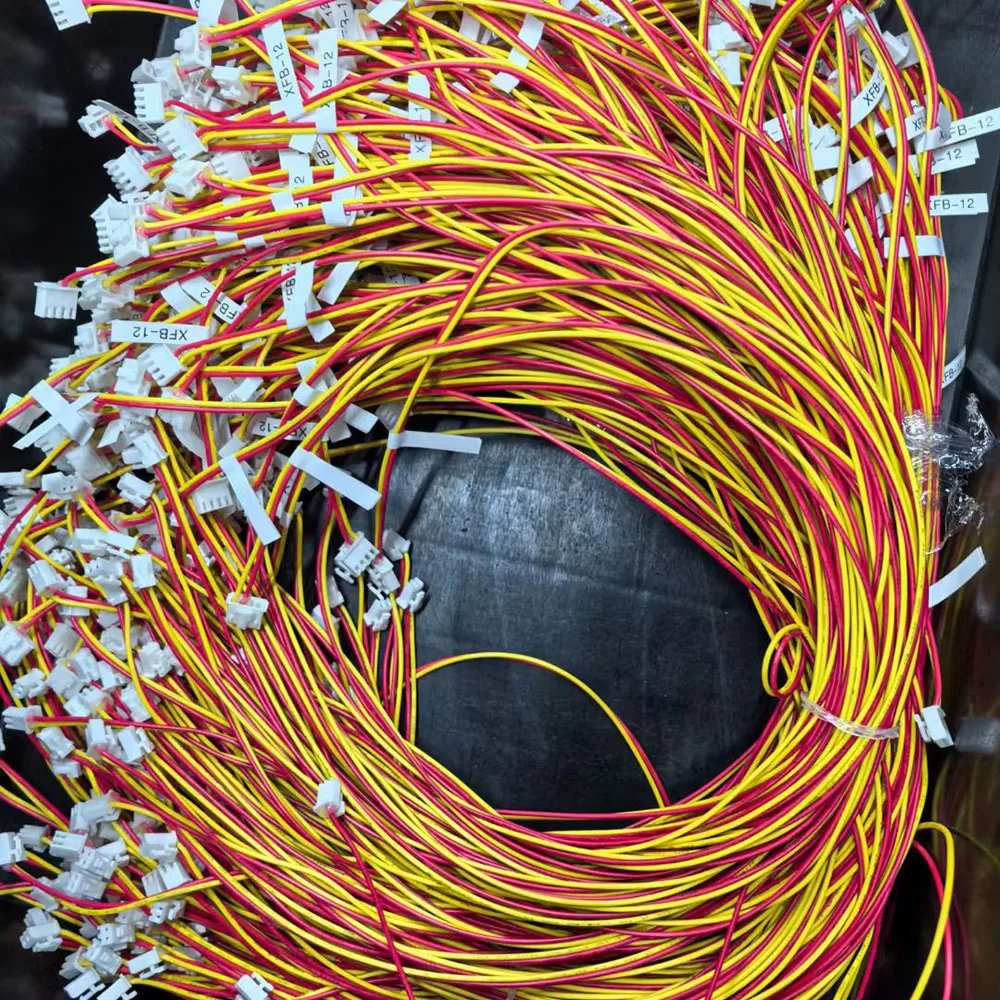

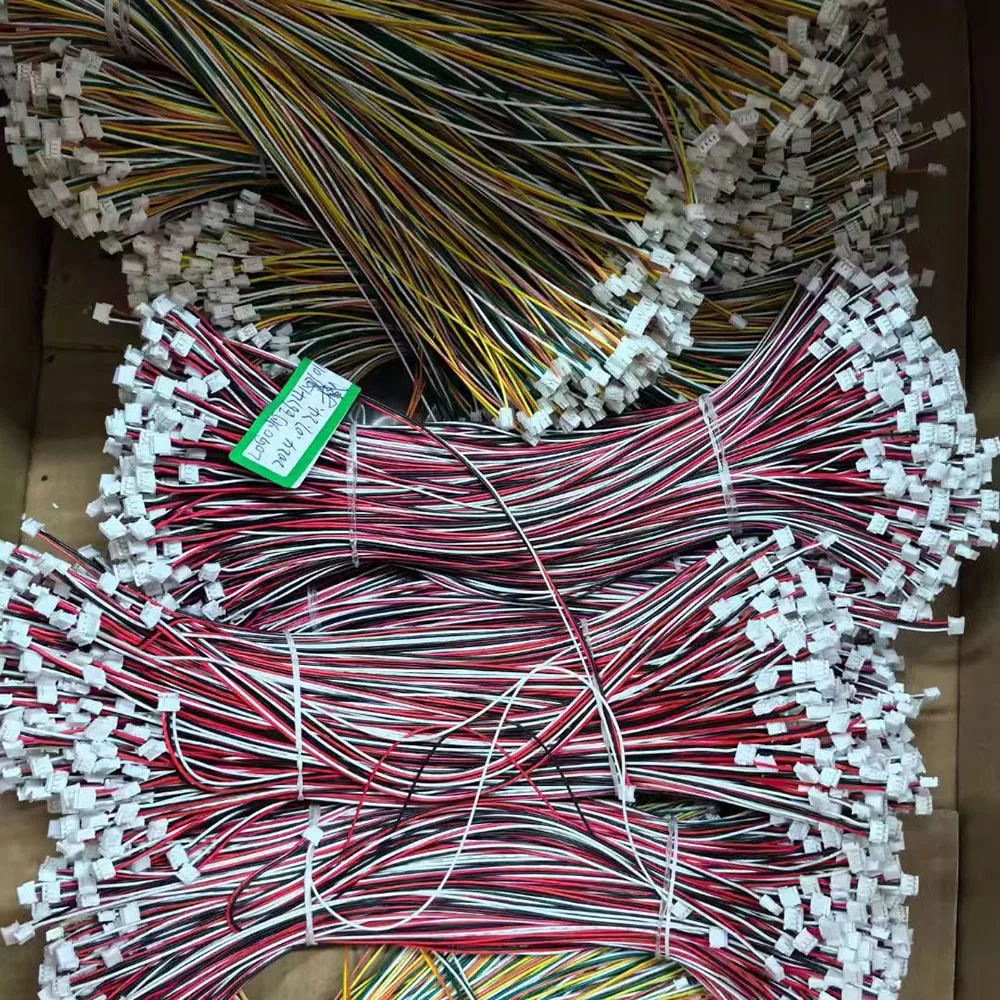

A custom wire harness is an engineered assembly of wires, cables, and connectors designed to efficiently transmit power, data, or signals within a complex electrical system. Wires are intentionally arranged to deliver optimal performance with regard to the system’s environmental demands, including spatial limitations, temperatures, and processing requirements. These critical elements streamline complex wiring configurations, reducing integration time, improving safety, and ensuring optimal performance across a broad range of applications.

The Advantage of Custom Wire Harnesses

Saves Time and Money

Custom wire harnesses are designed to fit the exact requirements of an application, which reduces the installation time and eliminates the need for additional components or modifications. This can save time and money in the long run.

- Ensures Safety and ReliabilityCustom wire harnesses are designed and manufactured to meet specific safety and reliability standards. This ensures that the wires and components are properly insulated, shielded, and protected from damage and wear.

- Improves Efficiency and PerformanceCustom wire harnesses are designed to provide a clean and organized way to connect various components, which reduces the risk of errors and improves the overall efficiency and performance of the equipment.

- Offers Customization and FlexibilityCustom wire harnesses can be designed and manufactured to meet specific requirements of an application, which allows for customization and flexibility. This means that the wires, connectors, terminals, and protective sheaths can be tailored to fit the exact specifications of the equipment.

- Reduces Maintenance and Repair CostsCustom wire harnesses are designed to be durable and reliable, which reduces the need for maintenance and repair. This can save money and increase the lifespan of the equipment.

Types of Custom Wiring Harnesses

Automotive Wire Harnesses

Automotive wire harnesses are used in vehicles to connect different electrical components, including lights, sensors, and the engine control unit. These harnesses are designed to withstand extreme temperatures and vibrations, making them reliable and durable.

Aerospace Wire Harnesses

Aerospace wire harnesses are used in aircraft to connect different electrical systems, including navigation, communication, and control systems. These harnesses are designed to meet strict safety standards and withstand harsh environmental conditions.

Medical Wire Harnesses

Medical wire harnesses are used in medical devices to connect different electronic components, including sensors, monitors, and controllers. These harnesses are designed to meet strict safety and regulatory requirements and ensure the accuracy and reliability of medical equipment.

Industrial Wire Harnesses

Industrial wire harnesses are used in a wide range of industrial machinery, including manufacturing equipment, robotics, and automation systems. These harnesses are designed to withstand harsh industrial environments and ensure the reliable and efficient operation of machinery.

Flat Ribbon Harnesses

