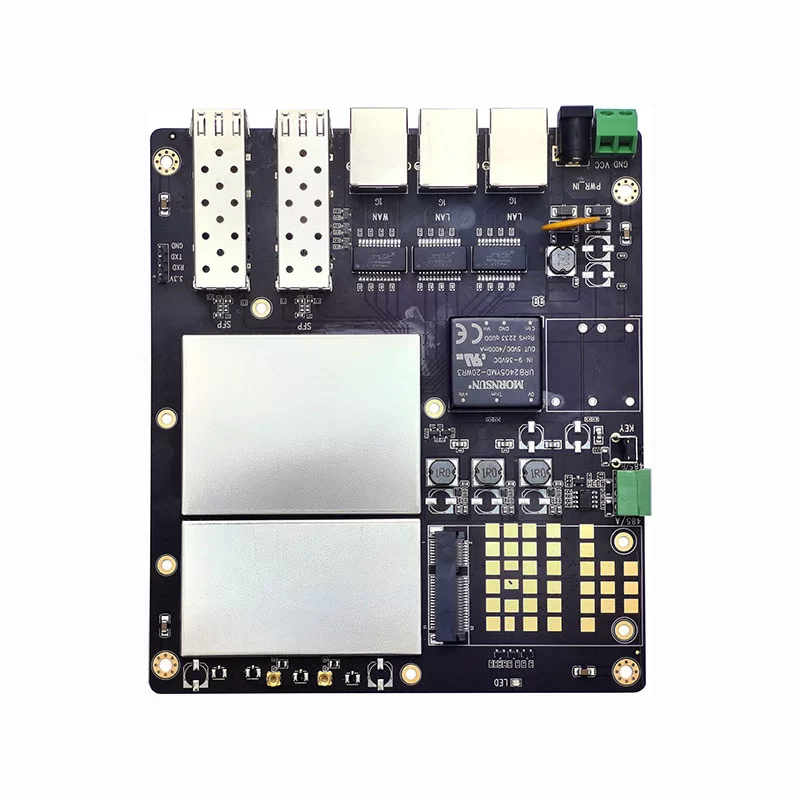

Wifi Router Mainboard PCB Assembly

Importance of Wifi Router Mainboard PCB Assembly

Hardware Platform: All router functions rely on the PCBA board as the hardware platform.

Performance Determinants: The types of components selected, the design layout, and the manufacturing process on the PCBA board directly determine the router's processing performance, network throughput, wireless coverage and strength, stability, power consumption, and other key indicators.

Core Cost: The PCBA board is typically the largest component in the router's BOM (Bill of Materials) cost.

Role of Wifi Router Mainboard PCB Assembly

The PCB in a router manages data routing between a local network (LAN) and external networks (WAN or internet). It integrates communication chips, antennas, and power management circuits to ensure stable data transmission, which is vital for ems companies involved in pcb assembly services.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.