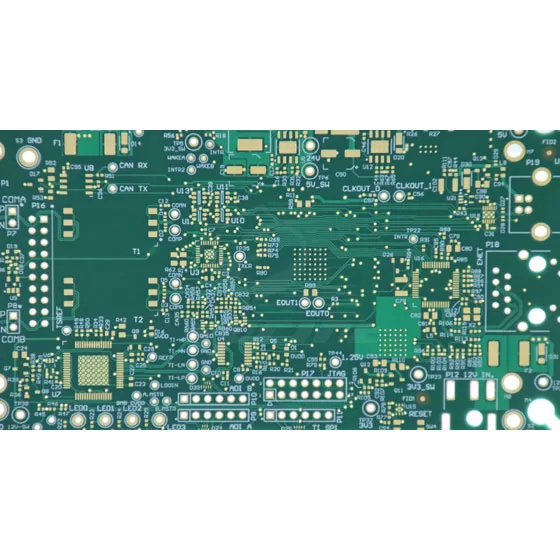

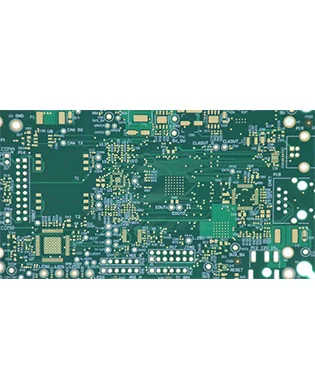

FPGA High-Speed PCB

Data Sheet

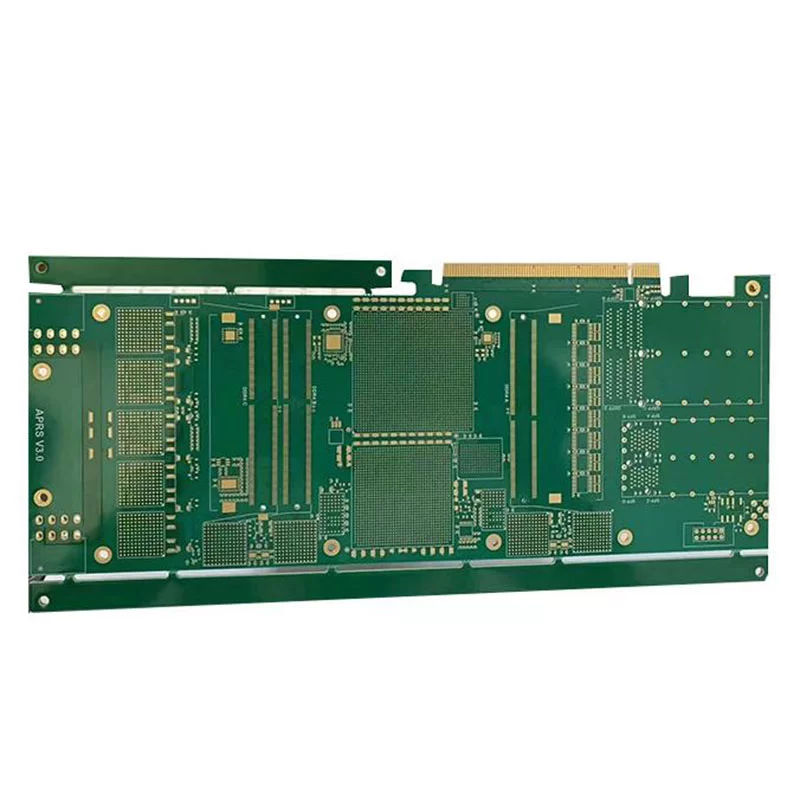

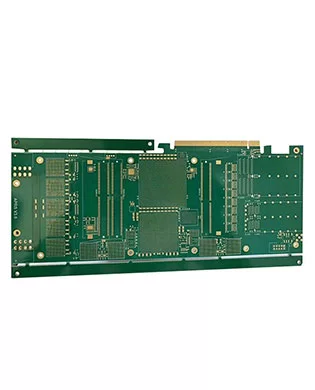

Model: FPGA high-speed circuit board

- Material: TG180

- Layer:10Layers

- Finished Thickness:1.6mm

- Copper Thickness: Inner/outer 1OZ

- Color: Blue/White

- Min Trace/Space: 4mil/4mil

- Surfacet Treatment: Hard Gold 5U

- Application: FPGA high-speed PCB

Benefits of High-Speed PCBs

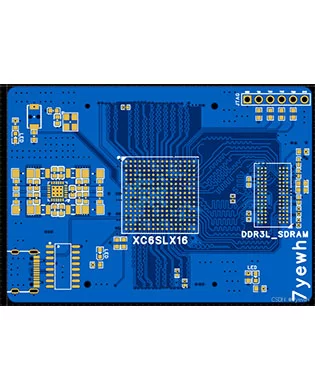

(1) Signal Integrity Assurance: At extremely high signal transmission speeds (e.g., GHz range), ordinary PCB materials cause issues like increased signal attenuation, delay, and crosstalk due to their high dielectric constant (Dk) and dielectric loss factor (Df), severely impairing signal quality and integrity. High-speed PCB materials such as the Rogers series feature lower Dk and Df, reducing signal transmission loss, preserving sharp signal edges, and minimizing signal delay.

- (2) Enhanced Anti-Interference Capability: Electromagnetic interference (EMI) becomes particularly pronounced at high frequencies. High-speed materials enable designers to better manage power/ground layers, create effective shielding and isolation, minimize EMI’s impact on the system, and ensure system stability.

- (3) Complex System Design Requirements: High-speed PCB design often involves multi-layer boards and complex wiring, requiring special laminate structures (e.g., embedded power/ground planes, distributed capacitors, and impedance control technologies). All these demand excellent electrical performance and consistency from the board materials.

About the FPGA High-Speed PCB

With the rapid development of embedded hardware technology, high-speed board design has become a core skill in embedded system design. High-speed board design requires comprehensive capabilities in signal integrity, power integrity, and high-frequency routing. This is particularly challenging when combining FPGAs with high-speed memory.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.