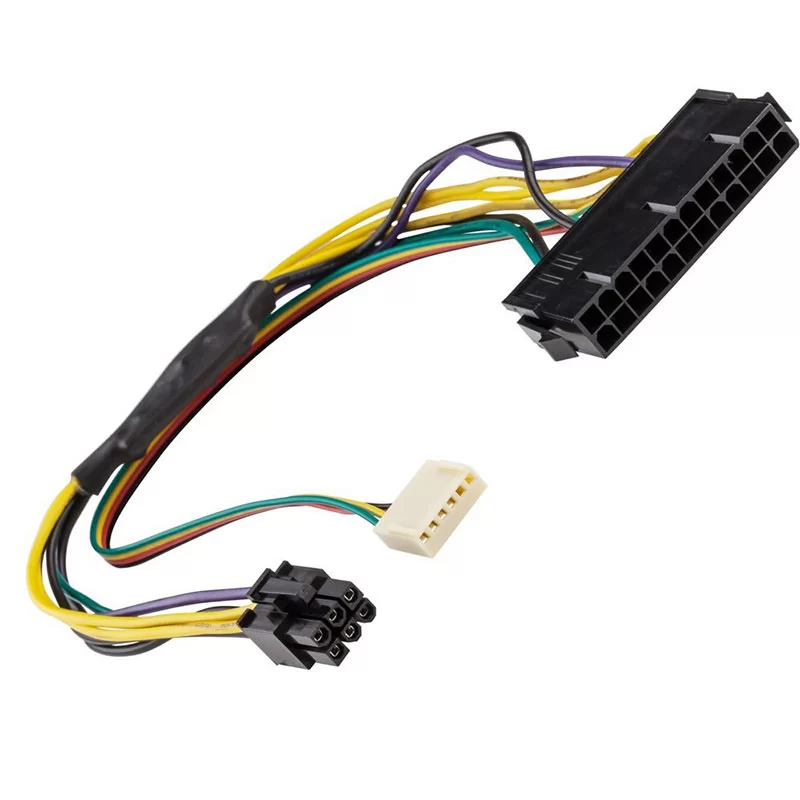

Overmolded Cable Assembly

What are Overmolded Cable Assemblies?

Custom overmolded cable assemblies are complete assemblies that seamlessly combine the various parts of the cable and connector to meet customer needs. The overmolding process involves injecting molten material into a mold cavity that, when cooled, conforms to the desired shape. In almost every sector and application, custom molded cable assemblies are widely used while being able to resist the rigors of the most challenging settings.

Differences between Molded Cables and Overmolded Cables

Molded cables and overmolded cables are both types of cable assemblies that feature a connector or termination at one or both ends of the cable. The key difference between the two lies in the manufacturing process and the resulting design.

A molded cable assembly is created by molding the cable and connector into one solid piece, typically using a hard plastic or rubber material. This process results in a cable assembly that is very durable and resistant to damage from external factors like moisture, dust, and physical stress. Molded cable assemblies are commonly used in applications where the cable will be exposed to harsh environments or frequent use, such as in industrial or military settings.

On the other hand, an overmolded cable assembly is created by molding a soft plastic or rubber material over an existing cable and connector. The overmold provides additional protection to the cable and connector, making the assembly more resistant to bending, twisting, and other forms of stress. Overmolded cable assemblies are often used in applications where flexibility is important, such as in robotics or medical devices.

Benefits of Overmolded Cable Assemblies

1. Increasing the flexural strength, especially where the cable exits. This area is going to bear the brunt of movement in most situations so additional strength is required to make sure the connection remains reliable.

- 2. Increasing the level of protection overall against outside forces like temperature swings, moisture, rubbing, impacting, and shocking.Enhancing the physical security for the cable assembly.

- 3. Increasing the strain relief provided, as well as the pull strength.

- 4. Creating a seal for the cable assembly connection that can be completely water-tight, resist moisture, resist oil, and provide some other resistance based on the needs of the application.

- 5. Helping to improve the aesthetics of the assembly and making visual cues that aid with installation of the assembly into its intended system.

Overmolded Cable Assembly Materials:

> Polyethylene (PE)

> Polypropylene (PP)

- > Polyvinyl Chloride (PVC)

- > Thermoplastic Polyurethane (TPU)

- > Acrylonitrile Butadiene Styrene (ABS)

Customization Options for Overmolded Cable Assemblies

1. Changing up colors to meet the client needs, make it easier to install, more aesthetically-pleasing, etc.

- 2. Incorporating corporate logos or names.

- 3. Including attachment hardware like flanges.

- 4. Changing the angle of the exit point whether that’s straight, at a right angle, or just about any other customization required.

- 5. Using any one of a number of different materials like PVC and TPU (more on these later).

- 6. Utilizing different processes like low pressure and injection molding.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.