Flat ribbon harnesses are used in applications where a large number of wires need to be connected in a small space. They are made of flat, parallel wires that are held together by a ribbon or tape.

- Coaxial HarnessesCoaxial harnesses are used in applications where high-frequency signals need to be transmitted with minimal interference. They consist of a central conductor surrounded by an insulating layer and an outer shield.

- Round Cable HarnessesRound cable harnesses are used in applications where flexibility and durability are important. They consist of round cables that are bundled together with connectors and terminals.

- Multi-Conductor HarnessesMulti-conductor harnesses are used in applications where multiple wires need to be connected to different devices or components. They consist of multiple wires that are bundled together with connectors and terminals.

- Hybrid HarnessesHybrid harnesses are used in applications where different types of wires need to be connected, such as power, data, and control signals. They consist of a combination of wires, connectors, and terminals that are designed for specific requirements.

- High-Temperature HarnessesHigh-temperature harnesses are used in applications where the wires are exposed to high temperatures, such as in engine compartments or industrial ovens. They are made of materials that can withstand high temperatures and are designed for durability and reliability.

- Waterproof HarnessesWaterproof harnesses are used in applications where the wires are exposed to moisture or water, such as in marine or outdoor environments. They are designed with specialized features such as waterproof connectors and protective sheaths.

- Customized HarnessesCustomized harnesses are designed and manufactured to meet specific requirements of an application. They can include a combination of wires, connectors, terminals, and protective sheaths that are tailored to fit the exact specifications of the equipment.

Wire Harness Assembly Process

1.Design and Planning: Engineers develop detailed schematics based on the system's electrical and geometric requirements.

- 2.Wire Cutting and Stripping: Wires are cut to specified lengths and stripped to expose conductive material for termination.

- 3.Terminal Application: Terminals are crimped or soldered onto wire ends to prepare for connector assembly.

- 4.Assembly Layout: Wires are arranged on a form board (assembly board) according to the design specifications.

- 5.Bundling and Securing: Wires are bound together using tape, clamps, or cable ties, and protective sleeves are applied as needed.

- 6.Testing: The completed harness undergoes electrical tests, such as continuity and insulation resistance checks, to ensure functionality and safety.

Key Components of a Wire Harness Assembly

Wires and Cables: Conductive materials, typically copper or aluminum, that carry electrical currents or signals.

- Connectors: Interface devices that join electrical terminations to create an electrical circuit.

- Terminals: End-point components attached to the wire ends to facilitate connections.

- Protective Sleeves and Insulation: Materials that shield wires from environmental factors such as moisture, heat, and abrasion.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.