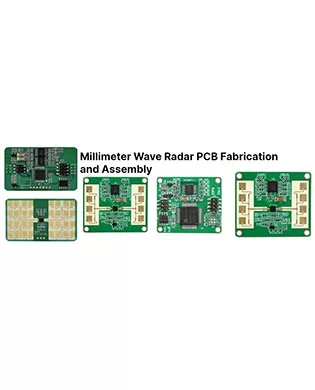

Millimeter Wave Antenna PCBs

Data Sheet

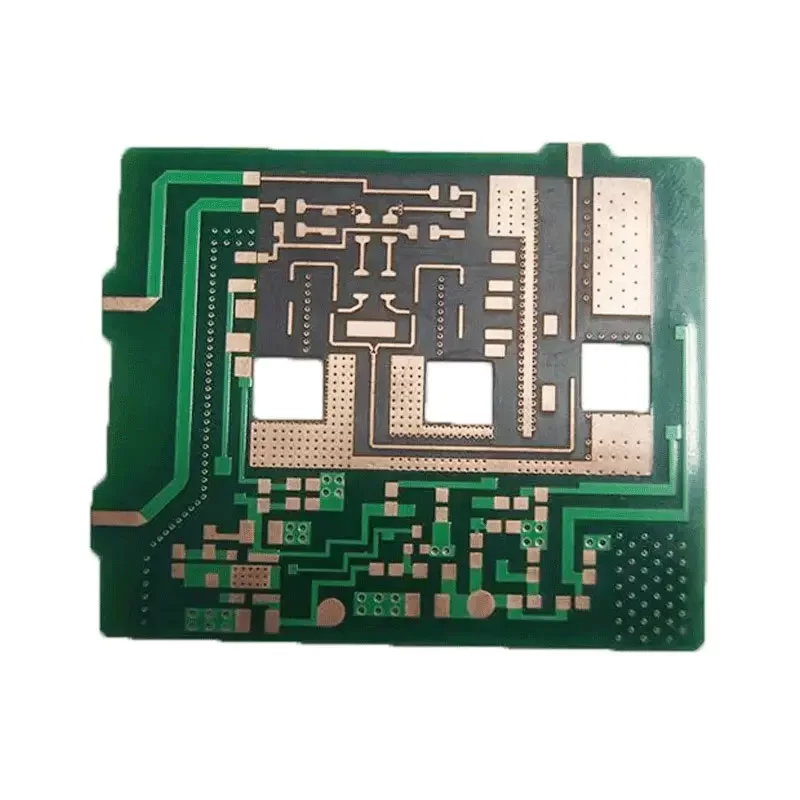

Model: Millimeter Wave Antenna PCBs

- Material: Teflon/Ceramic/FR-4

- Quality standard: IPC-6012

- Dielectric constant: 2.0-16

- Layers:1 Layer -34 layer

- Thickness:0.254mm-6.0mm

- Copper thickness: H/H-30Z

- Surface technology: Silver(Can choose Gold or OSP)

