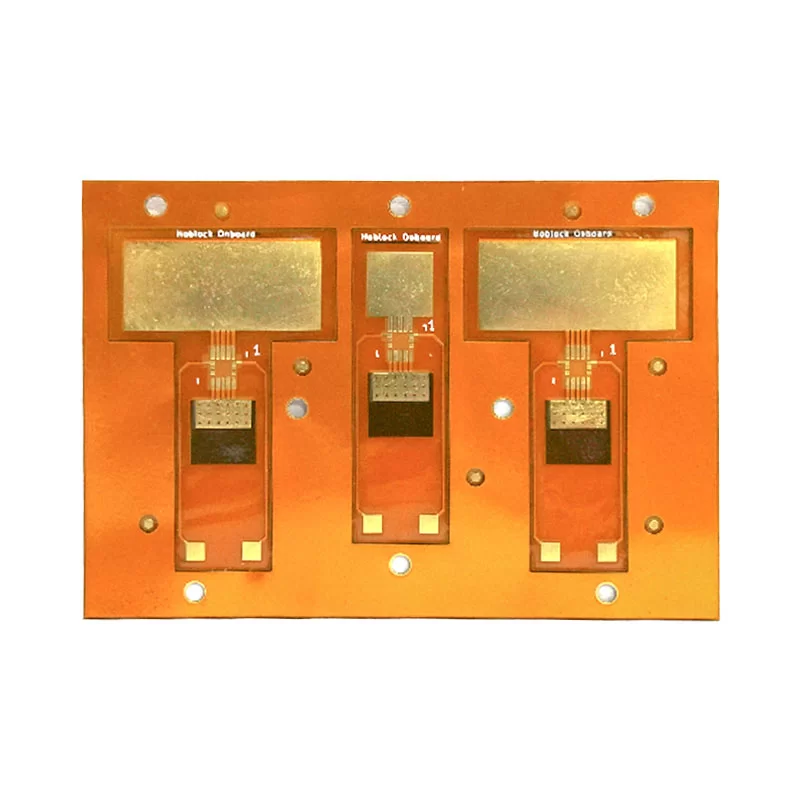

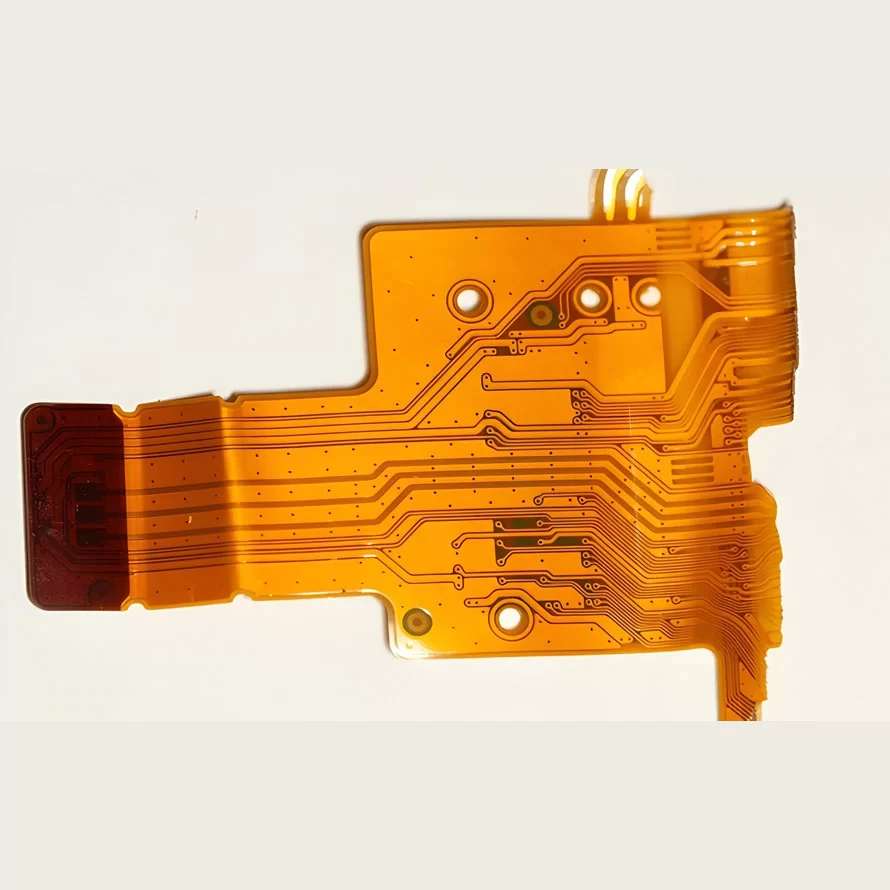

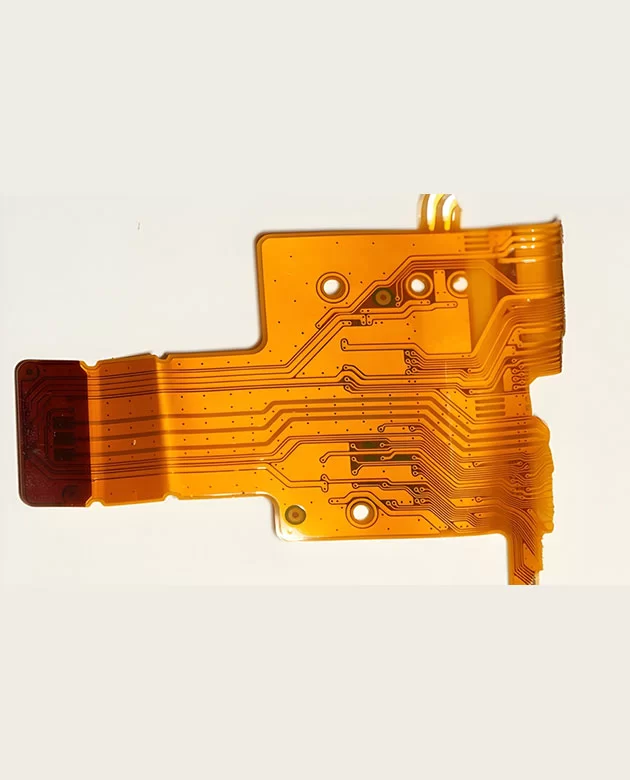

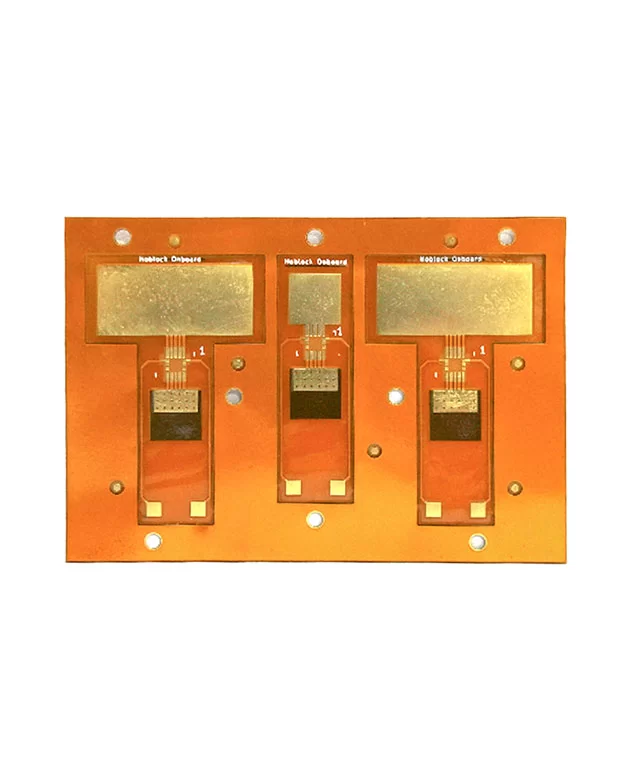

Polyimide Flex PCB

What is Polyimide PCB?

Polyimide PCB is a printed circuit board made of polyimide material. Polyimide is a lightweight, flexible material with excellent electrical properties and low thermal expansion. Polyimide is a type of polymeric material that shows thermal stability in high temperatures with high chemical resistance.

The first polyimide film, also called Kapton. It usually appears as a translucent, amber color film material.

Advantages of Polyimide Flex PCB

Flexibility

Polyimide may come in film structures which grants it certain advantages like bendability and flexibility. Even if polyimide circuit board is highly flexible, it also has very good tensile strength which means it is capable of bearing heavy load.

- Resistance to ChemicalsPolyimide PCB material is also resistant to corrosive chemicals. Its chemical structure does not degrade easily when interacting with solvents and substances. This property makes it even more suitable for medical applications.

- Thermal StabilityPolyimide circuit board exhibits resistance to degradation even when subjected to high temperatures. The thermal stability of polymers is systematically measured using thermogravimetric analysis, wherein loss in mass is measured as a function of time at constant temperature. It can withstand 300 to 500 degrees Celsius, and it has the highest maximum working temperature among other polymers.

