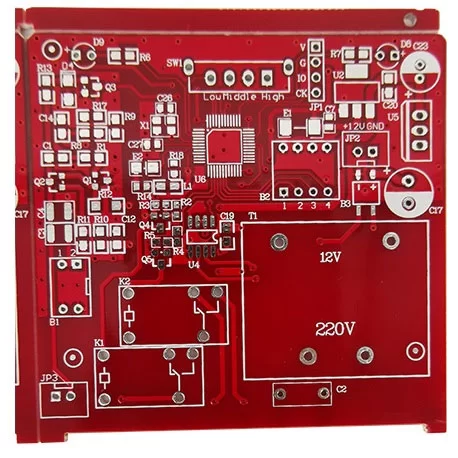

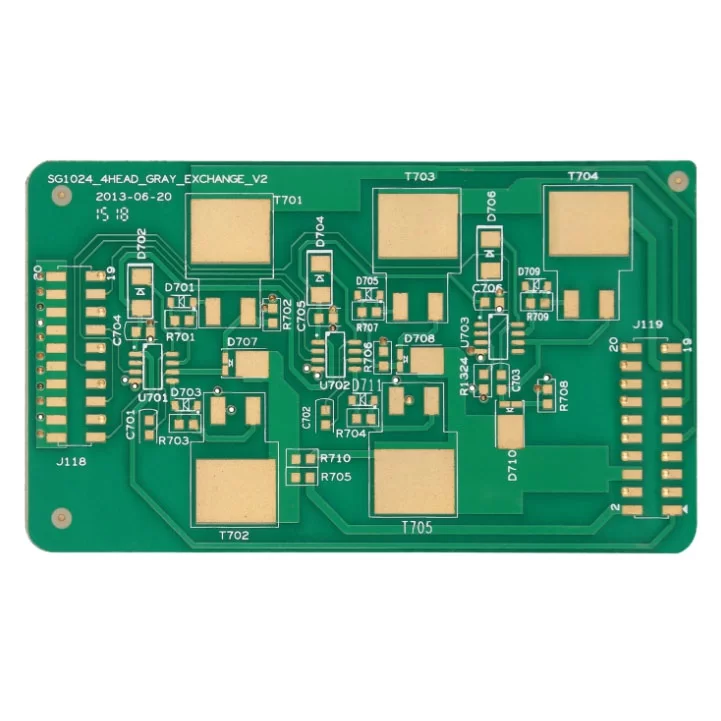

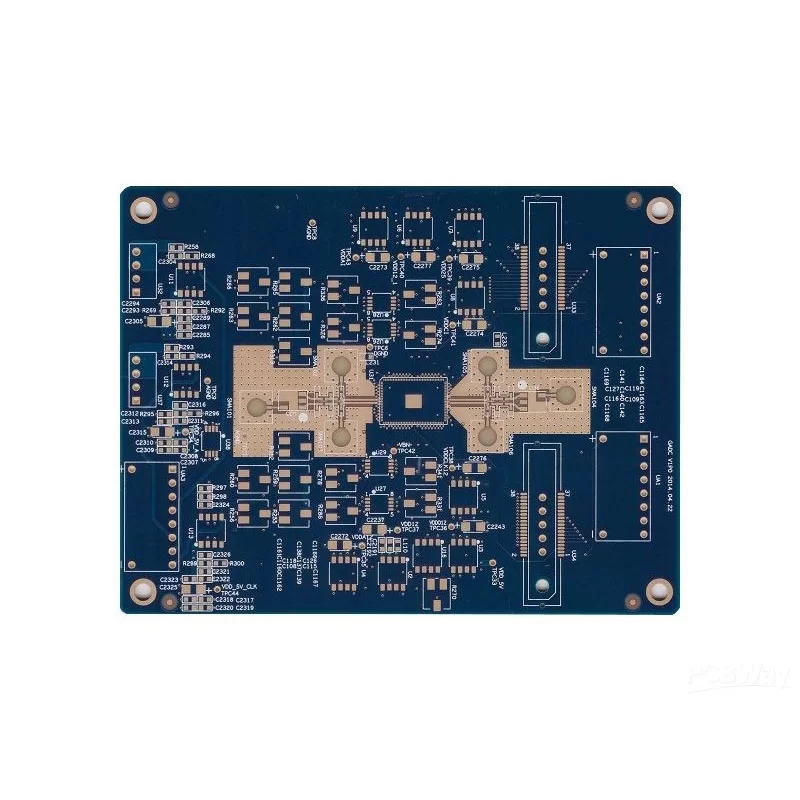

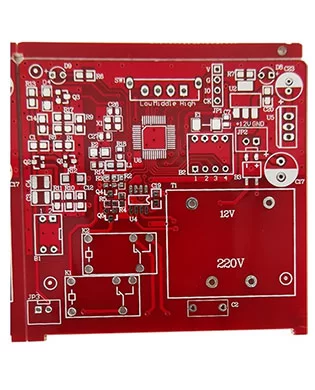

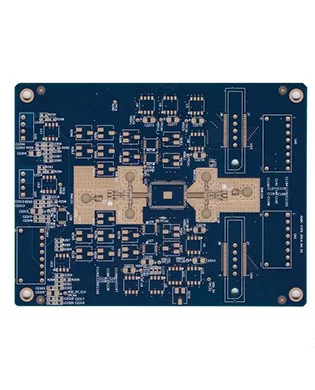

Industrial Controller PCB

Parameter

Substrate Type: High Tg FR-4/Polyimide

Copper foil thickness: 3OZ

Impedance tolerance: ± 5%

Insulation resistance: ≥ 10Ω

Dielectric loss (Df): ≤ 0.02 (1GHz)

Operating temperature: – 40 ℃~+125 ℃

Min line width/line distance: 3/3mil

Min aperture: 0.15mm (laser blind hole)

Surface treatment: ENIG/HASL

Compliance certification: ISO 9001, IATF 16949, UL94 V-0

The industrial controller PCB is the core hardware carrier for industrial controllers. As the operational hub, it not only hosts core components such as MCU/CPU main control chips and memory components but also accurately processes analog/digital signals. It integrates industrial bus interfaces like RS485 and EtherCAT to enable data acquisition, command output, and device interconnection.

With industrial-grade designs—including high-Tg copper-clad laminates and independent grounding layers—it can withstand a wide temperature range of -40°C to 85°C, vibration, and high-humidity environments. It also features anti-interference capability and easy maintenance, providing stable hardware support for industrial equipment such as machine tools and robots, and ensuring the efficient operation of intelligent manufacturing.

Benefits

High-Reliability Design

Through independent grounding layers, EMC protection, and derating design, it minimizes interference and single-point faults while extending equipment service life.

Wide Environmental Adaptability

It utilizes high-Tg copper-clad laminates and special surface treatment, withstanding harsh operating conditions such as a wide temperature range (-40°C to 85°C), high humidity, and vibration.

Ease of Maintenance

Test points and clear silkscreen markings are incorporated, facilitating rapid fault location and reducing operation and maintenance costs.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.