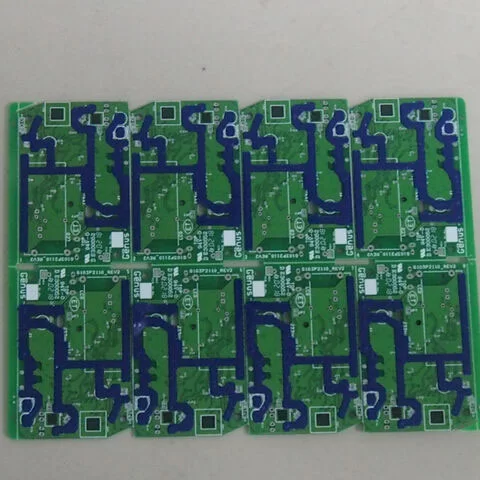

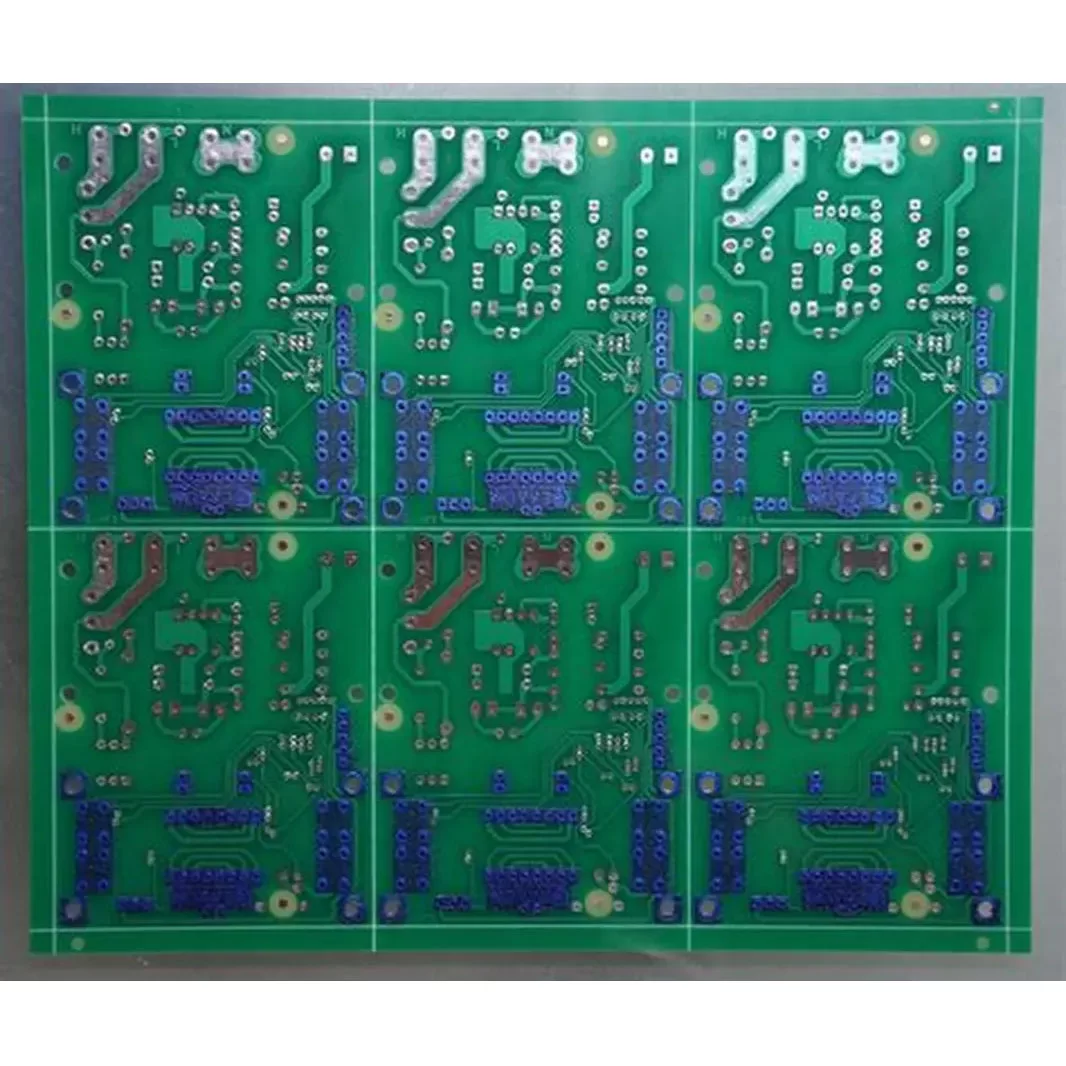

