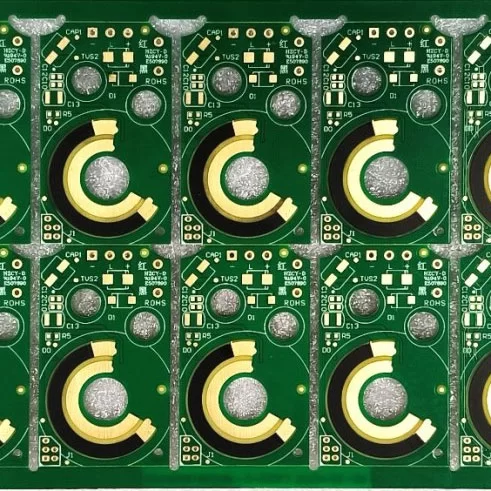

Carbon Conductive PCB

What are Carbon Ink Printed Circuit Boards?

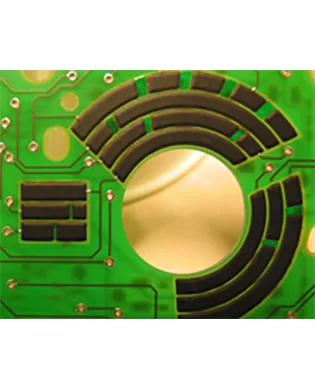

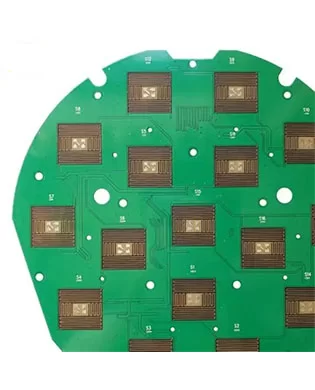

Carbon ink PCB, also called carbon conductive PCB, are circuit boards with carbon ink applied onto the copper pad, replacing some of the more common solder plating such as Electroless Nickel Immersion Gold (ENIG) or Hot Air Solder Leveling – Lead Free (HASL).

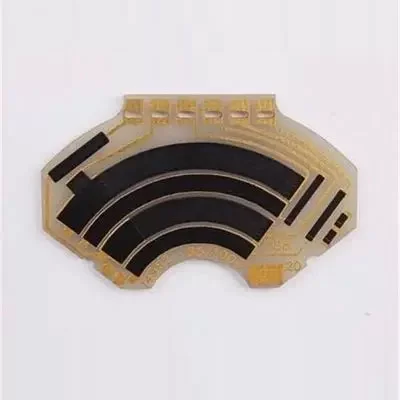

The carbon serves as a conductor to connect two traces on PCB board, and a resistor between the traces or traces and components. The key factor in carbon ink PCB production is to control the printing, baking and resistance control. The carbon ink can be printed onto flexible circuit, rigid-flex board and rigid PCB, such as polyimide, polyester, FR-4, FR-5 and PTFE laminates. Carbon ink can offer resolutions as fine as 100μm trace width and spacing.

Now the market’s requirements for PCB board production costs have dropped repeatedly, and it is a general trend to use carbon oil keys to replace the current expensive gold keys. Carbon oil board is a relatively common surface treatment method for single and double PCBs. Through a series of inspections, tests and aging tests, and other technical processes, the PCB can work reliably for a long time.

Common Uses of Carbon Ink Printed Circuit Board

Carbon Ink PCBs are widely used for printed circuit boards deployed in the following applications:

RF Shielding

Keypad

Keyboard

Remote Controller

Automotive Vehicles

Industrial Engine Control

Welding Equipment

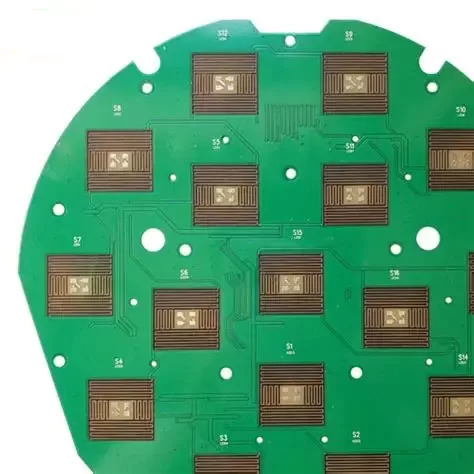

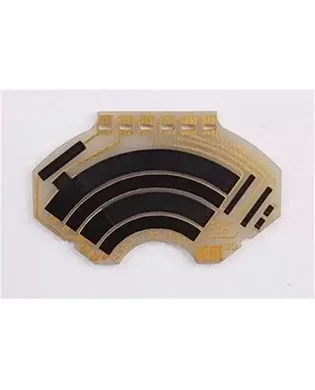

One particular area where Carbon Ink PCBs excel at is the application of rubber keypad, commonly found in television remote controllers, garage door controllers, etc. A typical conductive rubber keypad involves creating angled webbing around a switch center. When the switch is pressed, the webbing deforms and produces a tactile response. As soon as the switch is no longer under pressure, the webbing returns to its neutral position.

