FPC

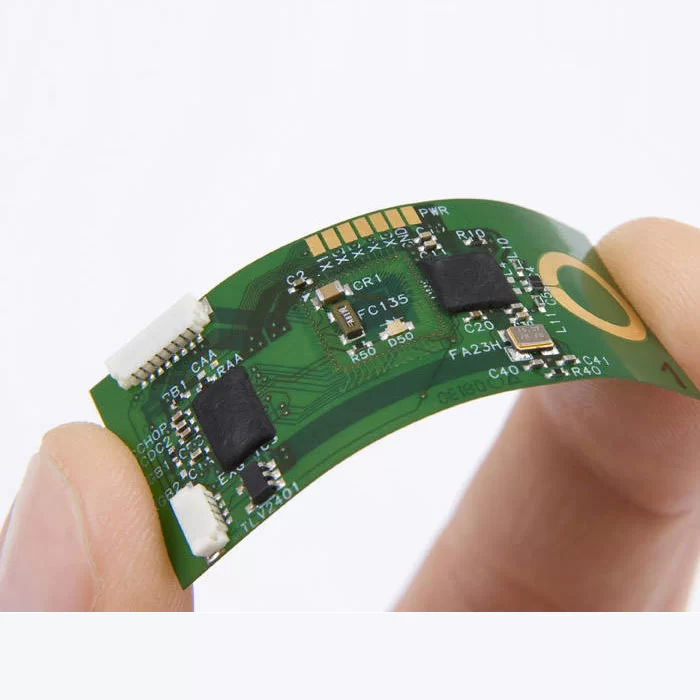

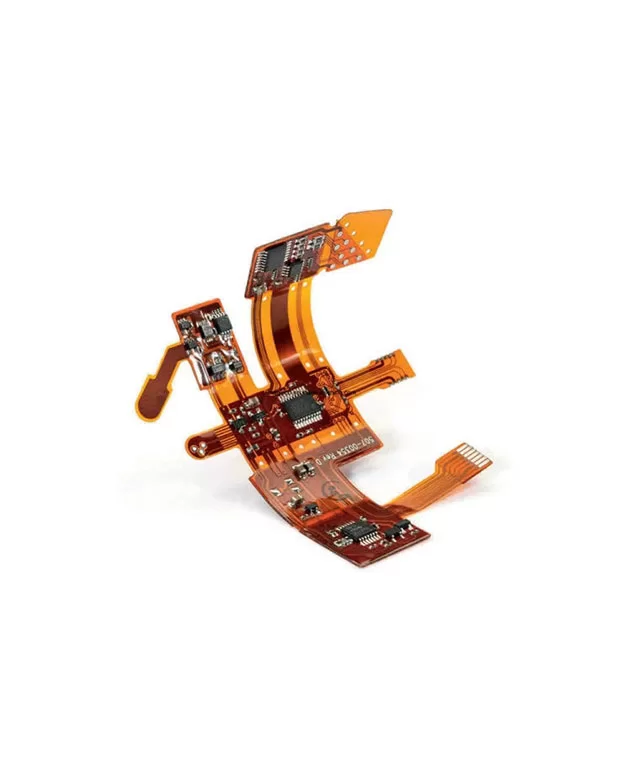

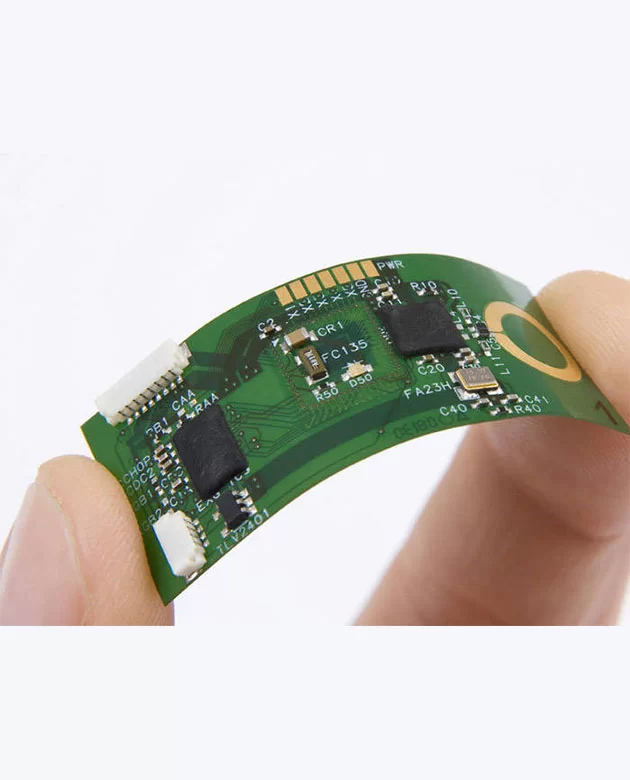

Flex PCB boards or flexible printed circuit boards, as the name suggests, carry out the function of regular PCB boards while being physically flexible.

Bare boards of flexible printed circuit boards are made of flexible materials allowing them to bend and be manipulated as per the designer’s requirements. This feature of bendability and flexibility comes in handy while crafting various new-age gadgets such as wearables.

Benefit of Flex PCB boards

Simplified assembly process due to minimized connection points.

Superior packaging density i.e. reduced package size.

Negligible chances of defects, like defective solder joints and wiring errors.

Improved reliability than rigid PCBs.

Increased freedom of design.

Resistant to vibrations and extreme environments like exposure to chemicals.

Enhanced heat dissipation and better airflow.

Lower assembly costs due to the elimination of wiring harnesses and non-complicated testing processes.

Lesser assembly time which may further reduce costs.

High-density configuration is possible.

Applications

Consumer Electronics, health trackers, fitness wearables, smart watches, Wearables, cameras;

Automobile Industry, airbag systems; Computers, Laptops;

Medical Instruments, ultrasound probes;Telecommunications, Aerospace Industry, Satellites

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.