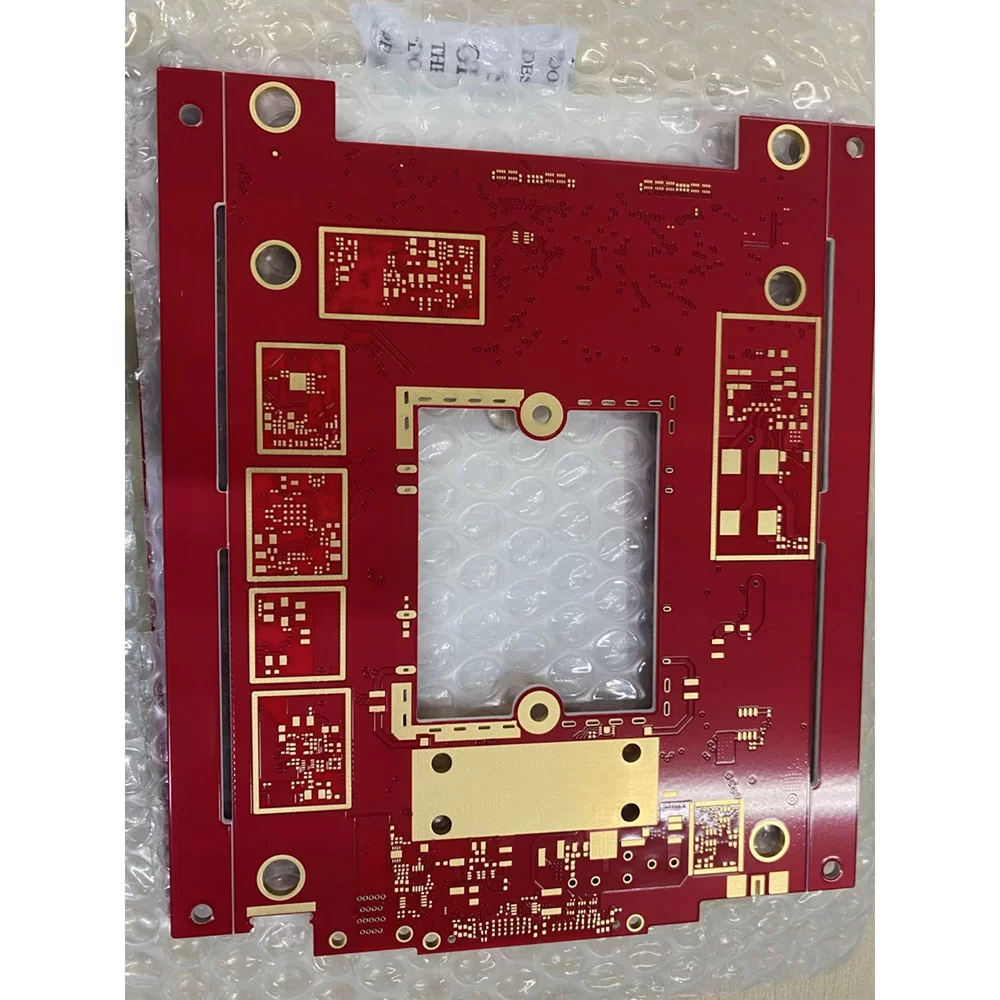

High TG FR4

What's High Tg PCB?

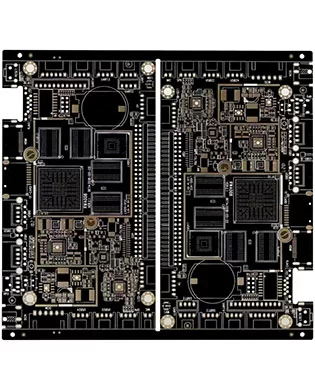

High Tg PCBs are PCBs made up of materials that combine high dimensional stability (rigidity) with a high glass transition temperature (Tg). This PCBs are one of the unique PCBs that can withstand and maintain performance at elevated temperatures.

The temperature of High Tg PCBs can range from 170 °C to 260 °C. The temperature range of standard PCBs is only about 130 °C to 140 °C. They are available in different types – single-layer, double-layer, or multilayer and can be used in all sorts of setups.

Advantages

1.Enhanced Thermal Stability:As compared to 130-150°C for standard FR-4, high Tg PCBs have a Tg exceeding 180°C. This means they can handle higher operating temperatures without warping, softening, or experiencing electrical failures.

- 2.Excellent Chemical Resistance:High Tg materials usually use special epoxy resins or strong polymers that can resist a wider range of chemicals compared to the standard FR-4 material with its brominated epoxy resin. These materials have a denser structure, which means they don't let corrosive liquids seep in easily and helps protect copper traces and internal parts from damage.

- 3.Better stability:In addressing moisture and heat challenges, PCBs with higher Tg levels work better. So, using a high Tg PCB substrate is a safer bet.

Application

Automotive Electronics

- Oil and Gas Industry

- Aerospace and Defense

- Industrial Electronics

- Medical Applications

- Electronics Test Equipment

- Consumer Electronics

Disadvantages

Signal Loss

The dielectric properties of high Tg PCB materials differ from those of standard PCB materials. This increases the likelihood of high-frequency signal loss and may compromise the performance of high-speed electronic circuits.

