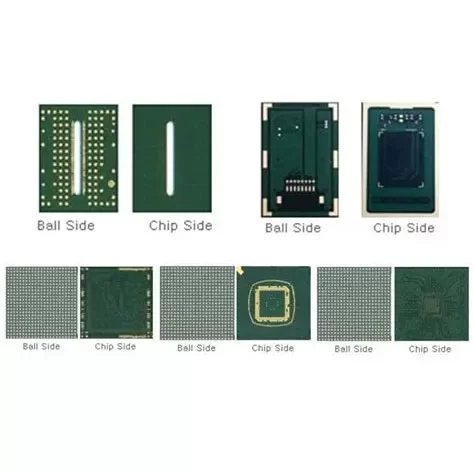

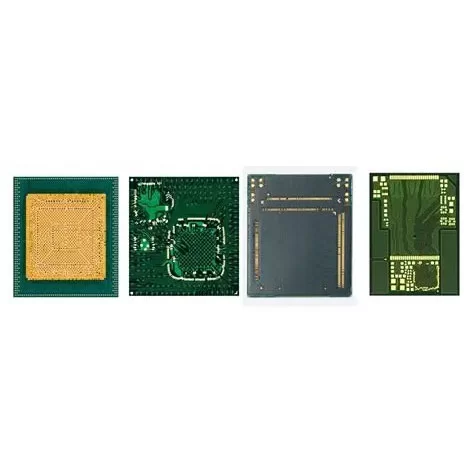

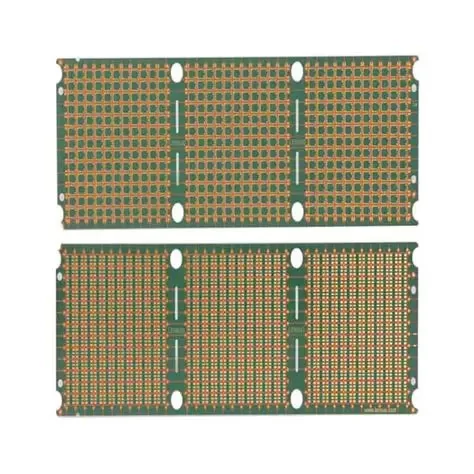

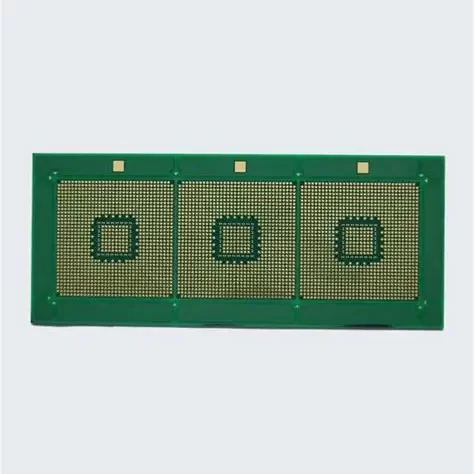

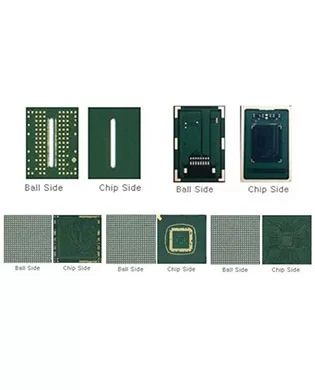

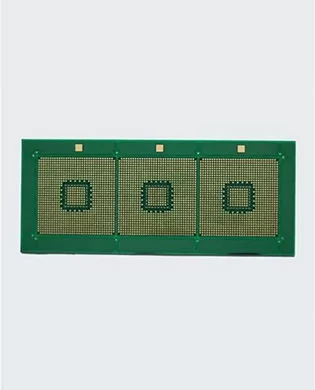

Sensor IC Substrate PCB

Data Sheet

Product Name: Sensor IC Substrate

Material: SI1OU

Minimum width/spacing:35/35um

- Surface: Immersion Gold

- PCB thickness:0.3mm

- Layer: 4Layers

- Structure: 1L-4L,1L-2L,3L-4L

- Solder mask ink: TAIYO PSR4000 AUS308

- Aperture:Laser hole 0.075mm, Mechanical hole 0.1mm

- Application: Sensor IC Substrate

Functions of Sensor IC Substrate

1. The IC substrate acts as a bridge that connects the microchip and PCB by making electrical connections.

- 2. It provides mechanical support to the chip.

- 3. IC substrate plays a key function in managing heat dissipation and preventing overheating.

- 4. The IC substrate protects the microchip from external environmental conditions.

- 5. Their small size and light weight help designers manufacture smart devices.

Application

1. Consumer Electronics: mobile phone processors, memory devices and digital cameras etc.

2. RF Technologies: The RF technologies require high frequency and high-speed transmission, e.g. 5G.

- 3. Military Industry: Drones, missiles, and aircraft etc.

- 4. Automotive Electronics: navigation modules and autonomous driving systems.

- 5. Medical Devices: pacemakers for heart patients and other diagnostic equipment.

Common Materials in IC Circuit Substrates

'-FR-4, ceramic, and organic laminates are widely used core materials. FR-4 is favored for its excellent mechanical and thermal properties, while ceramic substrates are used in high-frequency and high-power applications due to their excellent thermal conductivity and electrical insulation.

-Copper is the primary conductive material used in IC substrates due to its high electrical conductivity and thermal properties. Gold and silver are also used in specific applications requiring high reliability and corrosion resistance.

-Advanced dielectric materials such as epoxy and polyimide are used to insulate the conductive layers. These materials offer excellent electrical insulation, thermal stability, and chemical resistance.

-ENIG, OSP, and immersion tin are common surface finishes that improve solderability and protect the substrate from oxidation and corrosion.

-Epoxy-based soldermasks are often used to protect circuitry and prevent solder bridges during assembly.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.