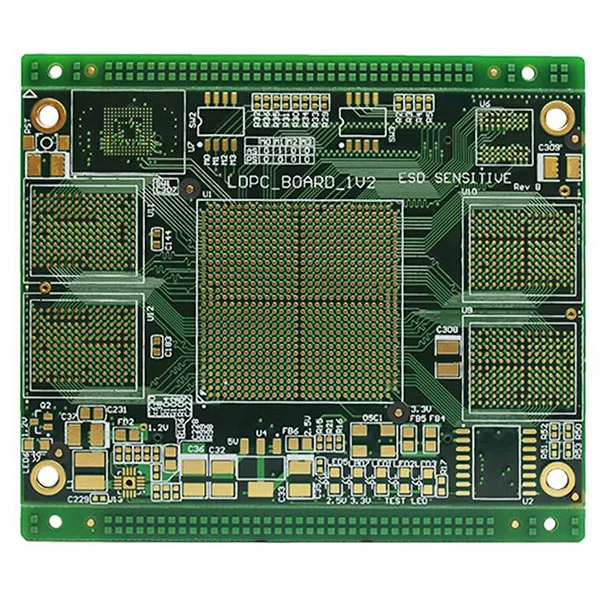

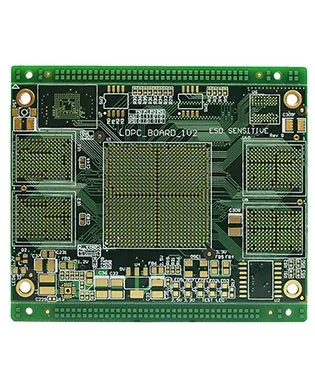

BGA PCB Manufacturing

About BGA PCB

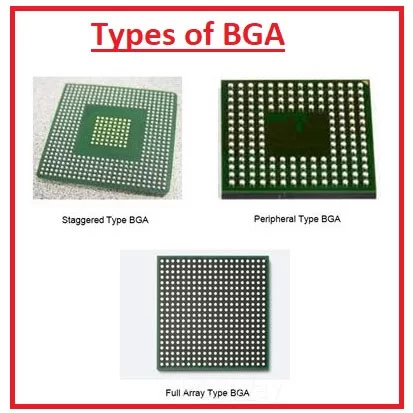

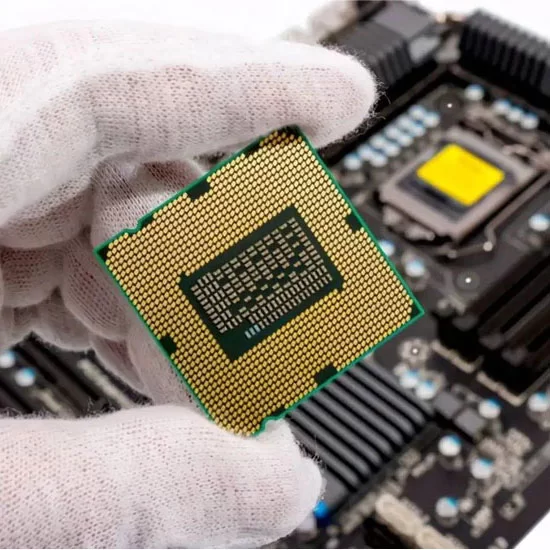

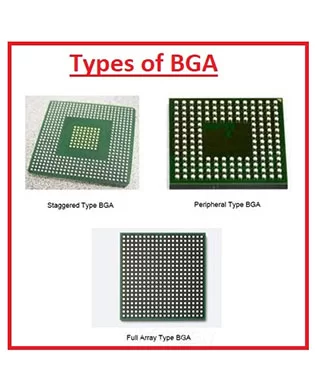

BGA PCB is a printed circuit board specifically designed for ball grid array (BGA) packaged chips. Via the array of metal solder balls on the chip’s bottom, it enables precise connection between the chip’s traditional pins and the pads on the PCB surface—effectively addressing the issues of low integration density, significant signal loss, and heat dissipation bottlenecks in electronic products.

Benefits

High-Density Integration

The solder ball array on the chip’s bottom replaces traditional pins, supporting the precision manufacturing of Fine-Pitch BGA. It meets the high integration demands of complex chips such as CPUs, GPUs, and high-end memory.

- High-Frequency & High-Temperature CompatibilityLow loss: Solder balls connect directly to PCB pads, shortening the signal transmission path and significantly reducing signal delay and interference—meeting the requirements of high-frequency scenarios like 5G and industrial control.Efficient heat dissipation: The solder ball array and the PCB’s internal copper layers form an effective heat dissipation channel, which reduces the chip’s operating temperature, prevents performance degradation due to high temperatures, and ensures long-term product stability.

High Reliability for Harsh Operating Conditions

①.Fundamental performance is controlled at the source to ensure low-loss transmission of high-frequency (HF) signals and avoid signal interference.

②.ENIG or OSP surface finishes are applied to enhance pad oxidation resistance.

③.High-density blind/buried via routing is adopted to eliminate short-circuit risks.

④.With designs and tests for vibration resistance, high/low temperature resistance, and corrosion resistance, it maintains stable operation in complex environments.

Application

Consumer Electronics

Supports an ultra-fine solder ball pitch of 0.3mm, facilitating the upgrade of foldable screens and AI terminals.

Automotive Electronics

Empowers new energy vehicles and autonomous driving, complying with the IATF 16949 standard.

Industrial & Medical

Delivers BGA PCBs for high-precision medical detection devices, and holds ISO 13485 medical system certification.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.