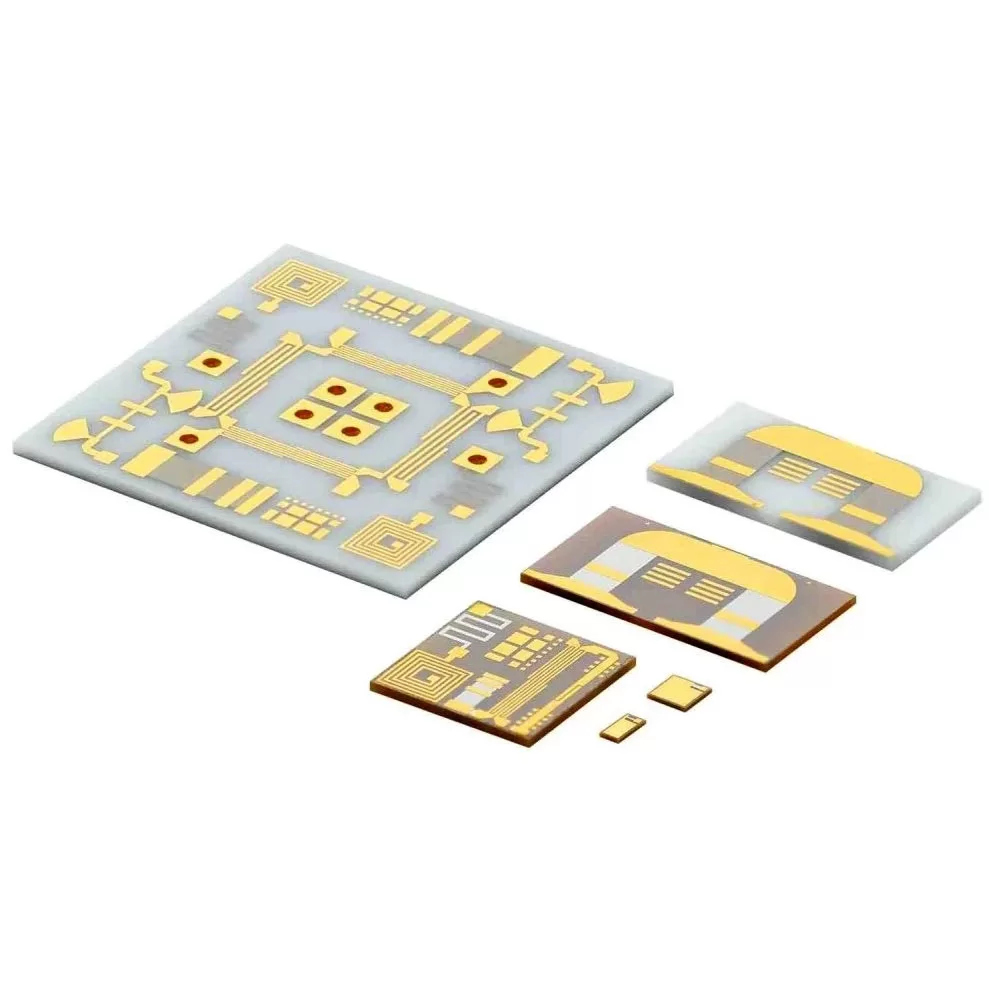

Alumina Ceramic PCB

About Alumina ceramic PCB

Alumina ceramic PCB substrate is the most commonly used substrate material in electronic industry, because of its high strength and chemical stability compared with most other oxide ceramics in mechanical, thermal and electrical properties, and abundant raw materials, it is suitable for various technical manufacturing and different shapes. The alumina substrate can be customized in three dimensions.

Application

1. Power Electronics

-Energy Vehicles: Used in onboard power modules (OBCs), motor controllers, DC-DC converters, and other applications, they withstand high voltage, high current, and high-temperature environments.

-Industrial Power Supplies: Suitable for power devices such as IGBTs and MOSFETs in high-frequency switching power supplies, inverters, and UPS power supplies, improving power supply stability and lifespan.

-Power Equipment: Used in rectifiers and transformers in smart grids, as well as power conversion modules for renewable energy power generation (photovoltaic and wind power).

- 2. LED Lighting-Outdoor Lighting: LED streetlights and tunnel lights, for example, operate in high-temperature environments for extended periods of time. Alumina ceramics can quickly dissipate heat from the lamp beads. Industrial lighting: Such as high-power spotlights in workshops and stage lighting, meeting the centralized heat dissipation requirements of dense light sources.-Specialty lighting: Such as cold light sources for medical use and LED modules for automotive headlights, balancing heat dissipation and miniaturization.

- 3. Sensors and Detection-Automotive sensors: Such as engine temperature sensors and exhaust system sensors, withstanding the high temperatures and vibrations within the engine compartment.-Industrial sensors: Such as high-temperature pressure sensors and flow sensors, used in high-temperature production scenarios such as metallurgy and chemical engineering.-Environmental monitoring sensors: Such as gas sensors and infrared sensors, maintaining insulation and structural stability in complex environments.

- 4. Medical and Aerospace-Medical equipment: Used in the core circuits of high-frequency electrosurgical units, ultrasound diagnostic equipment, and laser therapy equipment, ensuring both insulation and anti-interference performance.-Aerospace: Suitable for satellite communication modules, airborne radars, and spacecraft power systems, withstanding the low temperatures, radiation, and vibrations of space.

Characteristic

'-Higher operating temperature up to 350°C (using thick film printing)

- -Low coefficient of expansion (6-8 ppm/°C)

- -Compatible with components

- -Good thermal performance (22-24 W/mK)

- -Excellent high-frequency performance

- -Smaller package size due to integration and multilayer possibilities

- -High resistance to abrasion and chemical hazards

- -Possible hermetic packaging with 0% water absorption

- -White color with excellent light reflectivity

- -Limited to no outgassing

- -Strong, rigid material

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.