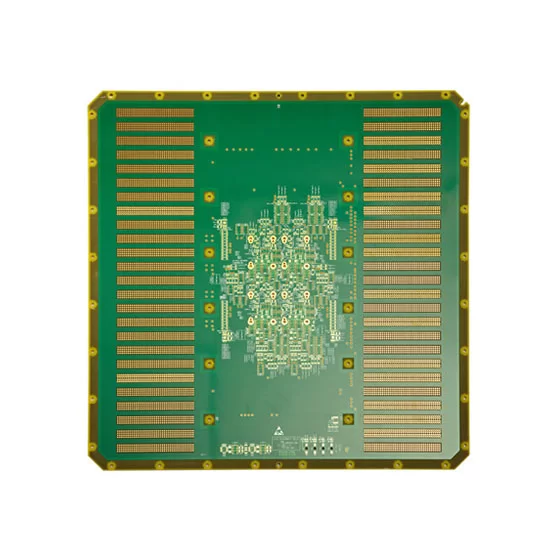

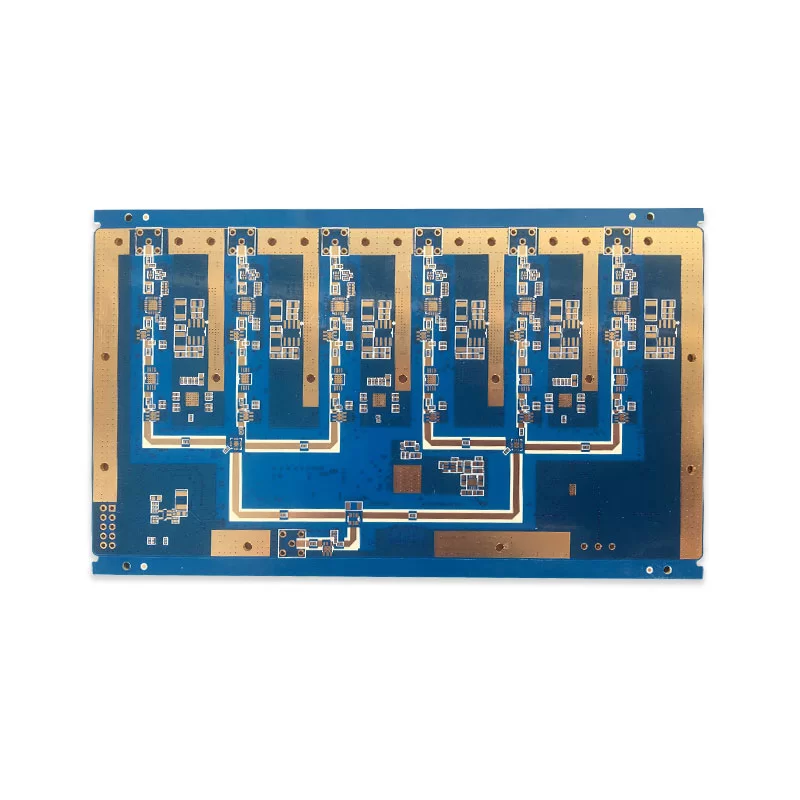

High Speed FR4

About High Speed FR4

A high-speed PCB is a specialized PCB designed to handle high-frequency signals (converting higher frequencies into faster data rates), characterized by high signal transmission speeds and operating frequencies above 1GHz. Its design and manufacturing require special attention to signal integrity, power integrity, and electromagnetic compatibility (EMC/EMI).

Typically, its core material is high-frequency, high-speed copper-clad laminates with low dielectric constant (Dk) and low dielectric loss factor (Df). Additionally, to ensure signal quality and reduce losses, its impedance must be controlled at a low level, and the substrate needs low water absorption. With technological advancement, its market demand continues to grow, finding applications in computer motherboards, industrial control computers, measurement and control instruments, etc.

Characteristics of High Speed FR4

Low Dk/Df Dielectrics: Critical for signal integrity—low Dk reduces attenuation for higher frequencies, low Df minimizes heat. Common options: Rogers 4000, Isola I-Tera, Panasonic Megatron-6.

- Differential Pairs: Balanced routing for equal-opposite signals (Ethernet, HDMI, etc.), with strict predefined impedance; appears as two parallel traces between ICs/ports.

- Impedance Control: Essential for high frequencies (tight tolerances), including differential pair and microstrip/single-ended types.

- Length-Matched Traces: Equal lengths ensure time synchronization (e.g., GMII’s 8 time-sensitive lines), identifiable by sine wave-like compensation curves.

- Special Stackups: 4+ layers with dedicated ground (signal reference) and power planes (high-speed signals avoid power layers); 2+ cores (insulation/crosstalk) and tight dimensional tolerances.

- Trace Geometry: Short, uniform-length traces with no 90° bends (obtuse/curves); length-matched traces may have sine wave patterns.

- EMI Protection: Via stitching (ground-net vias) + dedicated ground plane; weak pull-down resistors protect idle channels.

- Dedicated Power Delivery: Inner-layer power planes (adjacent to ground, reducing EMI), power via delivery to ICs; decoupling capacitors filter noise.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.