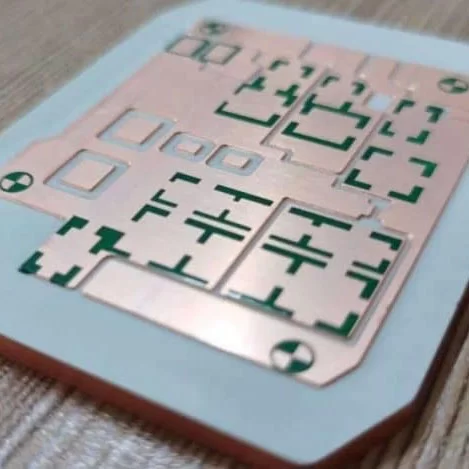

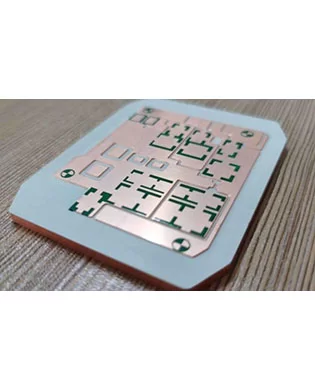

Double Layer Aluminum PCB

Data sheet

Model: 2 layer Alu PCB

Material: Aluminum PCB

Layer: 2

Color: White/Black

Finished Thickness: 1.0mm

- Copper Thickness:1OZ

- Surface Treatment: OSP

- Thermal Conductivity: 2.0w/m.k

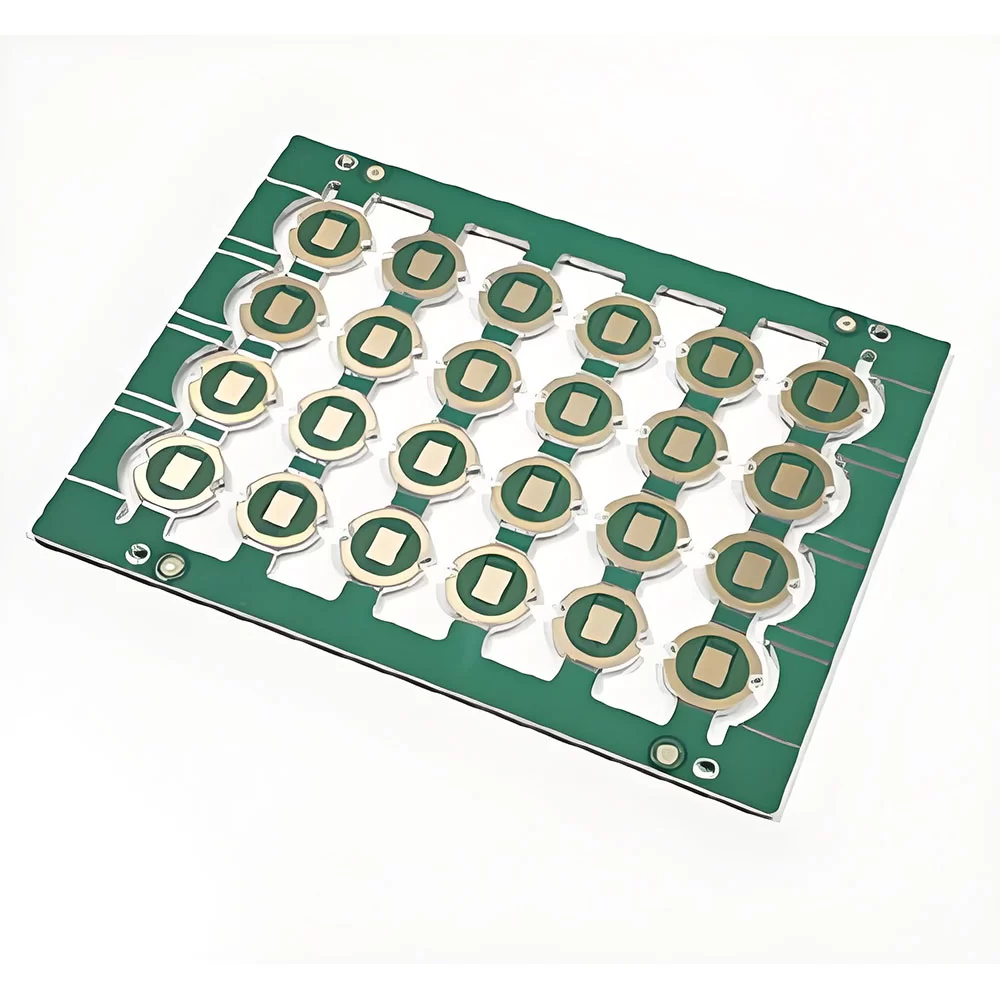

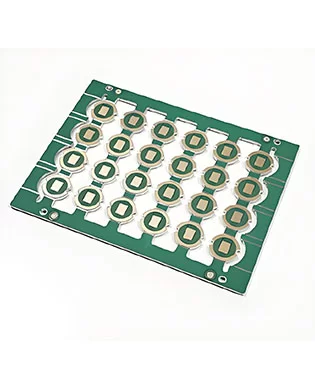

- Application: Interior LED Lighting

What is double-sided Aluminum PCB?

Double-sided aluminum substrates are widely used in electronics manufacturing. They are a metal-based copper-clad laminate with a three-layer structure consisting of an aluminum substrate, an insulating layer, and a conductive layer. Their structure and functional design are closely linked, and they play a key role in modern electronic devices.

Aluminum substrates offer high mechanical strength, providing stable physical support for the entire substrate, much like a building's foundation. Furthermore, aluminum substrates offer excellent thermal conductivity, quickly dissipating heat from the insulating layer, effectively preventing damage to electronic devices due to overheating and extending their lifespan.

Advantages of Double-sided Aluminum PCB

Double-sided aluminum PCBs offer significant advantages over standard FR-4 circuit boards: Aluminum's thermal conductivity (200W/(m·K)) is over a hundred times greater than FR-4, allowing for rapid heat transfer from components. Double-sided wiring increases circuit density, making it suitable for complex designs. The aluminum core also provides electromagnetic shielding, enhancing anti-interference capabilities. Its specialized process supports surface treatments such as LF-HASL and ENIG, making it suitable for high-temperature soldering.

Applications

5G technology,

telecommunications,

IoT and renewable energy systems.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.