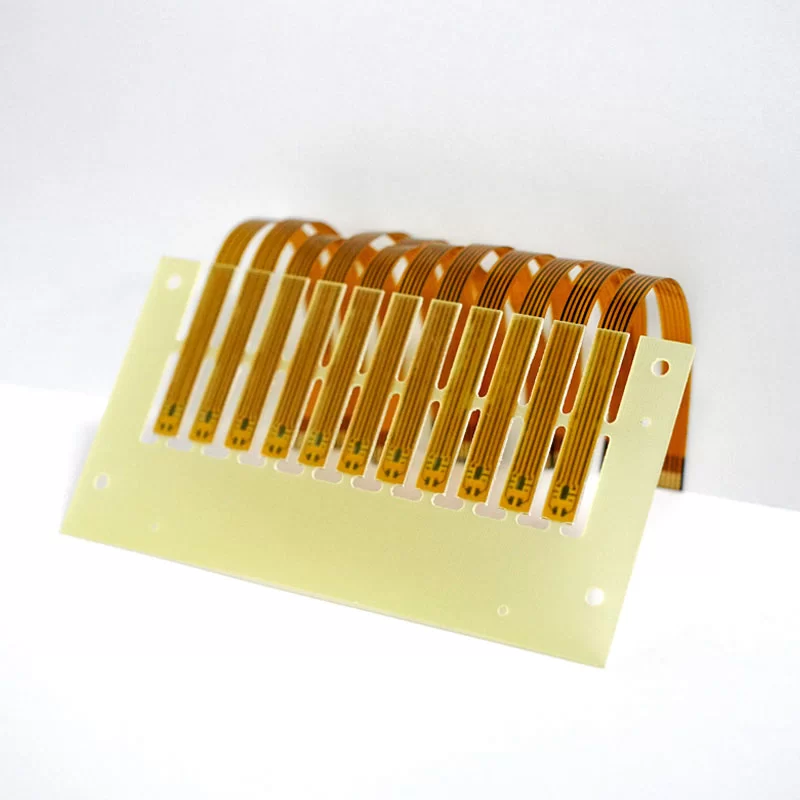

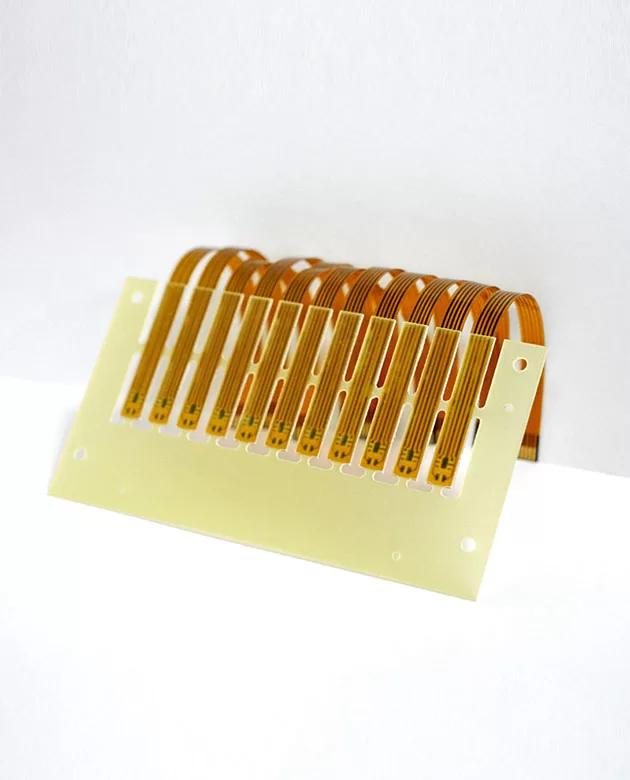

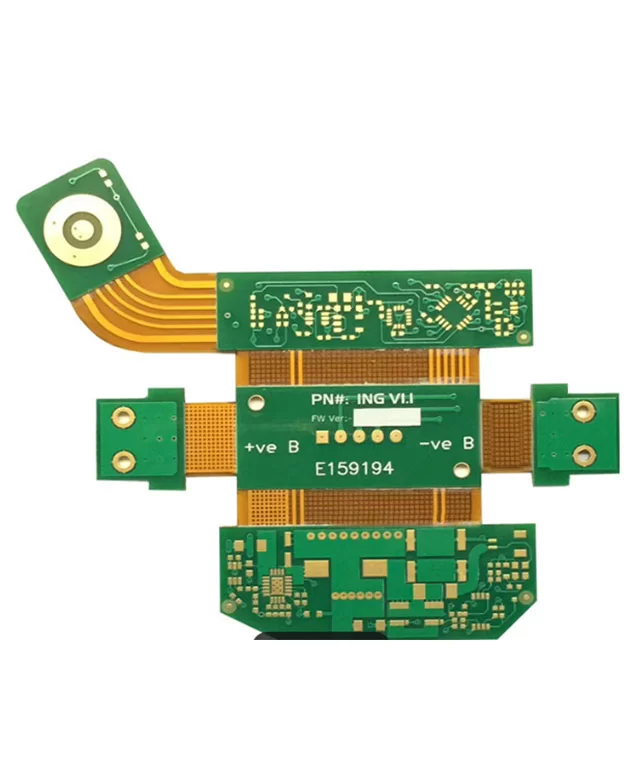

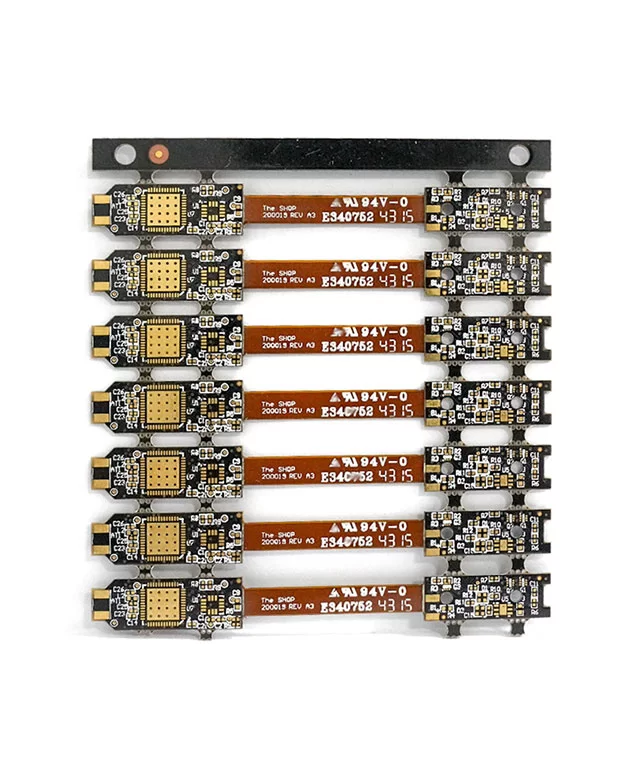

Rigid-flex PCB FR4+PI

Layer: 4L(Fr4)+2L(PI)

Material: Fr4+PI

Board Thickness: 0.15mm

Fr4 reinforcement: 0.2mm

Total Thickness: 0.35mm

Min Via Diameter: 0.2mm

Copper Thickness: 18μm

Trace Width/Spacing: 4/4mil

Surface Finish: ENIG1U”

