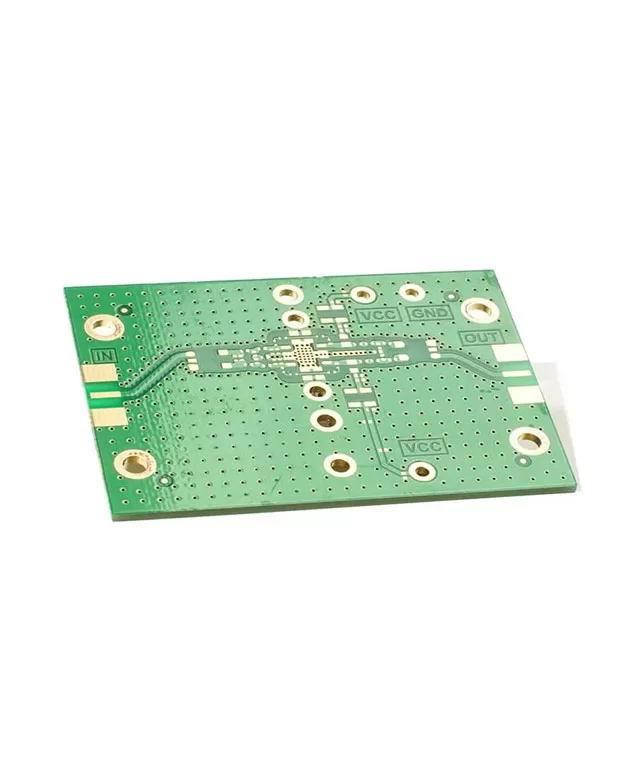

Low Loss PCB

What is Low Loss PCB?

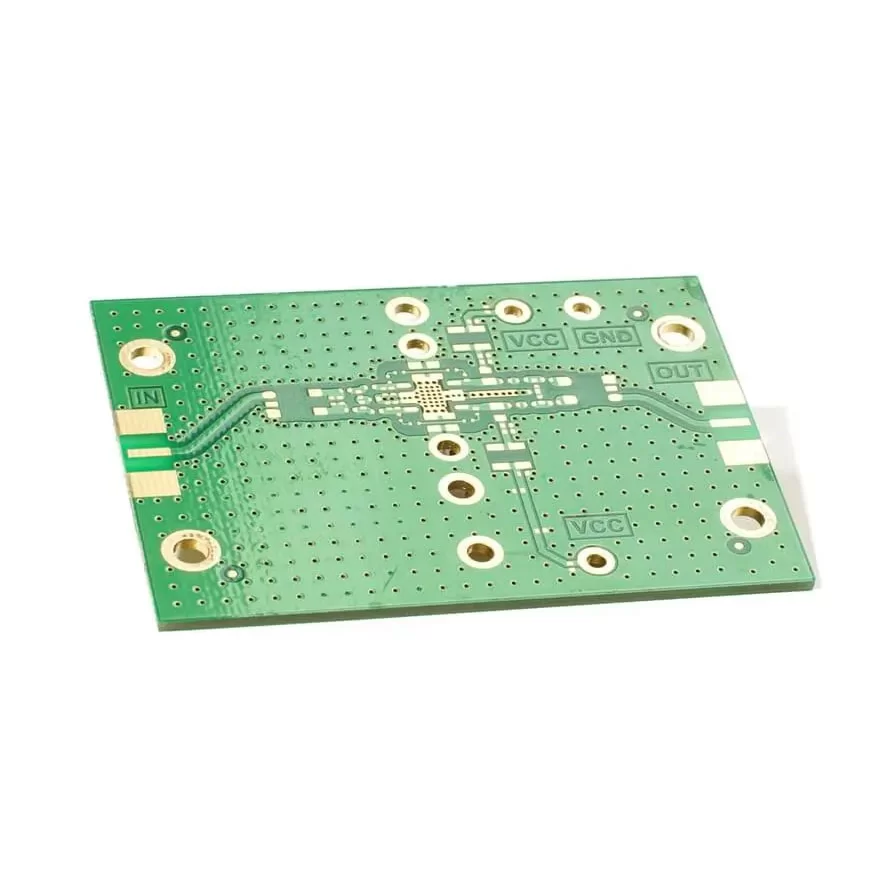

Low loss PCBs are circuit boards specially designed for reduced attenuation and losses due to the PCB's electrical, thermal, and mechanical properties. These PCBs are deployed for high-speed applications like telecommunication, medical, aerospace, automotive, RF and Microwave, defence, and handheld device applications. Low loss PCBs generally have very high physical endurance, making them reliable for longer.

The main factors affect Low Loss PCBs' performance

1. Material selection

- 2. Impedance Control

- 3. Amount of Copper in the PCB

What is the essential core of low loss PCB material?

