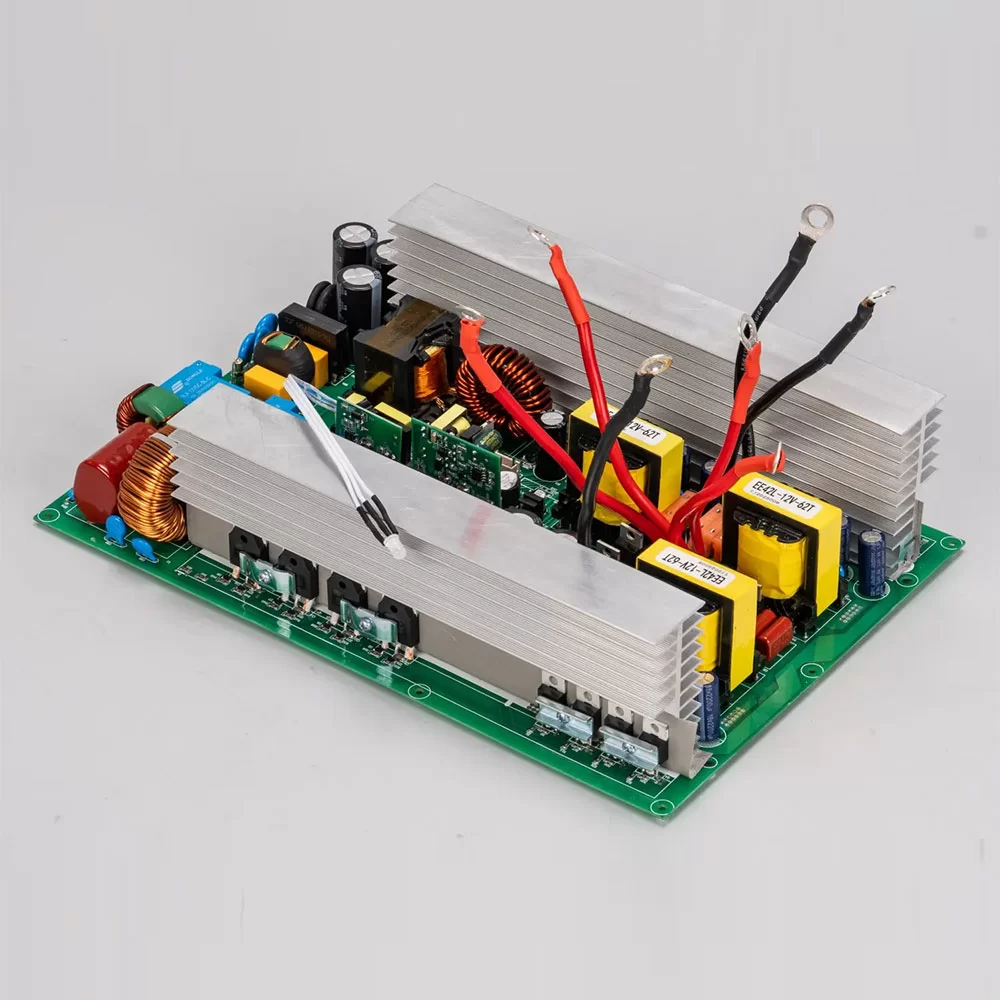

1. Features: Highly reliable and safe, with high power handling and good heat dissipation.

2. Applications: Solar photovoltaic systems, wind power systems, energy storage systems, electric vehicle charging stations, and smart grids.

3. Selling Points: Uses high-quality electronic components and advanced processes, with optimized heat dissipation and high power density assembly processes, and meets energy industry standards.

4. Processes: AOI test, FT test, ICT test, BGA technic, selective wave soldering, SMT, DIP, wave soldering, reflow soldering

