Cable potting involves encasing conductors in an epoxy, liquid, or gel within an enclosure or feedthrough housing.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

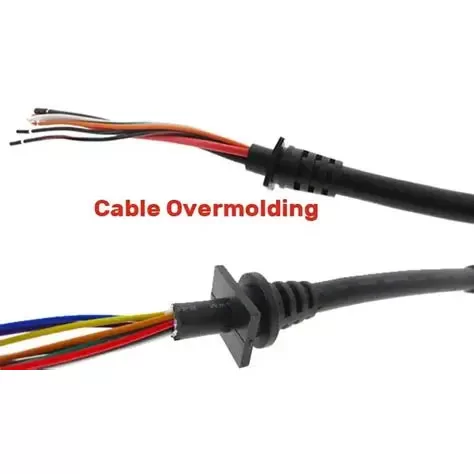

Cable overmolding is a manufacturing process that combines and seals a wire with a connector resulting in a single unified part.

Cable coiling is the process of giving mechanical cables a spring-like shape for simple functionality. Coiled cables stretch beyond at-rest states while still retracting if needed.

To facilitate your wire and cable installation, we can strip your wire for you.

The cable & wire harness assembly manufacturing process includes wire cutting, insulation stripping, wire stripping, splice, twisting, tinning, soldering, inner mold shaping, wire twisting, terminal crimping, sleeving, loop testing, tubing, cable tying, injecti onmolding, labeling, conduit threading, coiling, packaging, and AQL Inspection.

Optical fiber cable harness uses light wave as carrier and optical fiber as transmission medium.

OEM cables play a crucial role in connectivity solutions across various industries.

Many types of medical equipment, diagnostic tools, and devices incorporate electronics and computerized capabilities.

Ribbon cable is a cable designed in a flat and rectangular shape and gets its name from its resemblance to a piece of ribbon. Ribbon cable assemblies terminate into an industry-standard insulation displacement contact (IDC) socket.