- Application: GPS Antenna PCB,WiFi Antenna PCB,5G Antenna PCB

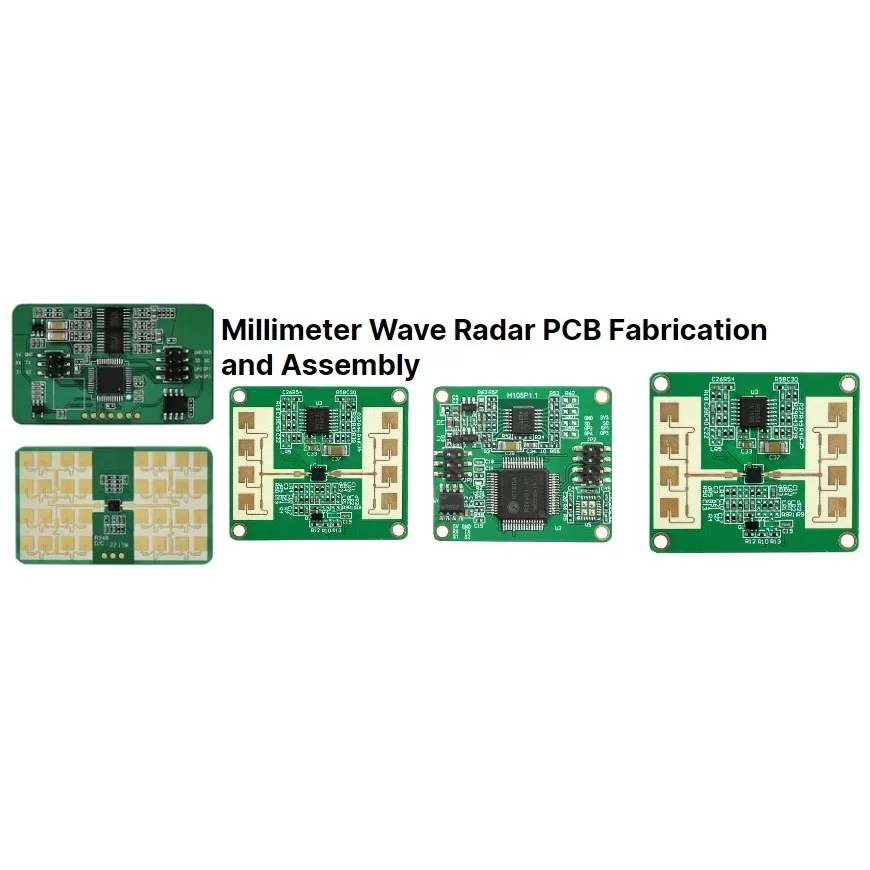

Benefits of Millimeter-Wave Antenna PCBs

'-Millimeter-wave technology enables extremely high data rates, supporting the growing demands of bandwidth-intensive applications such as 5G and high-resolution imaging.

- -In radar and imaging applications, millimeter-wave technology offers higher resolution and accuracy, enabling precise object detection and detailed analysis.

- -Millimeter-wave antenna PCBs enable compact and lightweight designs, making them suitable for mobile devices, IoT applications, and other space-constrained environments.

- -Millimeter-wave technology supports low-latency communications, which is critical for real-time applications such as autonomous driving and industrial automation.

- -Millimeter-wave frequencies offer wide bandwidth, enabling multi-channel and high-capacity communication links.

- -Millimeter-wave antenna PCBs can be used in a wide range of applications, from wireless communications and radar systems to high-resolution imaging and IoT devices.

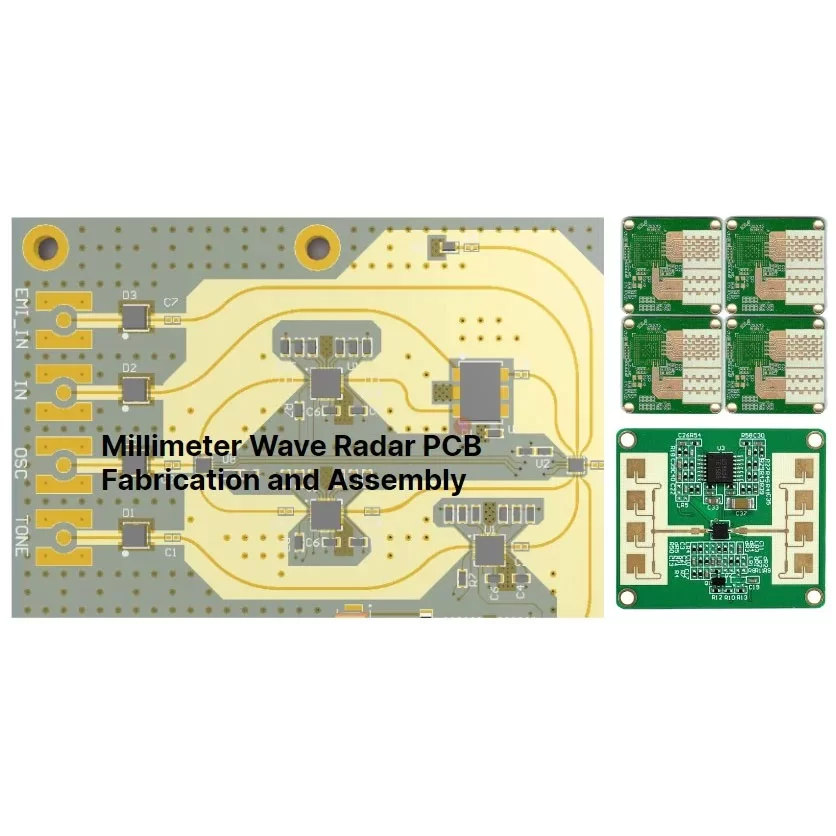

What materials are commonly used for millimeter wave antenna PCBs?

Common materials used in millimeter-wave antenna PCBs include high-frequency substrates such as Rogers RO3000 and RO4000 series, polytetrafluoroethylene (PTFE), and other low-loss laminates. Conductive materials such as copper, sometimes plated with gold, are used for antenna elements and microstrip lines. Advanced dielectric materials and metal shielding are also used to ensure signal integrity and prevent interference.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.