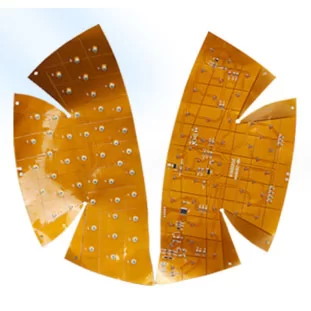

1. Features: Thin, flexible, bendable, small in size, and light in weight, with good electrical performance.

2. Applications: Smartphones, tablet PCs, wearable devices, automotive electronics like turn signal, etc.

3. Selling Points: Uses advanced flexible circuit board manufacturing and assembly technologies, adapts to complex spatial structures, and has strict quality control and testing procedures.

4. Processes: Special FPC manufacturing processes such as laser cutting, automatic stiffener machine, hybrid laminator etc. Dedicated soft board assembly technologies like Roll to Roll (R2R).

5. Customization: customization according to customers' design files.

Board Type: Flexible Board

Layers: Multilayer

Base material: PI

Solder mask: Yellow coverlay

Silk screen: No

Surface treatment: ENIG

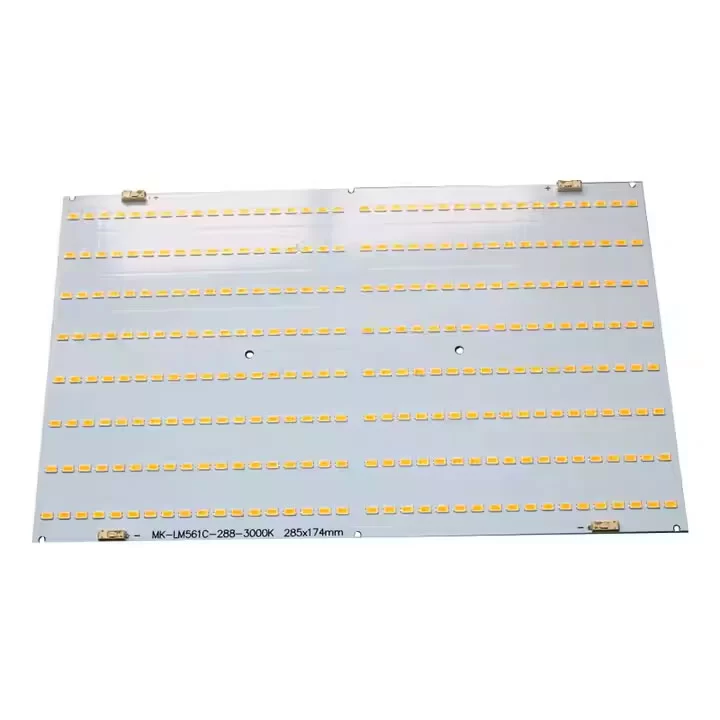

PCB Type: FPC ( flexible PCB)

Layer: Double layer

Base material: Alumium base

Solder mask: White

Silk screen: Black

Surface treatment: Lead-free HASL

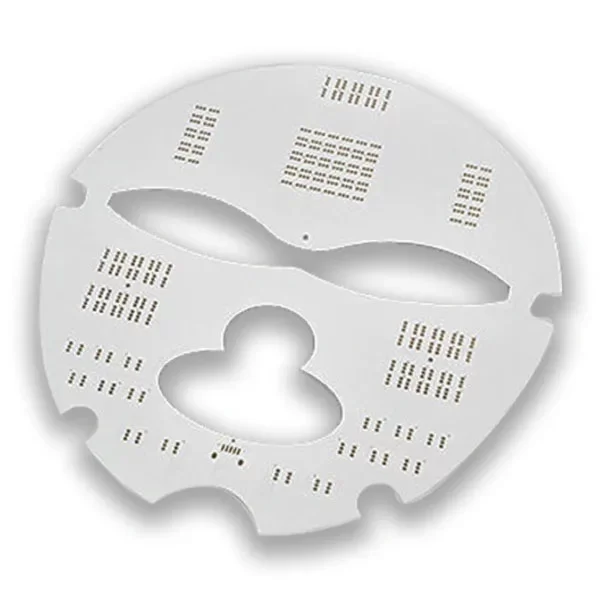

Board Type: Flexible Board

Layers: Single layer

Base material: Alumium

Solder mask: Black

Silk screen: No

Surface treatment: Lead-free HASL

Flexible PCB assembly refers to the assembly of flexible printed circuit boards. It uses a flexible substrate as the base material to structurally support electronic components and achieve electrical connections between them.