The carbon tactile key comes into play when making electronic switches, as a carbon pill is placed at the switch center’s base. If you have ever taken apart (or broken) a TV remote controller, you may notice on the printed circuit boards, under each rubber that you used to press, is a little circular dot that can be pressed down ever so slightly. This carbon tactile key contacts the PCB when the web is pressed; a rather simple and ingenious solution that is both durable and cost-effective.

Why Use Peelable Solder Masks in PCB Manufacturing?

1.The composition of carbon oil

Carbon oil is mainly composed of synthetic resin, hardener, and carbon powder.

The synthetic resin plays a role in adhesion (equivalent to a carrier).

The hardener plays the role of curing.

Carbon powder plays a conductive role (graphite powder can be added, but with high cost).

Some suppliers add a little silver oil into the carbon oil to obtain lower resistance and higher conductivity.

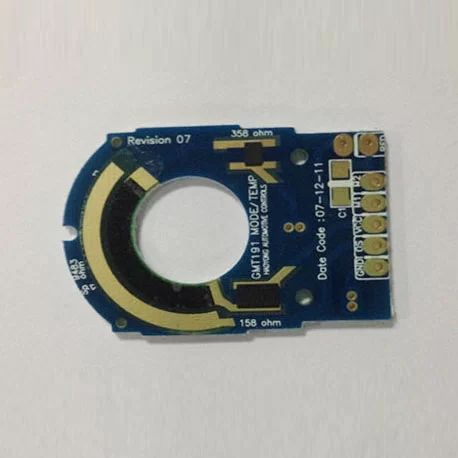

- 2.The resistance of carbon inkThe resistance of carbon oil is generally expressed by square resistance. Some use ohms per square centimeter (Ω/cm²), and some use ohms per square centimeter (Ω/□). Most suppliers now agree to use Ω/□.Square resistance refers to the resistance value of any square carbon film on the opposite side, which is related to the thickness and composition of the carbon oil. (It can be analyzed from the figure below).According to Ohm’s law:R=ρ*L/S (R=square resistance, ρ=resistivity, L=carbon oil length, S=side area=thickness*width=r*m)So R=ρ*L/r*m(if L=m)So R=ρ*rIt can be seen from the above formula that when the surface impedance is L=W (when the length and width are equal, any square “□”), it can be expressed by “Ω/□”. But it must be stated at what thickness is the “Ω/□” value. Generally, the supplier will indicate ≤ 30Ω/□ at 15um or 25um.

- 3. The resistance control of carbon oilThe resistance of carbon oil is only related to its composition and thickness. Therefore, to obtain a satisfactory resistance requirement, we must follow three aspects.1) A reasonable square resistance carbon oil that meets the process requirements.2) A reasonable thickness (0.01-0.025mm) should be achieved after printing.3) Baked fully (oven: 150℃ to 170℃, for 30-60 minutes; infrared oven: 150℃, for 15 minutes).In the actual operation process, the temperature is high, the time is long, and the square resistance is low. It is important to choose a reasonable temperature and time without affecting the substrate.

The characteristics and uses of carbon ink PCB

The carbon ink has strong adhesion, peeling resistance, and strong abrasion resistance, which can reach ≥ 1 million times, and the resistance change rate is ≤ 10%. The square resistance of conductive paste is relatively large compared to other metals. The square resistance of the current carbon oil board can generally be controlled at ≤ 20 ohms, but the cost is low with a high-performance cost ratio. The conductive paste is a crucial material for electronic component packaging, electrodes, and interconnection of electronic components. It mainly includes two types: burn-in conductive paste and curing conductive adhesive (conductive ink).

Carbon ink board use:

Carbon oil board is mainly used in film circuits, mobile phone soft circuits, medical devices, communication equipment, automotive electronics, smart label RFID, and many other industries. In the circuit board industry, it is mainly used for calculators and remote controls. It can replace copper-plated holes, silver slurry hole fillings, and the copper slurry hole filling process. Environmental protection and the low cost of carbon slurry hole filling is the mainstream trend of the development of circuit boards. Currently, Microsoft uses carbon oil filling holes on the power supply board, which can completely replace the double-layer board with copper-plated holes.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.