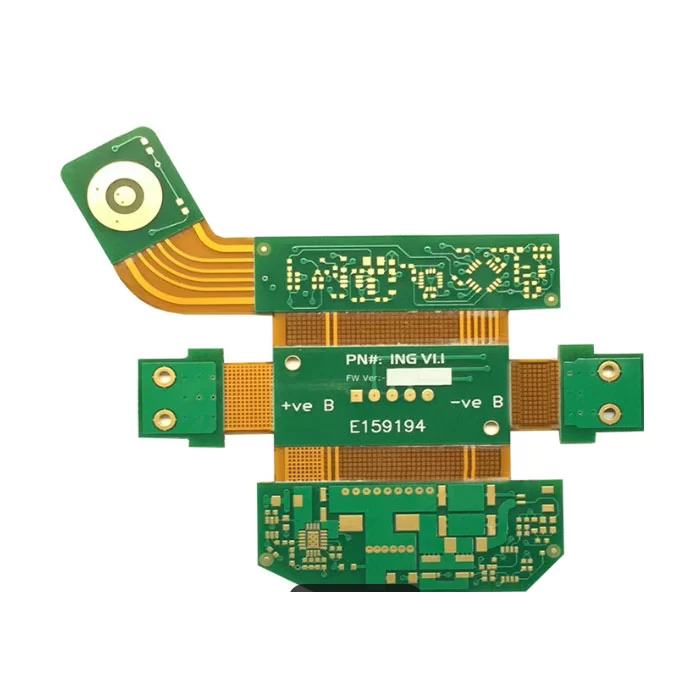

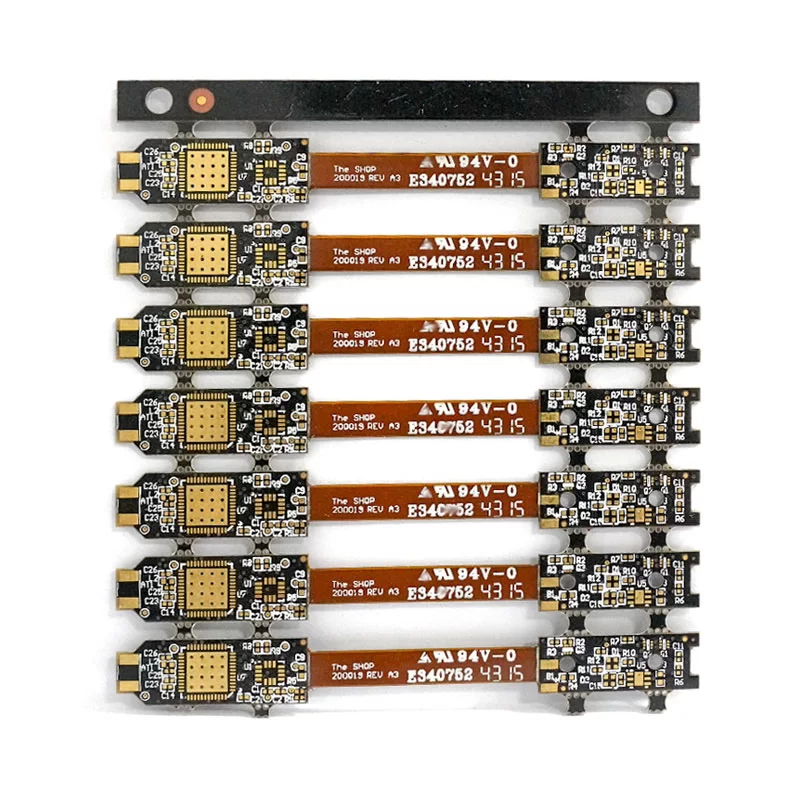

What is Rigid-flex PCBs?

Rigid-flex PCBs are a combination of the features of both rigid and flexible PCBs. In this type of flex PCB board, only the required areas of the PCB are made with flexible materials that help connect the rigid parts of the circuit. This type of structuring takes the benefits of both having a flexible, lightweight circuit and a mechanically stable and rigid layer

Advantages

1. Reduced Weight: The flexible portion of the rigid-flex printed circuit boards contributes to the weight reduction of the overall PCB. Having lesser weight than other PCB types, rigid-flex PCB is beneficial for portable devices which need to be inserted, carried, held, or worn.

2. Better Flexibility: Due to the combined elements of flex and rigid circuits, rigid flex printed circuit boards can adapt well to complex and irregular geometries. Rigid-flex PCB can fit into tiny spaces and can follow the contour or surface thus, allowing different shapes and arrangements.

- 3. Smaller Device: Rigid-flex PCB can fit into tiny spaces for smaller device geometries. PCB designers can disregard the use of bulky connectors, cables, and wires and resort to a single package with enhanced performance and reliability.

- 4. High Reliability: Rigid-flex printed circuit board gets the benefit of rigid board’s mechanical stability and flexible circuit’s stress absorption capabilities which improves interconnect reliability. They are built to last, with their ability to endure vibration and mechanical and thermal stresses.

Application

Medical Products; Industrial Sectors, CNC machines, stepper motors; Consumer Electronics, wearables, include smart watches, glasses, ear pods and suits, smartphones, media players and game consoles etc.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.