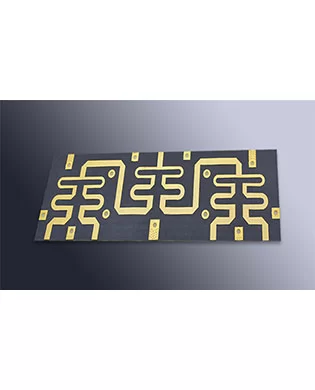

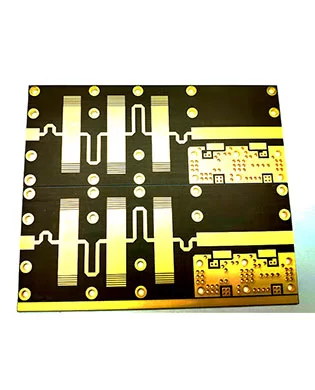

PTFE F4BM255 High Frequency PCB Board

Data Sheet

Model: PTFE F4BM255 High Frequency Board

- Layer: 2Layers

- Dielectric constant: 2.2

- Dielectric Thickness: 0.8mm

- Thermal Conductivity: 0.3~0.5w/m.k

- Flammability: UL 94-V-0

- Finished Thickness:1.0MM

- Copper Thickness:1OZ

- Surface Treatment: OSP

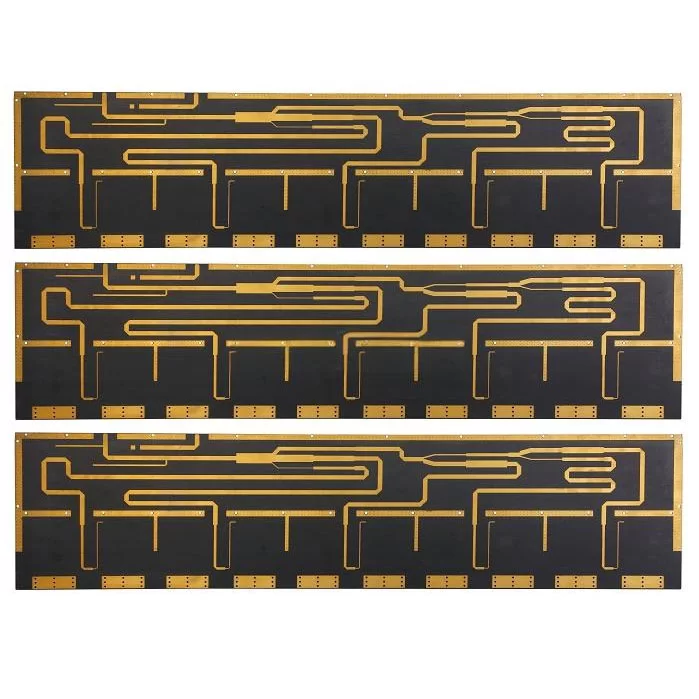

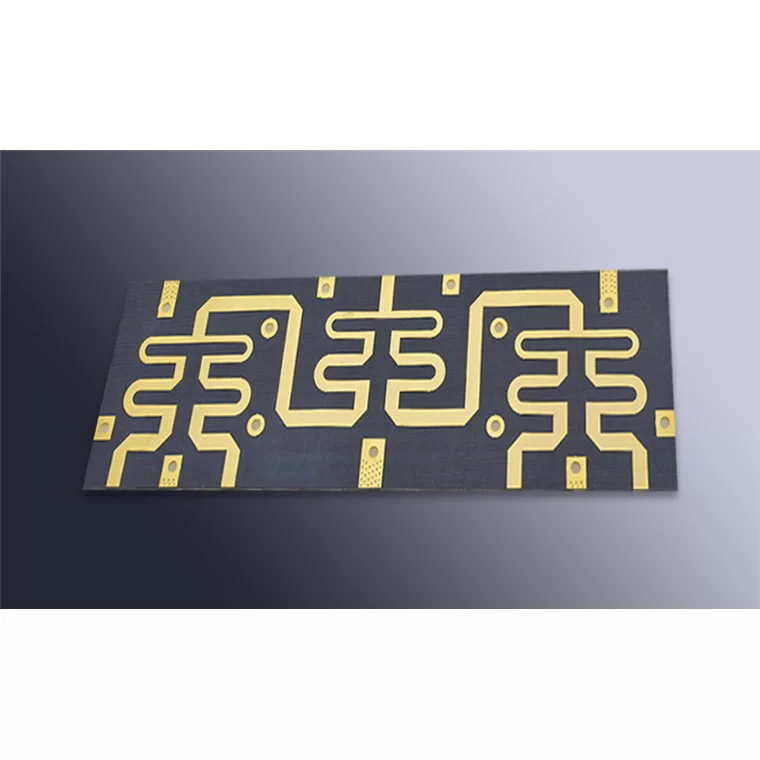

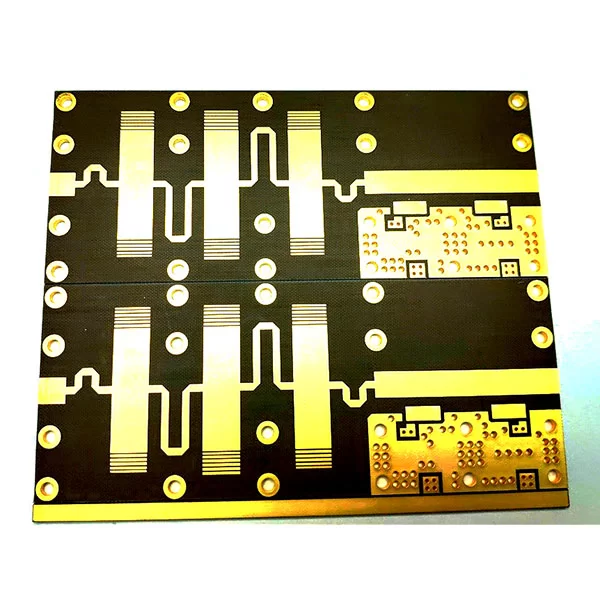

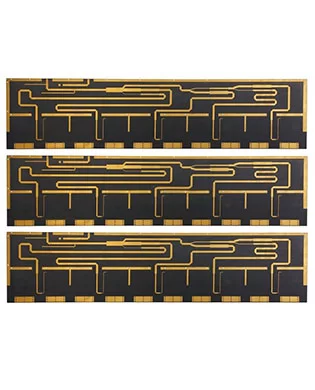

- Application: Micro-wave Antenna pcb

F4BM255 High Frequency PCB Board

The F4BM255 is manufactured using a scientifically formulated and rigorously pressed glass cloth, prepreg, and PTFE (polytetrafluoroethylene) resin. Its electrical performance improves significantly over the F4B series, primarily through a wider dielectric constant range, lower dielectric loss tangent, increased resistance, and more stable performance. The F4BM series is a widely used and highly cost-effective product, and the F4BM255 is the most widely used member of the F4BM series.

Applications

Phase shifters, passive components, power splitters, couplers, combiners, feed networks, phased array antennas, satellite communications, base station antennas

Characteristics

Dielectric Constant (Dk): 2.55 ± 0.05 (values tested at 10 GHz)

- Dissipation Factor (DF): 0.0013 (values tested at 10 GHz);0.0018 (values tested at 20 GHz)

- Thickness: 0.127 ± 0.01 mm (dielectric thickness), 0.254 ± 0.02 mm, 0.508 ± 0.04 mm, 0.762 ± 0.05 mm, 1.016 ± 0.05 mm, 1.524 ± 0.06 mm, 2.0 ± 0.08 mm, 3.0 ± 0.09 mm

- Dimensions: Standard sizes: 460 x 610 mm, 500 x 600 mm, 850 x 1200 mm, 914 x 1220 mm, 1000 x 1200 mm

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.