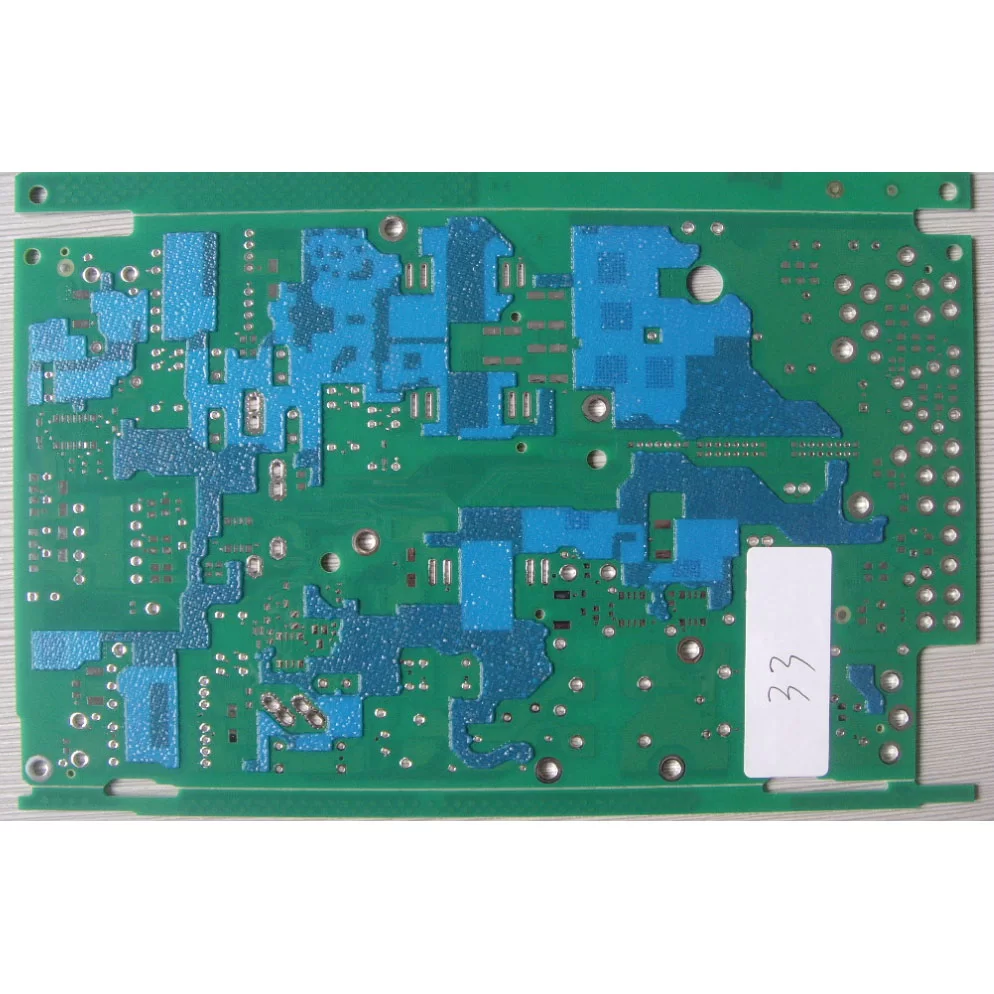

Blue Peelable Printed Circuit Boards

What is a Peelable Solder Mask?

