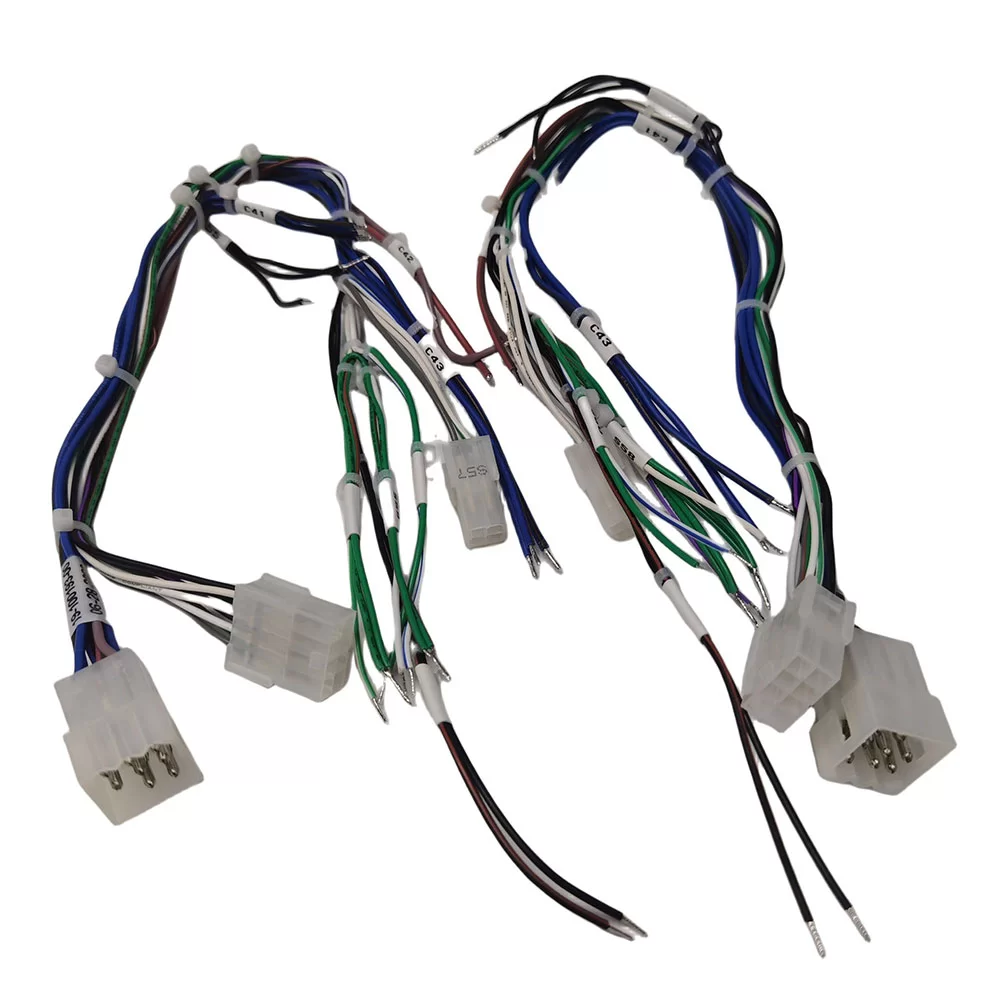

Automotive Wire Harness

Types of car wiring harness

There are 11 types of automobile wiring harnesses: Engine 2nd wiring harness, Engine room wiring harness, Main wiring harness, Left front door wiring harness, Body wiring harness, Left rear door wiring harness, Taillight wiring harness, Interior light wiring harness, Right rear door wiring harness, Right front door wiring harness, and E.F.I. wiring harness. The vehicle’s LHD and RHD are different since the wiring harness circuit position is a signal. Please refer to the LHD and RHD pictures below to distinguish between them precisely.

Application

1.Passenger cars and commercial vehicles

- 2.Electric vehicles (EVs) and hybrid cars

- 3.Heavy-duty trucks and off-road machinery

- 4.Navigation, lighting, dashboard, and control systems

Automotive wire harness has very strict requirements on materials

1. The ambient temperature around the engine is high, and there are many corrosive gases and liquids. Therefore, the wires of the engine wiring harness must use high-temperature resistant, oil-resistant, vibration-resistant, and friction-resistant wires.

2. The wires on the automatic transmission use wires that are resistant to hydraulic oil, high temperature, and have good temperature stability.

- 3. The wires of the wiring harness on the luggage compartment cover should maintain their elasticity at low temperature, so cold elastic wires should be selected for normal operation.

- 4. Weak signal sensors should use shielded wires.

- 5. The ABS wire harness assembly uses high temperature resistance of 150-200°C, hard outer protective insulation layer, wear resistance, and the wire core is combined into a stranded wire.

- 6. The wires used for power lines such as starter alternator output wires and battery wires are special wires that can withstand large currents, have good heat dissipation performance of the insulation layer, and reduce voltage.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.