High Speed PCB

Data Sheet

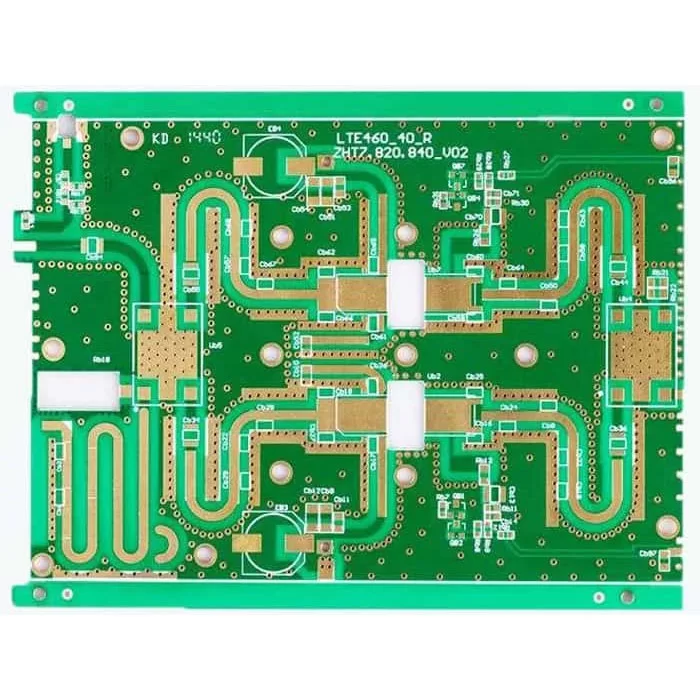

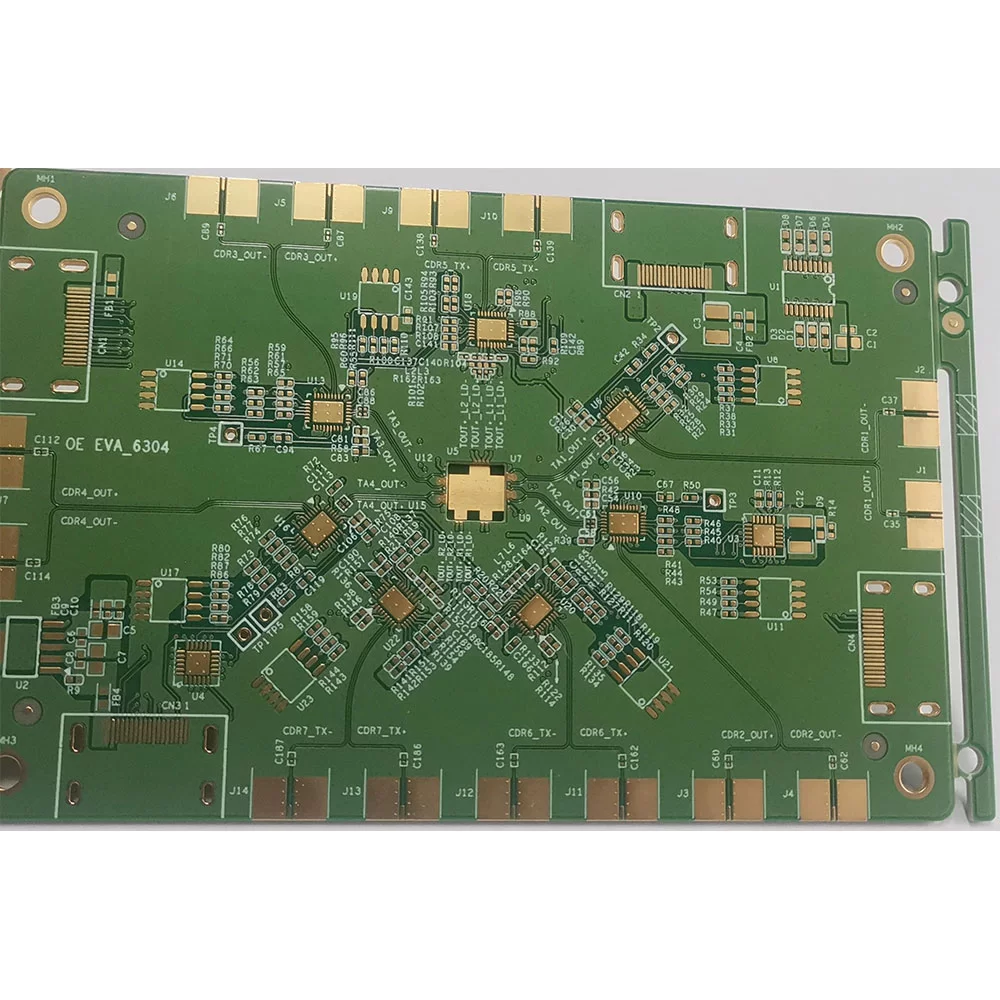

Model: High speed PCB

- Layer: 8 Layer PCB

- Material: TUC/TU872LK

- Finished Thickness: 1.0mm

- Copper Thickness: 0.5OZ/1OZ

- Color: Green/White

- Surface treatment: Hard Gold 3-15U

- Min Trace/ Space: 3mil/3mil

- Application: Communication backplane PCB

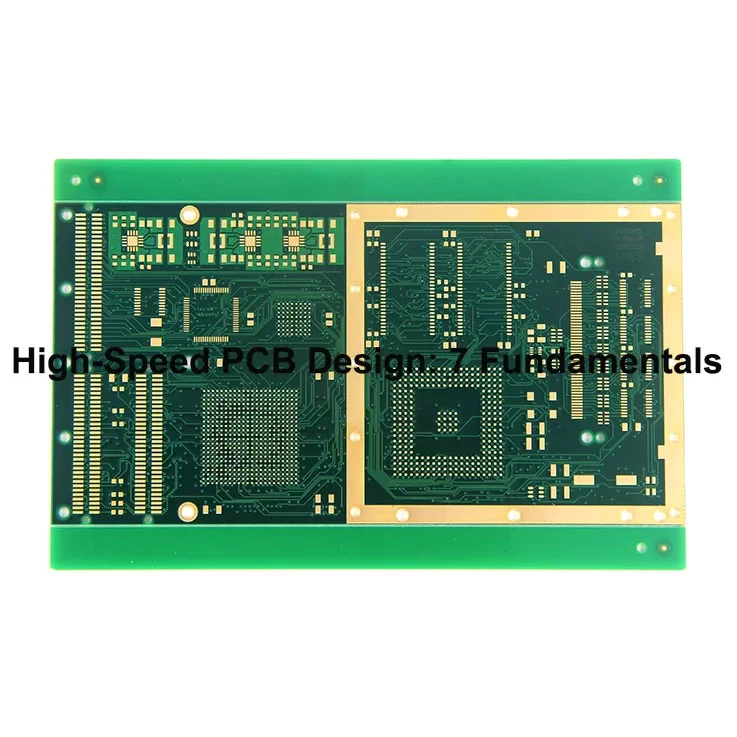

What's High-speed PCB?

High-speed PCB design is a specialized area of electronics engineering that focuses on managing fast digital signals. The core of design deals with the complexities of high-frequency signals. Unlike standard PCB design, which mainly concerns connecting components, high-speed PCB design ensures that these connections support rapid signal transmission without degradation.

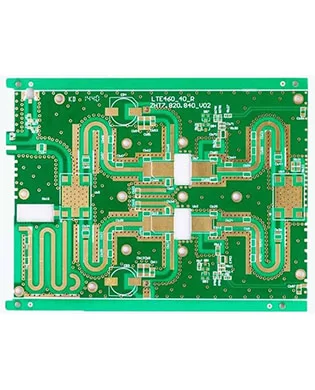

How to choose PCB material for high speed design?

