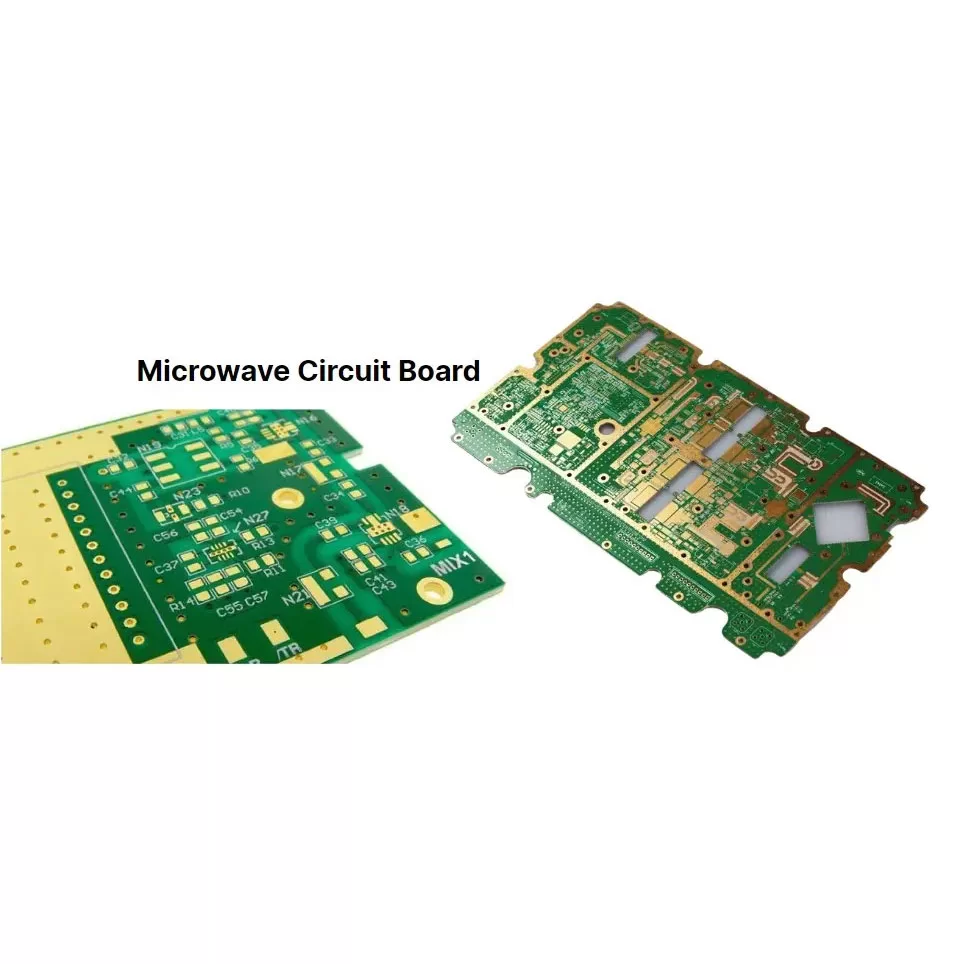

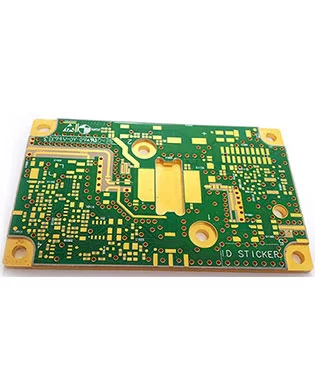

Microwave Circuit PCB

Data Sheet

Model: Microwave circuit PCB

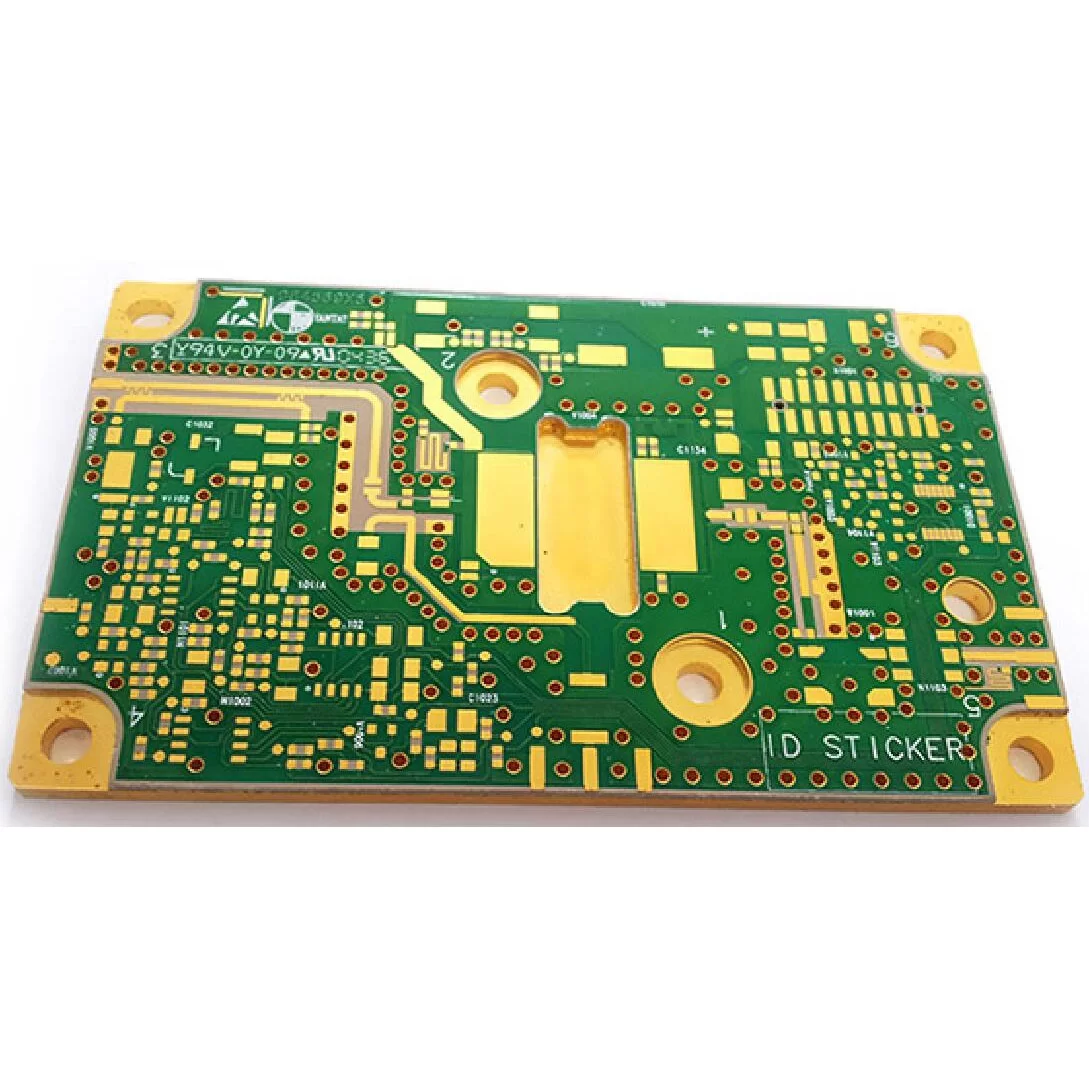

Material: Telfon,PTFE,Ceramics

- Quality standard: IPC 6012 Class2

- PCB DK:2.0-1.6

- Layers:1 Layer pcb-36 layer pcb

- Thickness:0.254mm-12mm

- Copper thickness:base copper 0.5oz/ 1oz

- Surface technology: Silver, Gold, OSP

- Special process: mixed material, stepped groove

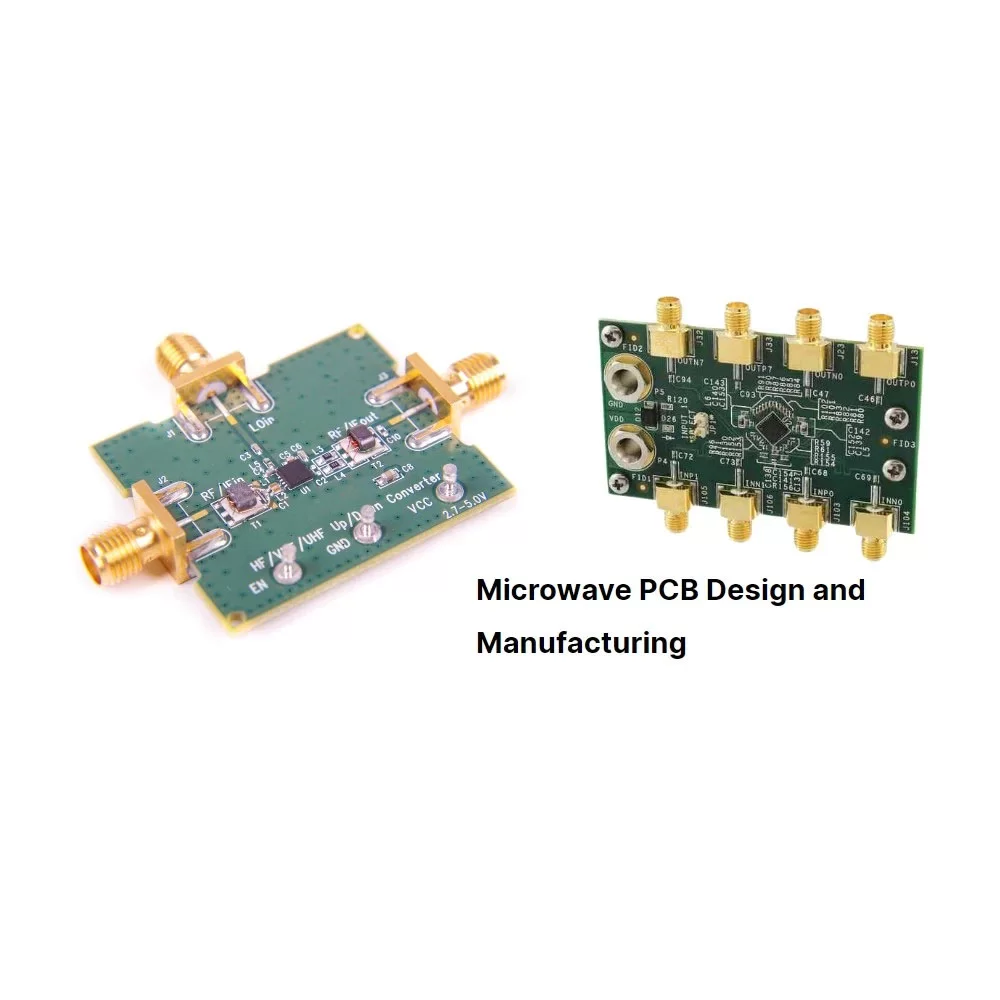

- Application: Microstrip antenna, Radar PCB

Microwave PCB is a specialized printed circuit board designed to handle high-frequency signals, typically ranging from 50 MHz to above 2 GHz. Their focus on low dielectric loss, impedance control, and precise signal transmission. They often utilize advanced materials like PTFE, ceramics, or hybrid laminates that combine FR-4 and PTFE layers to achieve superior performance.

These boards are essential in applications where signal integrity is critical, such as telecommunications, aerospace, and medical devices.

Advantages

Microwave PCBs offer numerous advantages that make them an indispensable component of modern electronics applications. These include:

-Microwave PCBs are designed to operate efficiently at high frequencies, ensuring minimal signal loss, low distortion, and reliable performance.

-The precision design and advanced materials used in microwave PCBs ensure accurate signal transmission and processing, making them an ideal choice for applications requiring high precision and reliability.

- -Strict manufacturing processes and high-quality materials ensure that microwave PCBs meet stringent performance and reliability standards, reducing the risk of failure in real-world applications.

- -Microwave PCBs can be used in a wide range of applications, from telecommunications to radar systems and medical devices, making them versatile and adaptable to diverse industry needs.

- -The use of standardized manufacturing processes and materials in microwave PCBs enables cost-effective production, making them an economical choice for high-volume electronics applications.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.