Metal-Core Printed Circuit Boards (MCPCBs)

What is Metal-Core Printed Circuit Boards (MCPCBs)?

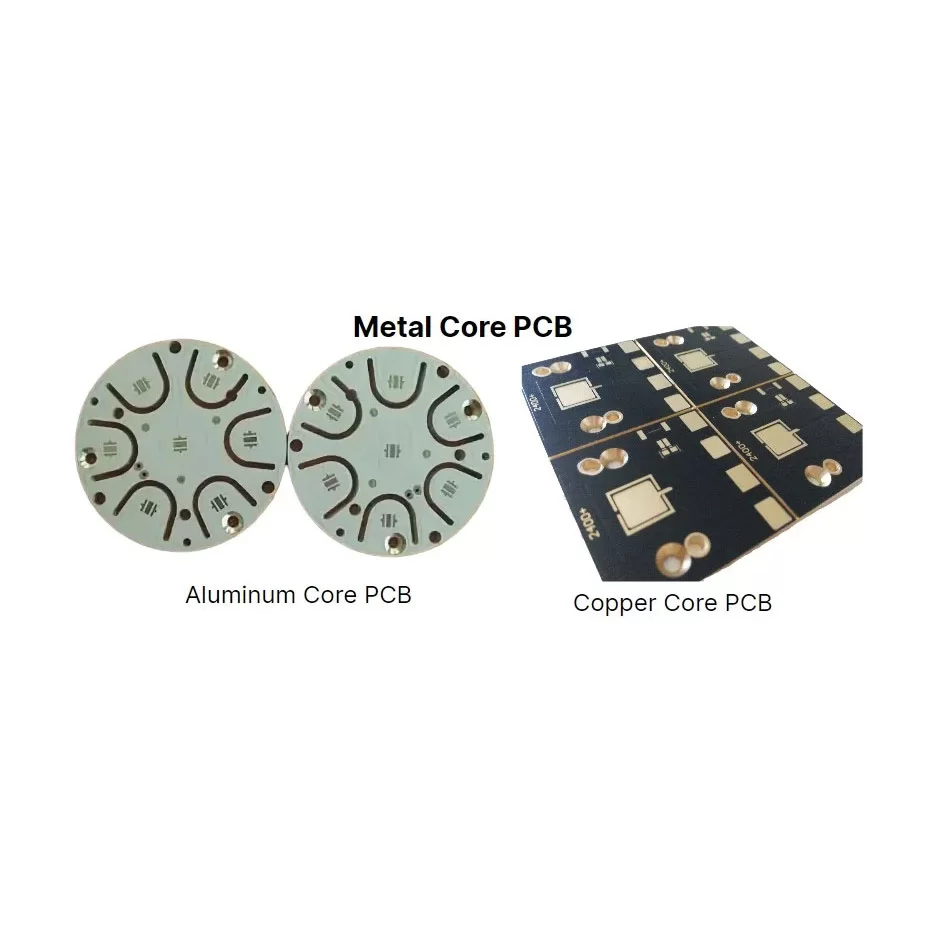

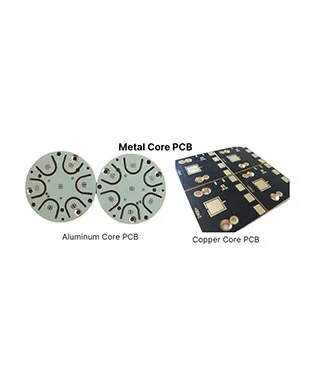

MCPCBs, also known as insulated metal substrate (IMS) PCBs or thermal clad PCBs. Its incorporates a metal base layer in its structure, typically made of aluminum, copper or steel alloys. This metal layer can quickly conduct the heat generated by the components out and transfer it to the heatsink or metal core layer, thus making the circuit run more stably and less prone to overheating. It is highly suitable for use in various high-power and high-performance electronic products.

Common materials for metal substrates

The metal substrate in metal-based printed circuit boards (PCBs) is typically made of materials such as aluminum, iron, copper, indium copper, and tungsten-molybdenum alloys.

Parts of MCPCBs

MCPCBs consist of a conductive layer, a thermal insulation layer, and a metal substrate layer.

A standard metal core circuit board is composed of:

Solder mask layer

Circuit layer

Copper layer (1oz–6oz copper, most common 1–2oz)

- Dielectric insulation layer

- Metal core layer (aluminum, copper, or steel) — functioning as a heatsink

- Optional protective coating or finish

Advantages of MCPCB

1. Superior Heat Dissipation

Because of the use of metal materials, MCPCB can quickly dissipate the heat generated by high-power device significantly enhancing the heat dissipation efficiency and making the circuit more stable.

2. High Mechanical Strength

The metal core layer (especially the aluminum material) makes the circuit board more rigid, capable of withstanding the stress caused by bending, vibration and thermal expansion and contraction, and more durable in both production and use.

- 3. Lightweight and Eco-FriendlyMCPCB are not only light and durable, but also recyclable and reusable. Especially aluminum, which is non-toxic, environmentally friendly and recyclable, is highly suitable for sustainable manufacturing.

Applications

LED lighting and high-power lamps

Automotive and industrial relays

Audio equipment and amplifiers

Sensors and package machinery

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

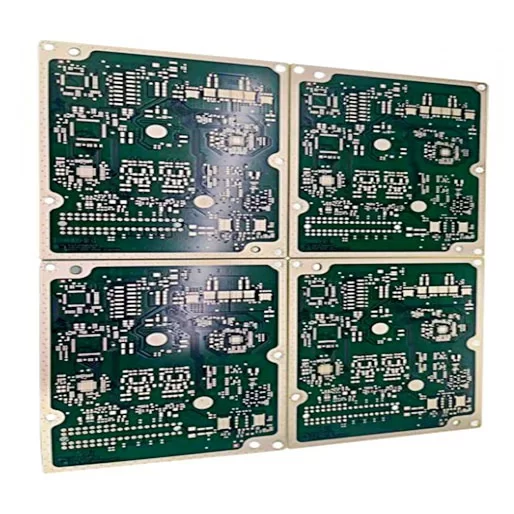

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.