1. Low loss,CAF / heat resistance and mechanical toughness (adhesion) (good reliability)

- 2.Stable Dk/ DF parameters (small variation coefficient with frequency and environment)

- 3.Small tolerance of material thickness and glue content (good impedance control)

- 4. Low copper foil surface roughness (reduce loss)

- 5. Choose glass fiber cloth with flat windows (reduce skew and loss)

What are the materials used for your high-speed PCB?

Usually FR4. The PCB board we usually refer to is the substrate. It is actually composed of copper foil and prepreg, and there are many classifications of copper foil and prepreg according to different applications.

FR4 uses epoxy resin or modified epoxy resin as the adhesive, and glass fiber cloth as a reinforcing material. As long as the material of this system is used, it can be called FR4, so FR4 is the general term for this resin system. The printed circuit board using FR4 material is currently the largest and most widely used type of printed circuit board in the world.

Applications

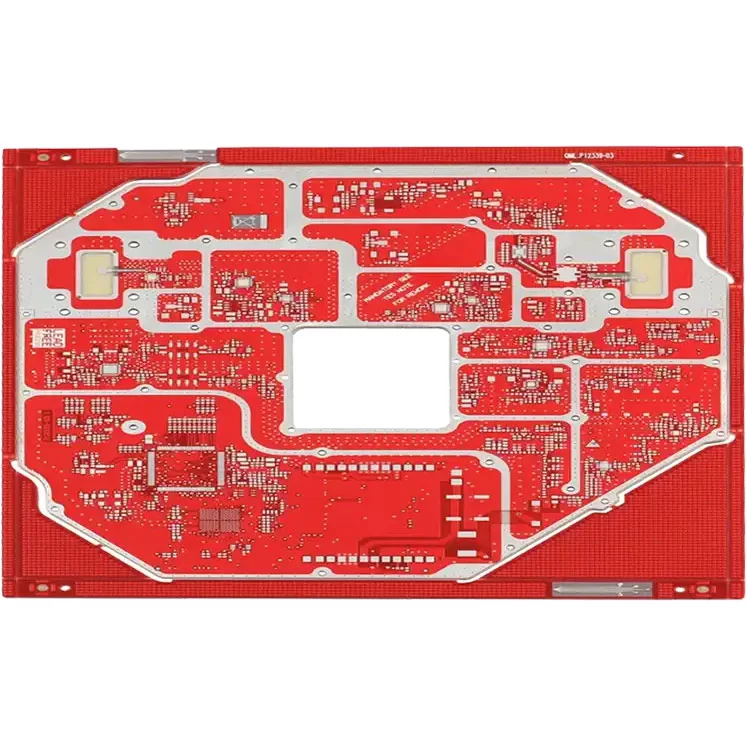

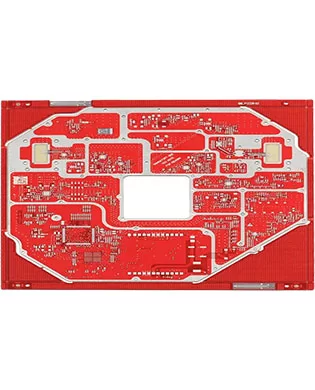

High-speed PCBs are common in almost every industry that we interact with in our daily lives, from the bank on the corner to the device and infrastructure you’re using to read this article — and that goes double for anyone reading this on a mobile device.

Some of the applications and industries we’ve worked with on high-speed digital PCBs include:

Network communications for signal integrity verification

- Small-factor layout and design for elements such as radios with a high need for impedance control

- Consumer-facing installed electronics, such as ATMs, which need to be maintained with the latest standards, have high volumes and need a short time-to-market

- High-speed digital test boards for various signals, including tests for RF signal roll-off

- Medical equipment that requires high-speed, extremely dense but low-cost individual PCBs

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.