1. Low & Stable Dielectric Constant (Dk)

Measures energy storage in an electric field. A low, uniform Dk (across wide temperatures) ensures stable impedance, low signal delay, and minimal distortion.

- 2. Low Dissipation Factor (Df)Also called loss tangent. Measures heat loss from signal energy. A low Df reduces attenuation and heat generation for high-frequency/high-speed signals.

- 3. Low Coefficient of Thermal Expansion (CTE)Measures expansion with temperature rise. A low CTE maintains PCB mechanical integrity during sudden temperature changes.

- 4. High Thermal ConductivityEnsures efficient heat dissipation. Spreads local heat evenly, preventing overheating and ensuring reliability.Material such as: Rogers RO4003C/4350B, Isola Astra MT77/100G, Panasonic Megatron 6/7, ITEQ IT998/968. Top manufacturers include Rogers, Isola, Panasonic, and ITEQ.

Advantages of Low-Loss PCBs

1.Enhanced Signal Integrity: Reduced losses also extend the usable signal distance. Minimal attenuation ensures excellent signal integrity, ideal for signal transmission.

- 2.Higher Power Efficiency: Lower attenuation and dielectric loss minimize energy waste. This saves significant energy for PCBs used in continuous data transmission/reception.

- 3.Superior Thermal Management: Excellent thermal conductivity (as noted earlier) enables even heat distribution. It prevents overheating, extends component lifespan, and boosts component performance.

- 4.Optimal High-Frequency/Speed Performance: Designed for high-frequency applications, they meet the core requirements of high signal integrity and controlled impedance.

- 5.Better EMI Shielding: Special materials reduce electromagnetic interference (EMI), making them versatile for noisy or EMI-prone environments.

- 6.Longer Lifespan & Higher Reliability: They generate less heat and are more resistant to environmental corrosion, leading to longer service life and higher reliability than standard PCBs.

Applications

Telecommunication: mobile towers, 5G and 100 Gigabit Ethernet etc.

Data Centres: servers and Network Switches.

Medical Devices: Those require very high precision signals like CT scanner or MRI machine.

Aerospace and Radar: To support high sensitivity, very high precision impedance controlled PCBs are required to maintain high precision data.

Consumer Electronics: Processing the data of smartwatches, smartphones from high-speed networks such as 5G requires Low loss PCB.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

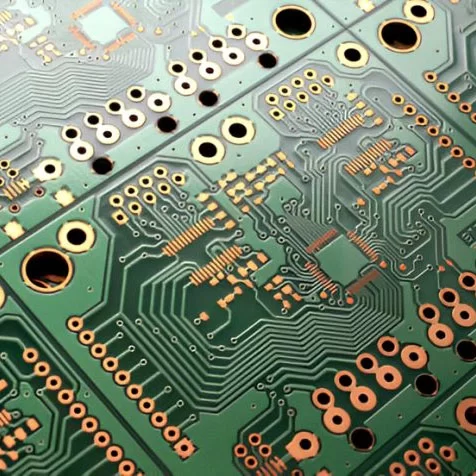

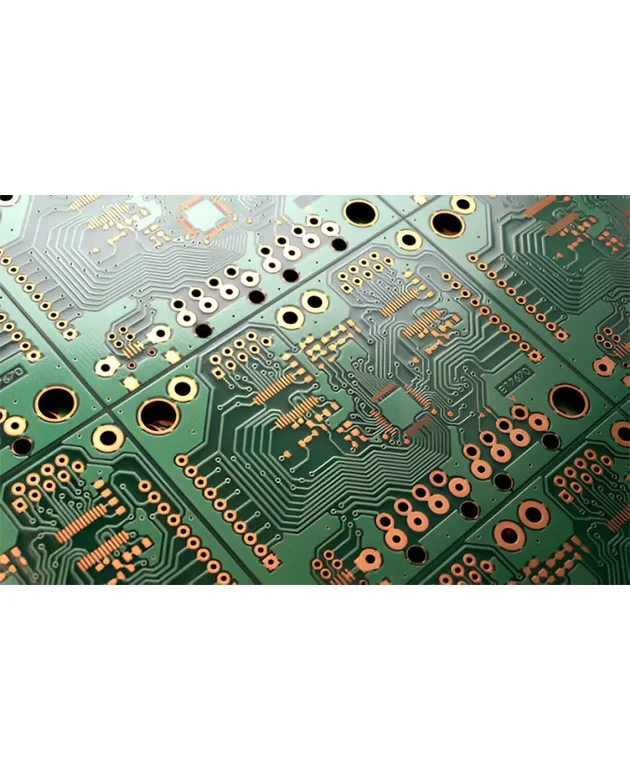

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.