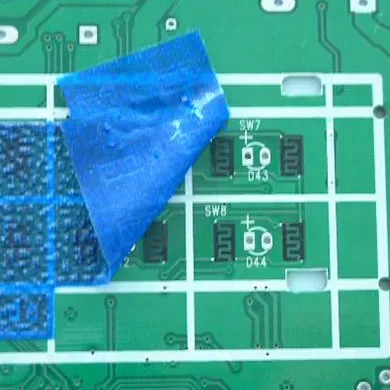

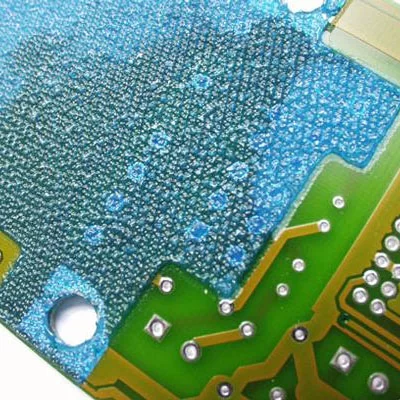

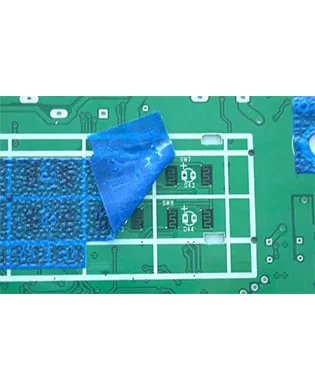

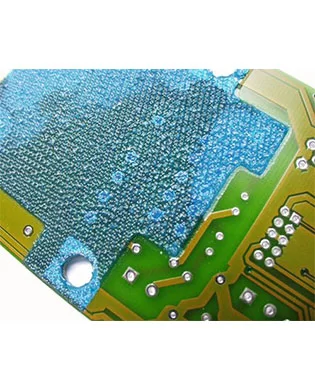

A peelable solder mask is a temporary protective coating applied to specific areas of a PCB during the manufacturing process. Unlike traditional permanent solder masks, peelable masks are designed to be easily removed after serving their protective purpose.

Key Features of Peelable Solder Masks:

Temporary protection for PCB surfaces

Easy application and removal

Resistant to high temperatures and chemicals

Prevents solder bridging and component misalignment

Leaves no residue upon removal

Peelable solder masks act as a shield, safeguarding critical areas of the PCB from damage, contamination, and unwanted solder during various stages of the assembly process.

Why Use Peelable Solder Masks in PCB Manufacturing?

The adoption of peelable solder masks in PCB manufacturing has grown significantly due to the numerous benefits they offer. Let’s explore the key advantages that make peelable solder masks an essential tool in modern electronics production.

1. Precision Protection

Peelable solder masks allow manufacturers to selectively protect specific areas of the PCB, ensuring that only intended areas are exposed to soldering processes. This precision is crucial for:

Preventing solder bridges between closely spaced components

Protecting delicate surface-mount pads

Safeguarding plated through-holes from solder ingress

2. Enhanced Quality Control

By using peelable solder masks, manufacturers can:

Reduce defects caused by excess solder

Minimize component misalignment issues

Improve overall PCB assembly quality

3. Cost-Effective Solution

Implementing peelable solder masks in the PCB assembly process can lead to significant cost savings:

Reduced rework and repair costs

Fewer scrapped boards due to assembly errors

Increased production efficiency

4. Versatility in Manufacturing Processes

Peelable solder masks are compatible with various PCB manufacturing and assembly techniques, including:

Wave soldering

Reflow soldering

Selective soldering

Hand soldering

5. Environmental Considerations

Many peelable solder mask formulations are environmentally friendly, offering:

Low volatile organic compound (VOC) emissions

Easy disposal without harmful residues

Compliance with RoHS and REACH regulations

Types of Peelable Solder Masks

Peelable solder masks come in various types, each designed to meet specific manufacturing requirements and PCB designs. Understanding these types can help in selecting the most appropriate mask for a given application.

1. Liquid Peelable Solder Masks

Liquid peelable masks are applied in a liquid form and then cured to create a protective layer.

Advantages:

Can be easily applied using screen printing or spraying techniques

Excellent conformity to PCB surface contours

Suitable for both small and large areas of coverage

Applications:

High-volume PCB production

Complex PCB layouts with varying surface topographies

2. Film-Based Peelable Solder Masks

These masks come in the form of pre-cut films that are applied to the PCB surface.

Advantages:

Quick and easy application

Uniform thickness across the protected area

Ideal for protecting large, flat areas of the PCB

Applications:

Batch production of PCBs with similar designs

Protection of entire PCB sides during double-sided assembly

3. Heat-Resistant Peelable Solder Masks

Specially formulated to withstand high temperatures encountered in soldering processes.

Advantages:

Can withstand temperatures up to 300°C or higher

Excellent protection during reflow and wave soldering

Maintains integrity through multiple heat cycles

Applications:

High-temperature soldering processes

Multi-layer PCB assembly with multiple reflow cycles

4. Chemical-Resistant Peelable Solder Masks

These masks offer protection against various chemicals used in PCB manufacturing.

Advantages:

Resistant to flux, cleaning solvents, and other PCB chemicals

Maintains integrity during chemical processes

Prevents chemical ingress into protected areas

Applications:

PCBs undergoing chemical cleaning processes

Boards exposed to harsh environmental conditions

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.