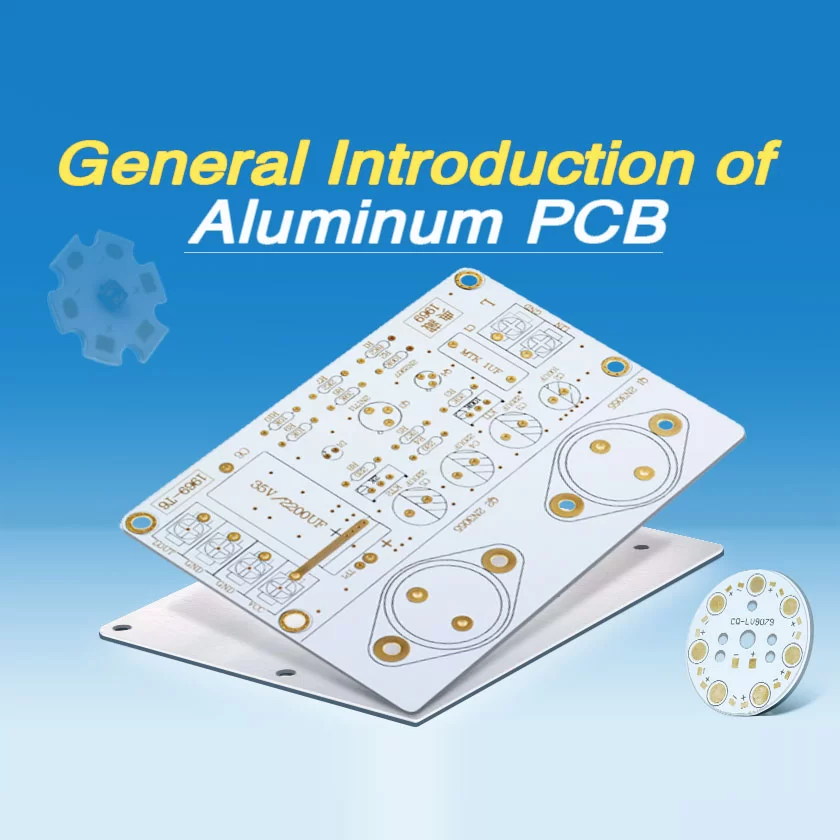

MC PCB Aluminum PCB

What is Aluminum PCB?

Aluminum PCB, also known as metal core PCB or aluminum core PCB, is a circuit board with aluminum substrate. Aluminum-based material has good thermal conductivity and can effectively conduct heat away from key components, thereby improving the stability and durability of the circuit board in high-power and high-temperature environments. Aluminum PCBs are widely used in fields with high thermal management requirements such as LED lighting, power modules, and automotive electronics.

Advantages of Double-sided Aluminum PCB

1. Excellent Thermal Conductivity

Aluminum's efficient thermal conductivity allows for rapid heat transfer, effectively reducing the operating temperature of electronic components and ensuring stable device operation.

- 2. Excellent Electrical PerformanceThe conductive layer of the aluminum substrate is made of a highly conductive material, providing a stable and reliable electrical connection, minimizing signal interference and transmission loss, and ensuring accurate and effective signal transmission.

- 3. Excellent ProcessabilityAluminum substrates offer high mechanical strength, meeting the diverse design requirements of various electronic devices and significantly improving production efficiency and product flexibility.

- 4. Excellent InsulationThe insulating layer within the aluminum substrate effectively isolates the conductive layer, preventing electrical faults such as short circuits, thereby ensuring the safety and stability of electronic devices.

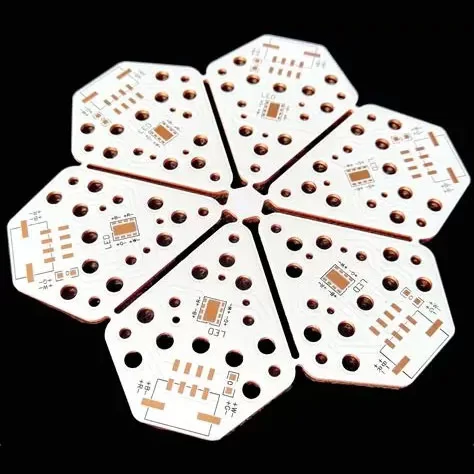

Applications

high-power LED lights, electronics in the automotive,high heat generation devices, switch-mode power supplies (SMPS), engine control unit (ECUs), motor controller, battery management system, LED headlights, programmable logic controllers (PLCs), power delivery units, Telecommunication Equipment, antennas, routers, network switches, Renewable Energy System, high-performance audio amplifiers, gaming consoles and computer graphic cards etc.

Challenge

1. Limited Layer Count

Aluminium circuit boards are limited to only single-layer or double-layer fabrication due to the nature of their production process. This layer limitation restricts their suitability for complex multilayer designs.

- 2. Poor FlexibilityThe flexibility of aluminium core PCB is really low when compared to PCBs made from materials like polyimide and polyester. This rigidity of aluminum PCB board can be challenging in applications where the PCB needs to undergo repeated bending or flexing.

- 3. Thermal Expansion MismatchThe coefficient of thermal expansion is higher for aluminum PCB when it is compared with some electronic components and solder materials. This mismatch of thermal expansion can lead to mechanical stress, failure of solder joints and sometimes delamination which all will compromise the reliability of the PCB assembly.

- 4. Cost ConsiderationAlthough alu PCBs have a good role in thermal management, they are a bit more expensive compared to traditional PCB substrates like FR-4. Because of the cost of aluminum substrate PCB, the specialized fabrication process used and additional surface finish options which are all contributing to increased manufacturing cost of alu PCB.

FAQ

Aluminum substrates have high requirements for storage methods: should be stored in a dry, constant temperature environment and sealed with anti-static vacuum packaging to avoid copper surface oxidation and performance degradation of the aluminum PCB board before SMT.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.