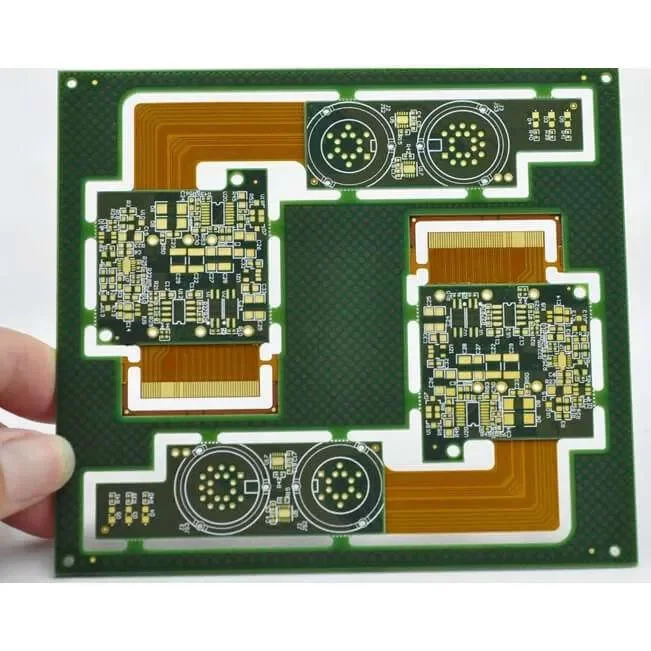

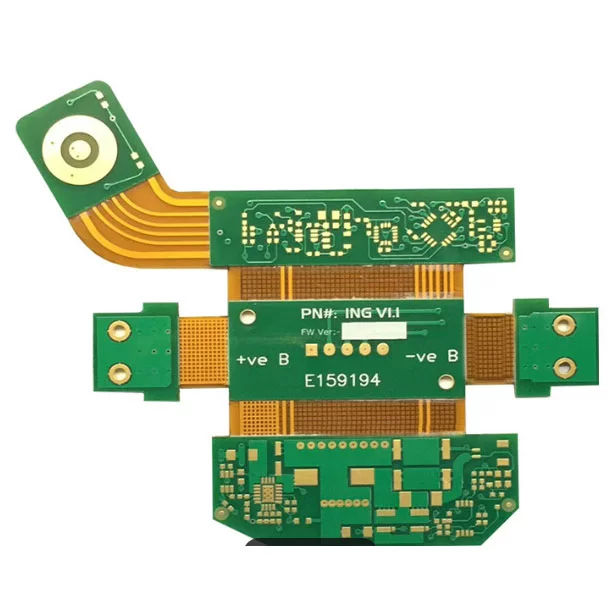

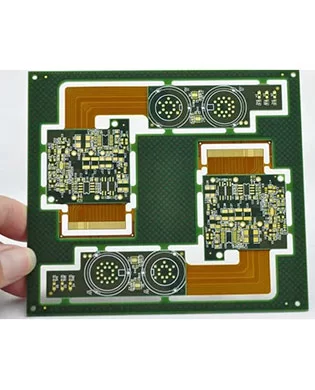

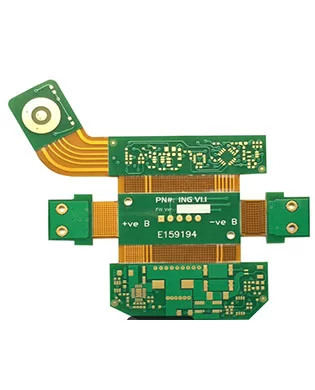

FR4 Semiflex PCB

What's Semiflex PCB?

Semiflex PCBs are a unique type of PCB that integrates flexibility into a rigid PCB (typically using FR4 substrate). They achieve flexibility by thinning specific sections—these thin areas can bend but not break, but with limited flex cycles to avoid damaging the PCB’s structural integrity. The rigid sections of FR4 semiflex PCBs are identical to standard rigid PCBs and usually the components are only placed on rigid section.

Semiflex PCBs Advantages

1. Performance

Offers rigid flexibility to maintain stable folded geometry.

Fits smaller enclosures and enables complex maintainable shapes.

Improves signal integrity by reducing impedance mismatch (vs. cables/connectors).

Enhances durability with strong resistance to vibration and shock.

2. Cost-Effectiveness

More affordable than rigid-flex PCBs and flex PCBs.

Saves costs by using only one type of material.

Eliminates expenses for cables, connectors and multi-PCB setup/engineering.

3. Assembly

Reduces the number of PCBs and cables needed for the solution.

Enables "place-and-use" component installation, simplifying assembly.

Shortens the overall assembly time of the entire system.

Disadvantages of Semiflex PCBs

Limited Bending Cycles: They only support a limited number of bends before visible damage occurs. Frequent bending is not recommended.

- Challenging Design: Designing semiflex PCBs is difficult due to the numerous parameters that need consideration. Both PCB layout and component placement require careful planning.

- Short Flexible Sections: Unlike rigid-flex PCBs, they are unsuitable for applications requiring long flexible segments—this would compromise mechanical integrity.

Applications

Camera Flash

- Handheld medical devices

- Automotive

- Compact speakers

- Curved screen monitors

Cautions for Designing & Using Semiflex PCBs

1. Component & Vias Placement

①Never place vias, components, or solder joints on flexible sections. Placing them here would reduce flexibility and raise the risk of physical damage during bending.

②Avoid component placement at the edges of rigid sections to prevent short circuits from component proximity and protect components from edge stress.

③Keep the weight of rigid sections with components balanced to ensure overall structural stability and avoid uneven stress on flexible parts.

④Heavy components (e.g., transformers, batteries) should be avoided, as they can cause structural imbalance and increase the risk of flexible section breakage.

- 2. Layer & Routing Management①Minimize the number of layers in flexible sections to decrease thickness and stiffness, thus lowering warpage risk.②Route traces in flexible sections symmetrically and as spread out as possible—this prevents local stress concentration and reduces signal distortion when bent.Proper layer and routing management is essential for maintaining signal integrity (SI) of high-frequency and high-speed signals.

- 3. Flexible Section Bend RadiusAlways confirm the bend radius with usbefore bending. An excessively small radius can lead to copper foil cracking or substrate delamination, damaging the PCB.

- 4. Application ScopeRestrict use to static bending scenarios—bend once during installation and never re-bend. Semiflex PCBs have limited flex cycles, so dynamic or repeated bending will quickly cause damage.

- 5. Copper Content in Flexible SectionsMake sure flexible sections havesufficient copper to conduct the expected current without overheating. Inadequate copper undermines thermal management and may result in overheating.

- 6. Mechanical Stress ControlBend semiflex PCBs gently, as excessive force can damage flexible sections by causing substrate breakage or copper foil detachment.

Semiflex PCBs vs Rigid Flex PCBs

Rigid Flex PCBs | Semiflex PCBs | |

Substrate Materials | Rigid sections (FR4) + flexible sections (polyimide) — different substrates | All sections use the same substrate (FR4); flexibility via thinning rigid material |

Flexibility Level | High and durable (dedicated flexible substrates) | Limited (only from thinned rigid material); lower than rigid flex PCBs |

Cost | More expensive (dual substrates + complex manufacturing) | Significantly cheaper (single substrate + simple thinning process) |

Bending Performance | Suitable for dynamic bending; supports hundreds to thousands of cycles | Only for static bending (one-time shaping); ≤50 cycles before damage |

Typical Applications | Portable devices (repeated folding), medical equipment | Static installations (e.g., small enclosures), simple bent structures |

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.