5. Customization: customization according to customers' design files.

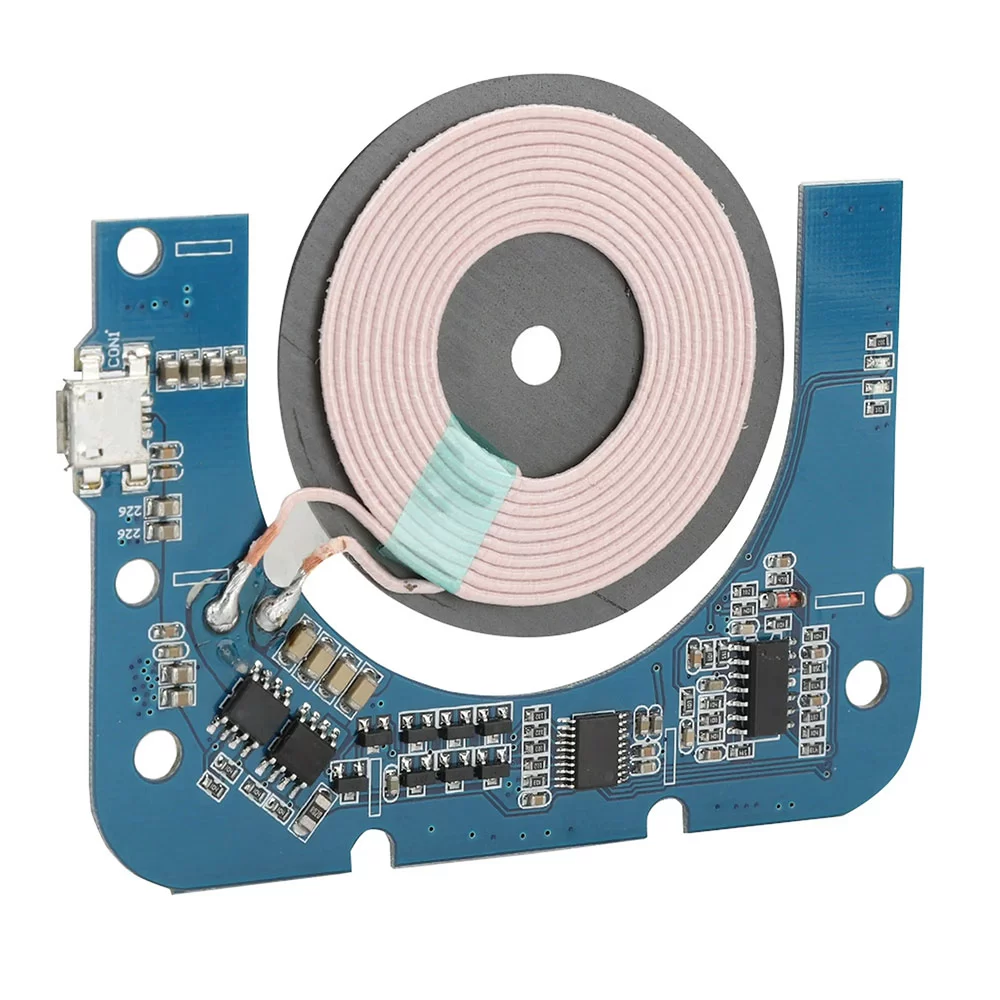

The Robot Wireless Charging Module PCBA (Printed Circuit Board Assembly) plays a critical role in determining how fast and efficiently a device charges wirelessly.

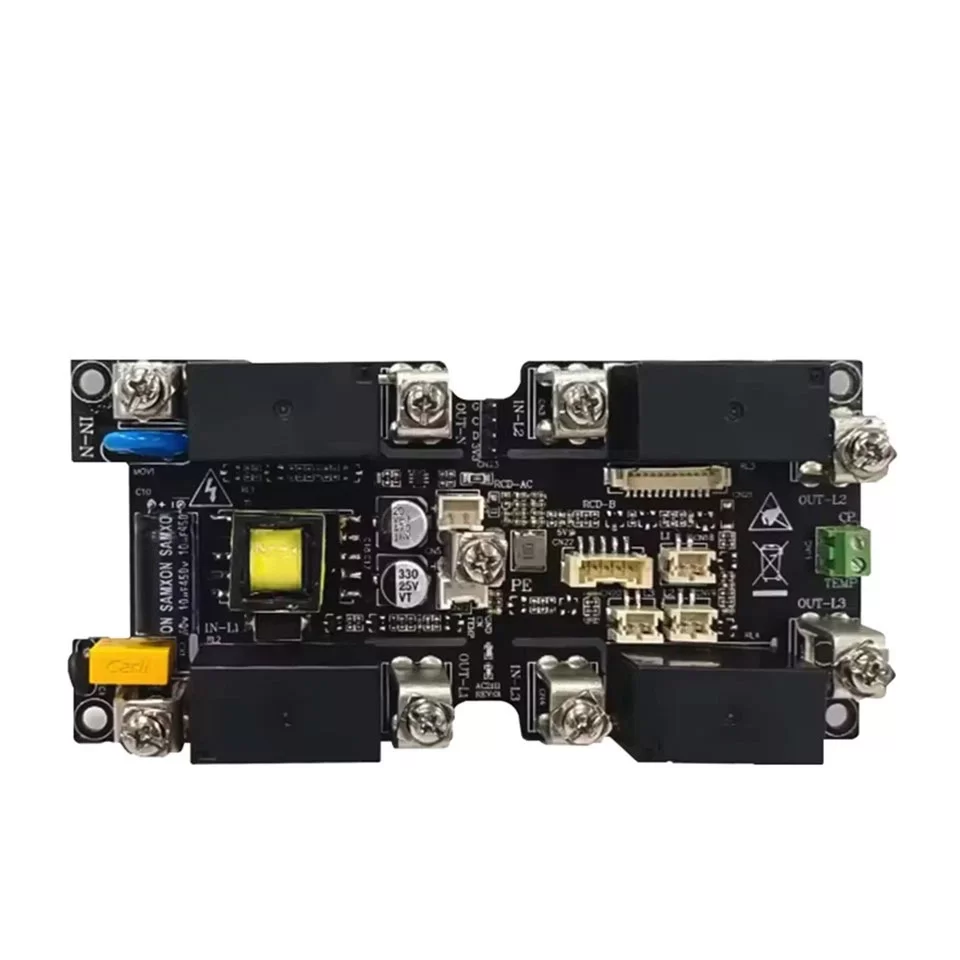

PCBs are critical in EV technology, employed in powertrains, battery management systems, onboard chargers, and vehicle control units.

Solar PCBs are the backbone of solar energy systems, controlling everything from power conversion to energy storage.

The main theme behind designing and manufacturing New energy PCBA is maximizing energy efficiency, which is one of the prime requirements for devices that use high power.