Cable Coiling

What is Cable Coiling?

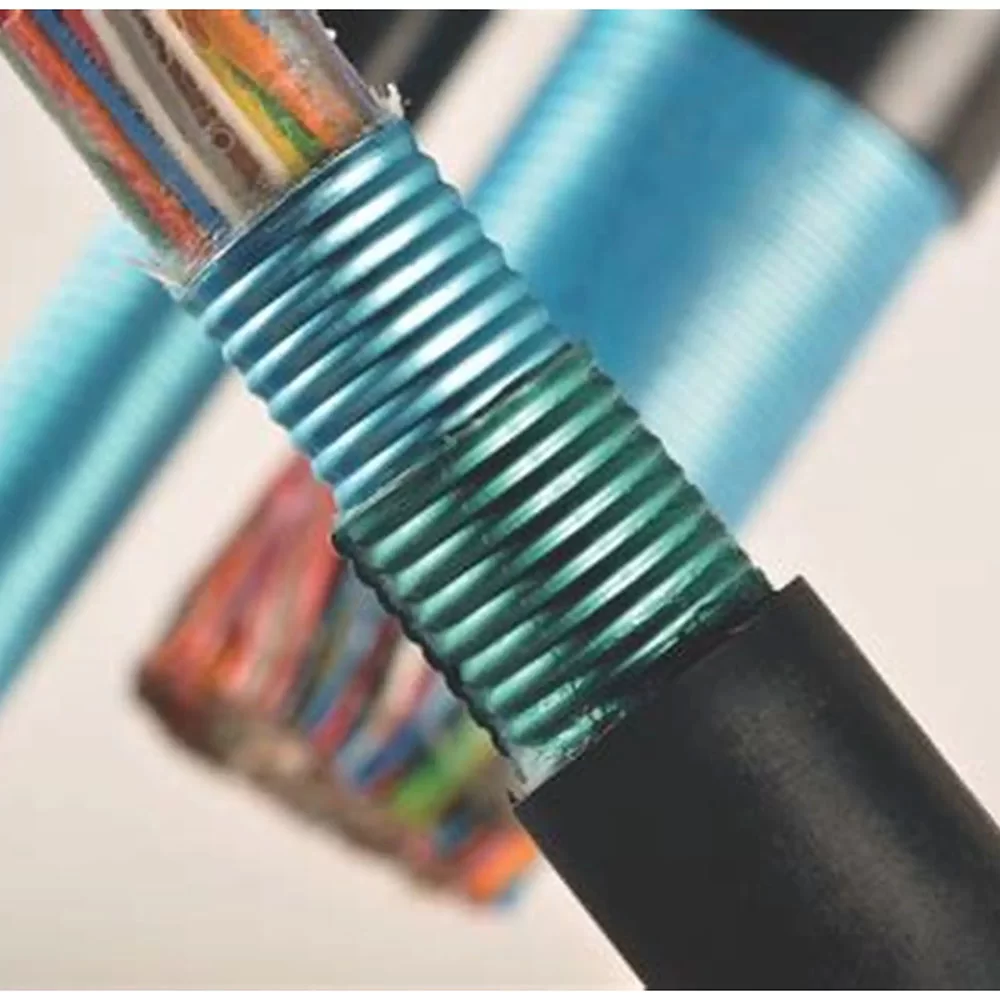

Cable coiling is the process of giving mechanical cables a spring-like shape for simple functionality. Coiled cables stretch beyond at-rest states while still retracting if needed.

Cable coiling keeps the inside components of a cable safe with several practical benefits.

Strands and Coiling

Based on customer preference, the number of strands engineered into a cable correlates to how strong it is. The thicker the cable and coil, the stronger and more durable the product will be during application. After cutting back on coil fatigue by incorporating more strands, products can hold heavier loads and more tension.

Similar to other mechanical cable coatings, the diameter of coil strands alters the physical characteristics of products. Engineering coiled cables with larger diameters strengthens the cable and makes it less prone to abrasion, damage and crushing.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.