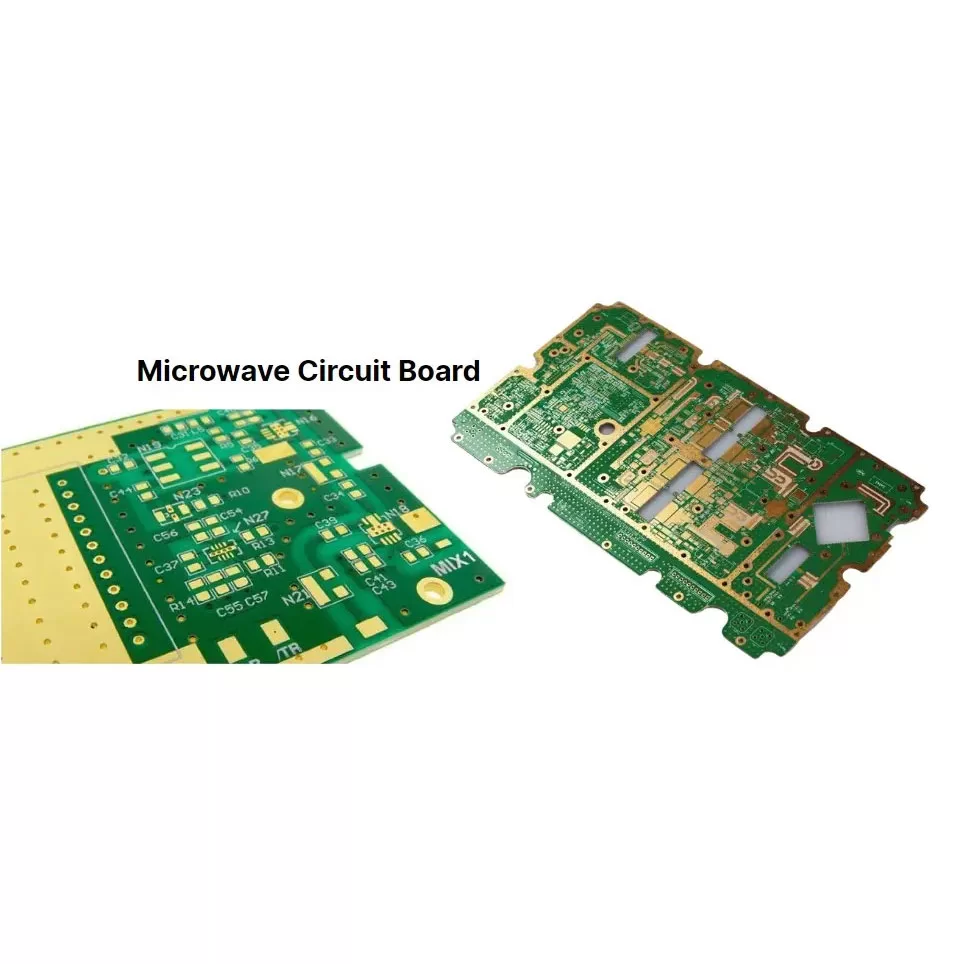

RF/Microwave PCBs

Data Sheet

Moduel: RF/Microwave PCBs

Materials: Telfon,PTFE,ceramic, Rogers

Quality standard: IPC-6012 Class 2

PCB DK: 2.0-1.6

Layer: 1 pcb layer – 36 layers pcb

Thickness:0.254mm-12mm

Ground technology: Silver,Gold,OSP

Copper Thickness:

- Ground technology: Silver,Gold,OSP

- Special process: mixed materials, stepped grooves

- Application: Antenna

Benefits

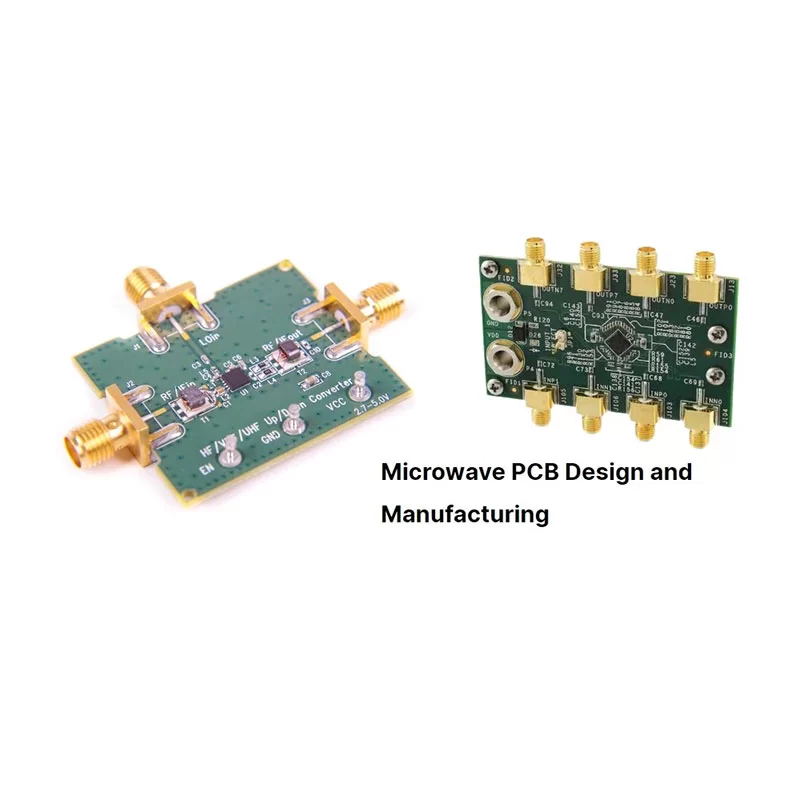

1. High signal integrity: Microwave PCB boards have one of the highest efficiencies in terms of power. Its power required to transmit the signals is low, attenuation is minimal, which can greatly improves signal integrity as well as power management of the PCB.

2. High-speed data processing:Handling high speed data is one of the USPs of Microwave and RF PCBs. Such as Wi-Fi and 5G which operate at 2.4 GHz to 6 GHz (low band 5G). Higher speeds of 50 GHz and above can only be maintained in specialised PCBs like Microwave PCBs. The ability of Microwave PCBs makes them suitable for high speed communication.

- 3. Good thermal management: The material of RF and Microwave PCBs used are of high standards and have a higher amount of copper in the body for better management of heat generated by the components on the PCB. It also eliminate noise generated by heat such as Jhonson Nyquist noise which reduces the signal integrity.

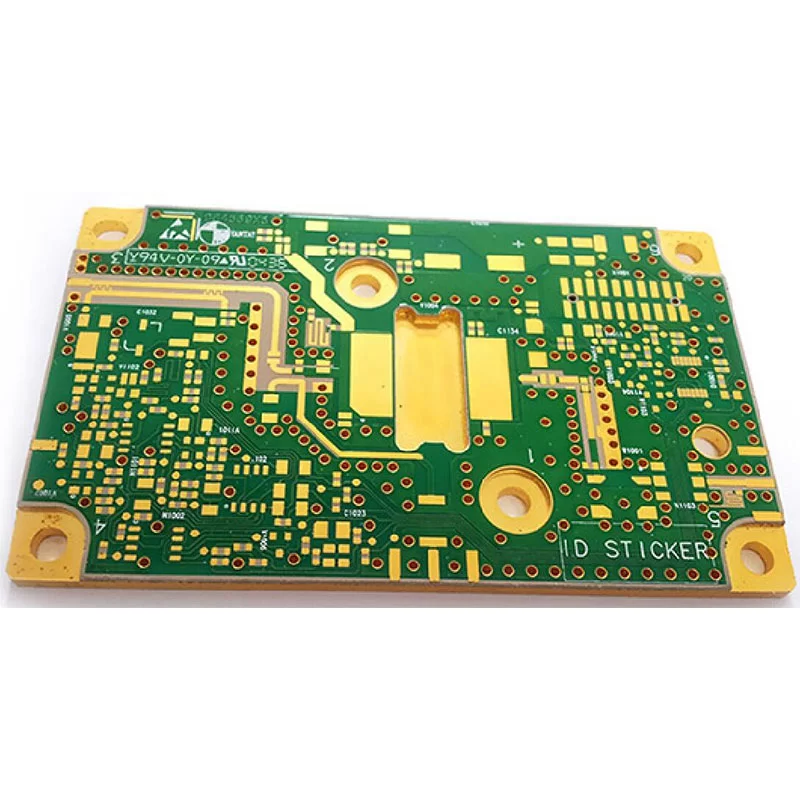

Applications

high frequency signals, transmitting or receiving wireless signals and high signal integrity are involved Radar;

Navigation:GNSS or Global Navigation Satellite System like GPS, BDS and GLONASS

- Telecommunication: Telecommunication standards like 5G, Wi-Fi, Bluetooth, and NFC

Automation Devices

Medical Machines: Medical imaging machines like MRI or Magnetic Resonance Imaging use microwave and radio frequency PCBs.

Broadcast: Broadcasting signals like antenna TV signals, FM and AM

RF/Microwave PCB material

Rogers RO4350B/RO3003 / RO4003/ RO3006/ RT/Duroid 5880/ RT5870 and etc.

Arlon/Isola/ Taconic / PTFE F4BM / Teflon material also shouldn't be forgotten.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.