- Good Electrical PropertiesPolyimide circuit board also boasts of its favorable electrical properties such as low dielectric constant and good electrical insulation properties. It is particularly useful for high-voltage industrial applications. The low dielectric constant of polyimide circuit boards helps in maintaining signal integrity and in the reduction of unwanted capacitance between neighboring conductive traces.

Applications of Polyimide Flex PCB

Medical

Medical devices require portable sensing devices with mechanical flexibility. Polyimide flex circuit has these advantages making it a popular material choice for medical applications. For instance, displacement sensors for biomedical devices contain polyimide PCB due to its easy integration with various electronics. The use of non-invasive portable systems for monitoring health signals in a real-time manner has a better advantage than bulky and wired systems.

- CommercialPolyimide PCB is also widely used in commercial applications like computers, televisions, smartphones, and wearables, which require compact and light material. Smaller devices are made possible due to inherent low mechanical stiffness and thermal stability.

- AutomotiveElectronic devices inside vehicles extensively use polyimide flex circuits due to their ability to be contained in small spaces of various geometries. Vehicles’ audio systems, cameras, controlling, and sensing devices have polyimide circuit boards.

- AerospaceThe reduced weight and excellent thermal characteristics of polyimide PCB material make it a primary option for space electronics. Spacecraft electronics possess high-reliability components that can be satisfied by polyimide flex PCB. Flexible PCBs can substitute bulky wires and cables for non-planar dimensions for aerospace applications.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.