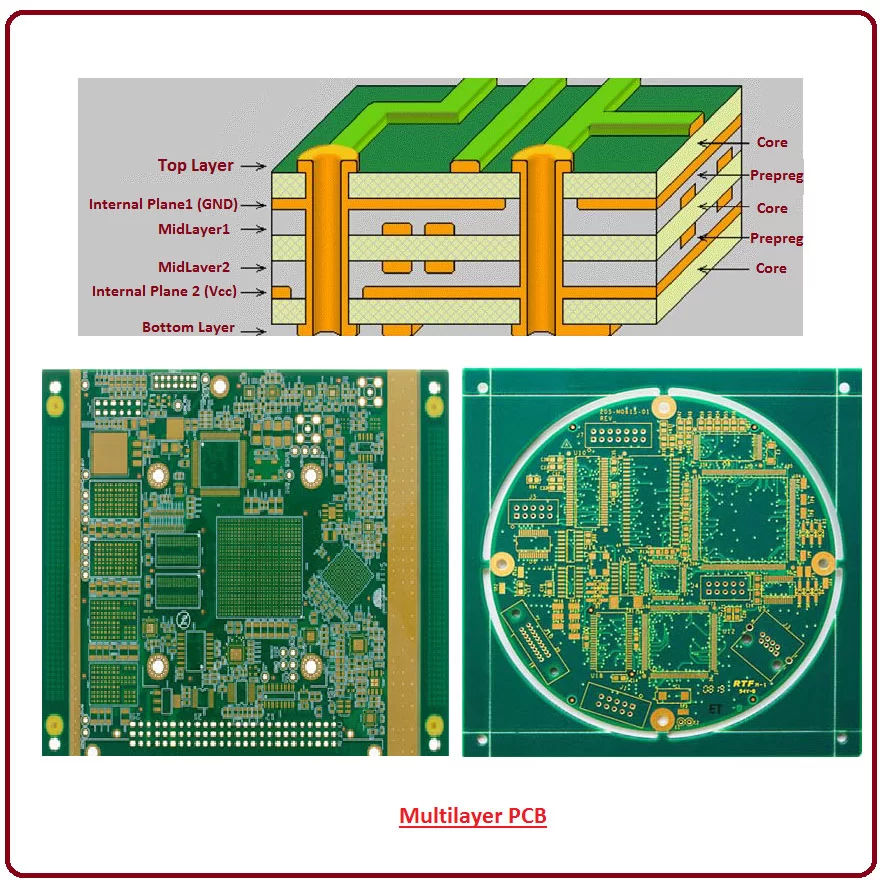

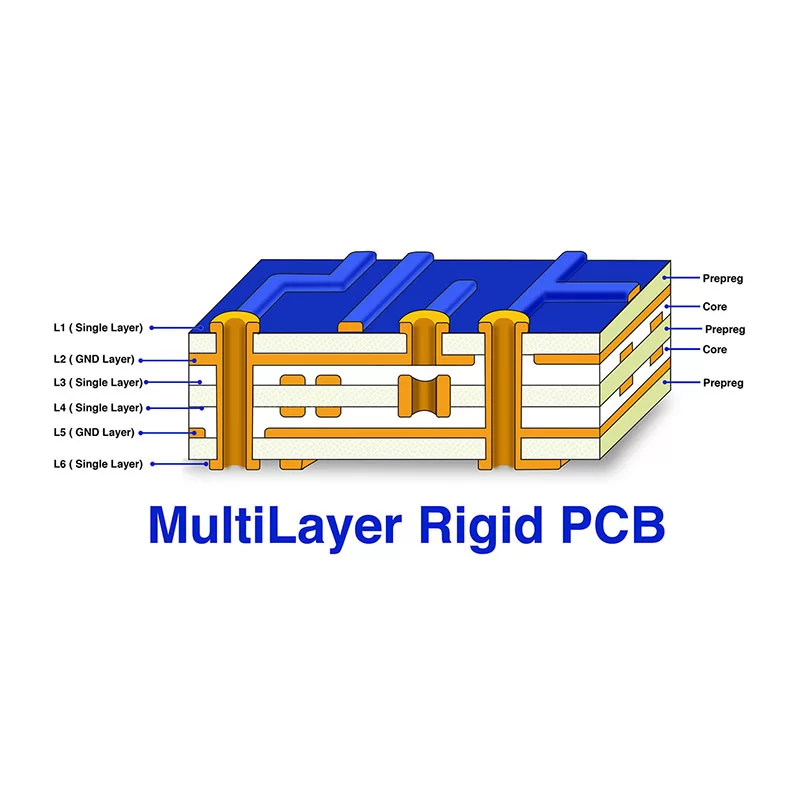

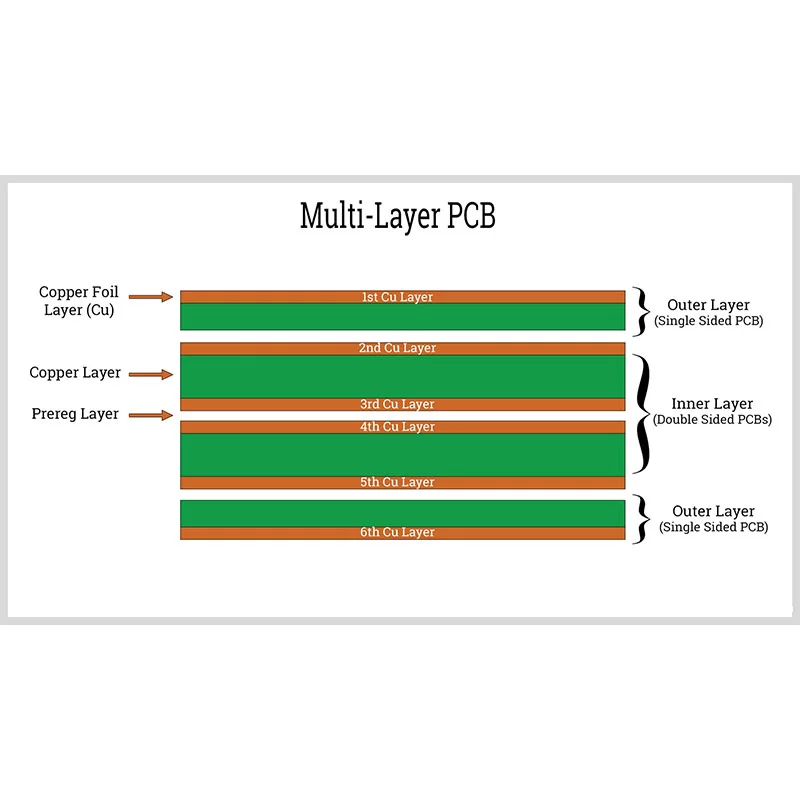

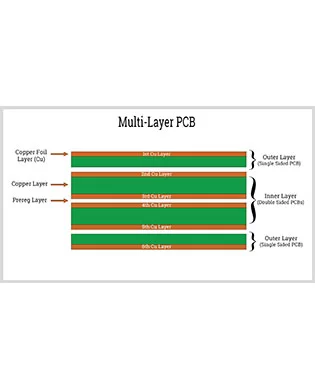

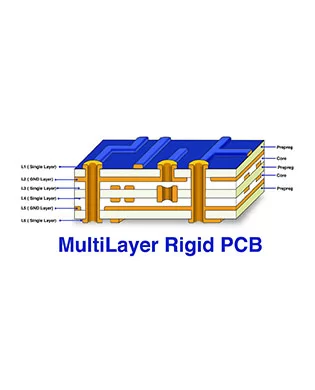

Multilayer FR4 PCB

Benefits

1.Minimize the Size of the PCB: We can reduce the multilayer PCB board size with the help of inner layers as per PCB design rules.

2.High Component Density: Multi layer PCB boards offer high component density.

- 3.More Functions: As more wires and drills are placed on multilayer PCBs, more electronic component connections are made to achieve more functions.

- 4.Powerful Performance: We can place high-power components to achieve powerful performance.

- 5.High Thermal Conductivity: Multi layer PCB boards provide high thermal conductivity.

- 6.High mechanical Strength: It provides mechanical strength. So, we can easily handle heavy parts.

Disadvantage

More Procedures: We need to get more procedures for handling them. Because the multilayer PCB manufacturing process is very lengthy.

- Higher Cost: Sometimes more costly due to the special processes required

Long Manufacturing Time: It’s taking a long time to manufacture them.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.