- Limited FlexibilityHigh Tg PCBs are rigid, but their flexibility and mobility are inferior to ordinary PCBs. This is a limited for applications that require a bit of flexible circuit fabrication.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

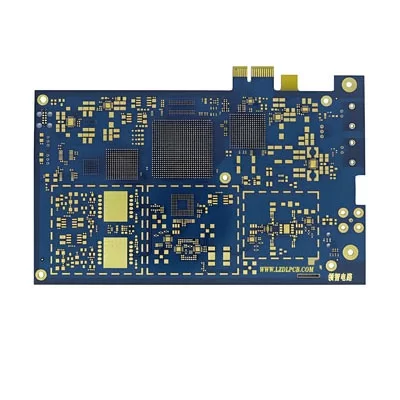

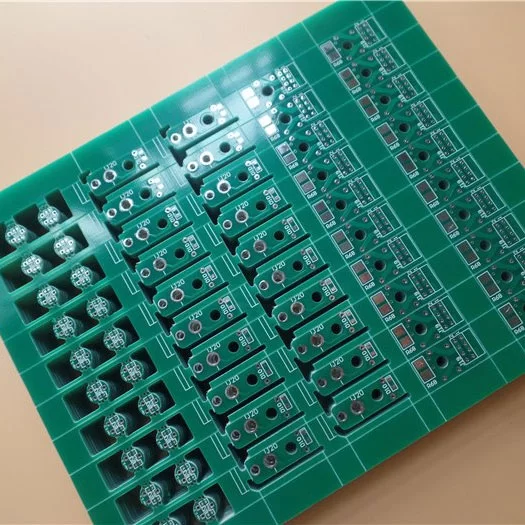

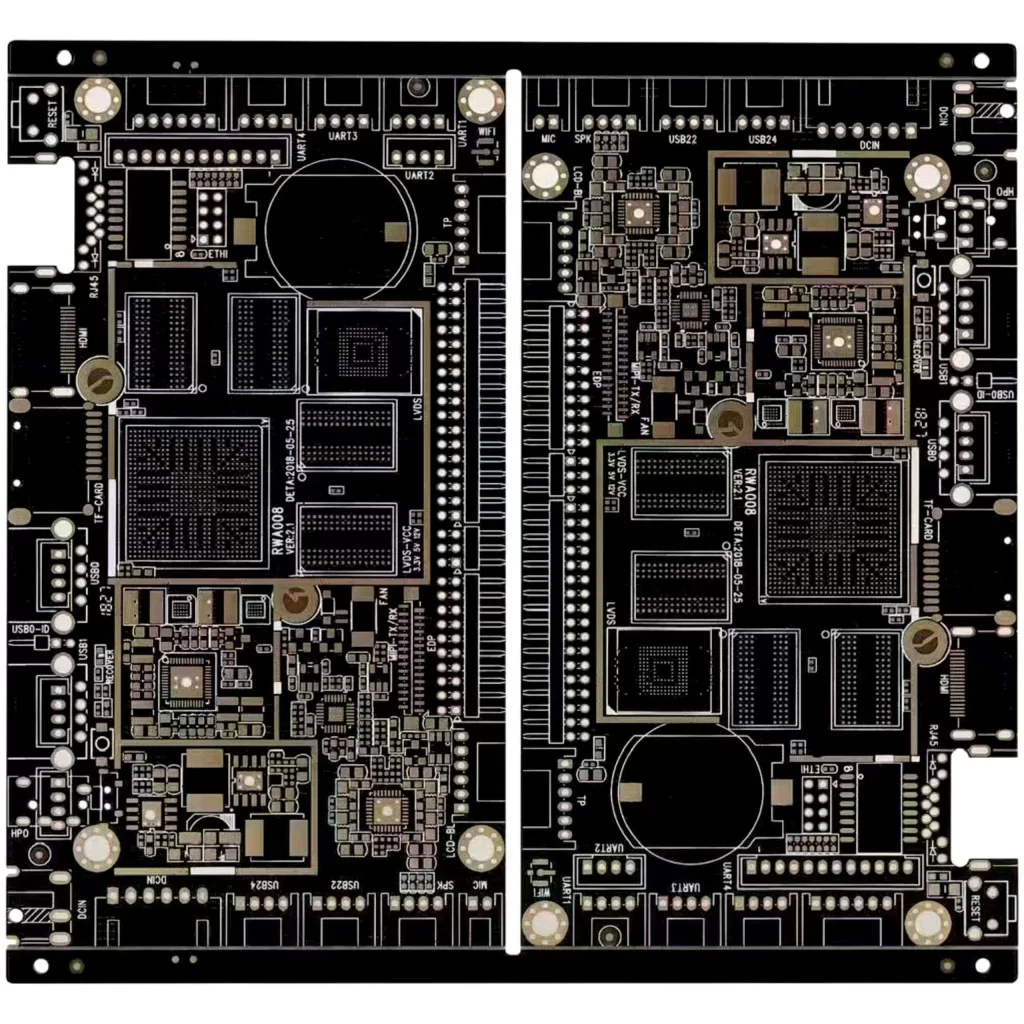

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.