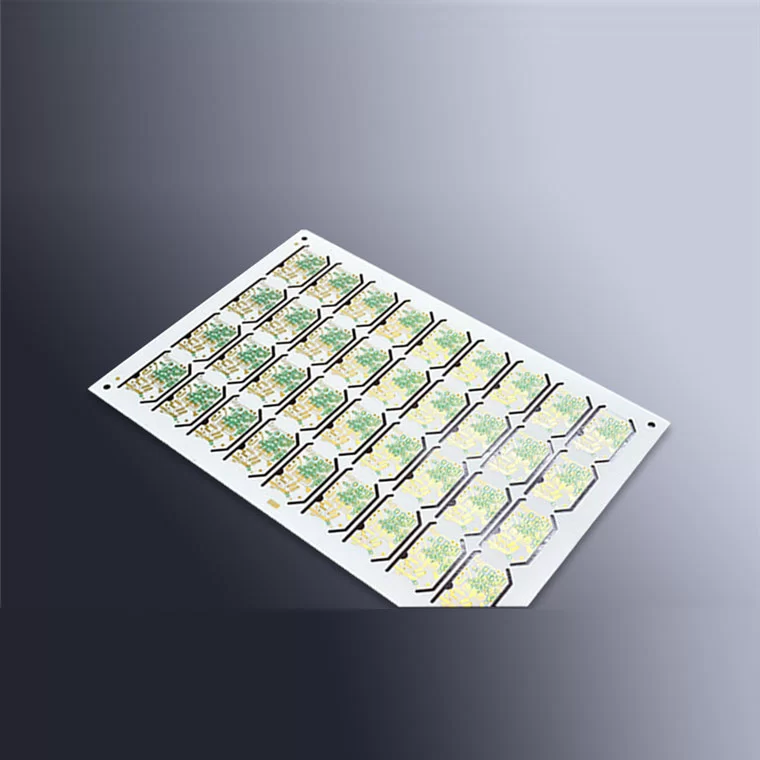

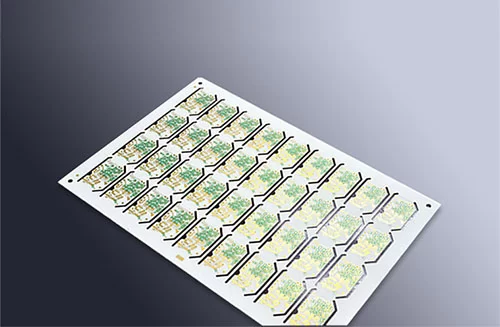

Ceramic Substrate PCBs

What's Ceramic PCB?

Ceramic PCB substrate refers to a special process board with copper foil directly bonded to the surface (single or double sides) of alumina (Al2O3) or aluminum nitride (AlN) ceramic PCB substrate at high temperatures. They are sensitive to CTE (coefficient of thermal expansion) and can withstand higher temperatures. The manufactured ultra-thin composite substrate has excellent electrical insulation, high thermal conductivity, excellent solderability and high adhesion strength, and can etch various patterns, so it has great current carrying capacity.

Benefits

High Thermal Conductivity

Compared with traditional PCB materials, FR4 ceramic PCBs (ceramic substrate PCBs) offer excellent thermal conductivity, thanks to their aluminum-based substrates (aluminum oxide or aluminum nitride).

Excellent Electrical Insulation

Ceramic core PCBs provide superior electrical insulation—critical for preventing short circuits and maintaining signal integrity, making them suitable for high-voltage or high-frequency circuits.

- Chemical Resistance & Environmental DurabilityCeramic PCBs boast strong resistance to chemicals, moisture, and other environmental elements. This durability makes them ideal for applications in harsh conditions, including outdoor equipment, chemical processing industries, and aerospace.

Are you onthe lookout for a good memory foam mattress that combines comfort and quality?

Memory modules, e.g. RAM

Photovoltaic panel

LED lamp PCB

Aerospace and aeronautics

Biological ceramic material

Metal industry

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.