RO4350B

Data Sheet

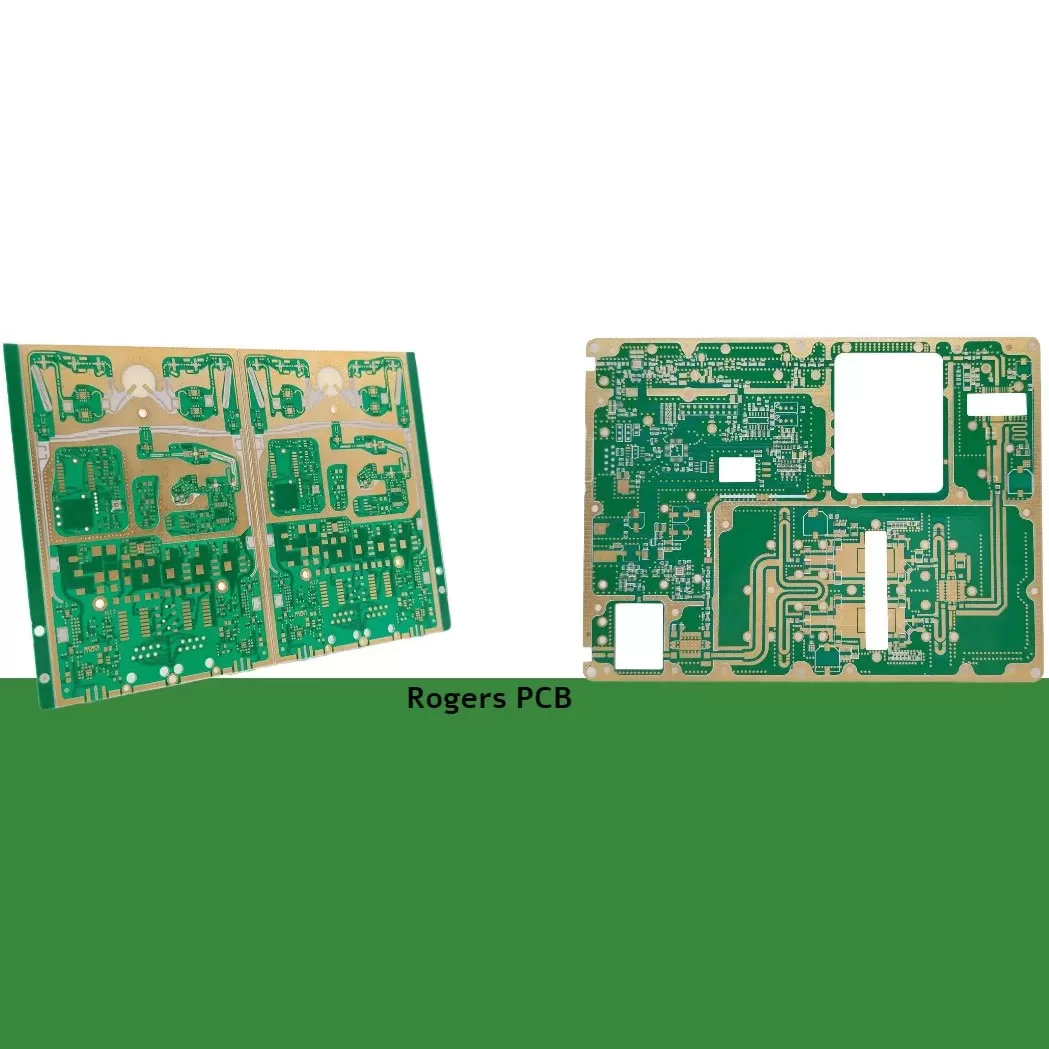

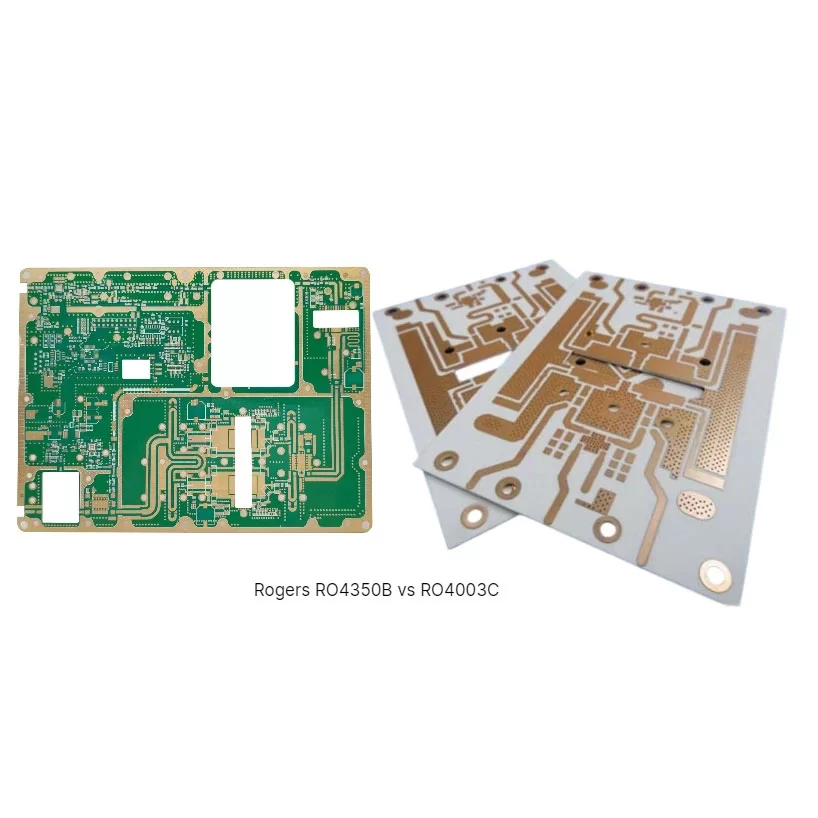

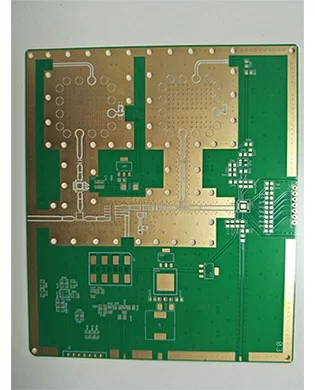

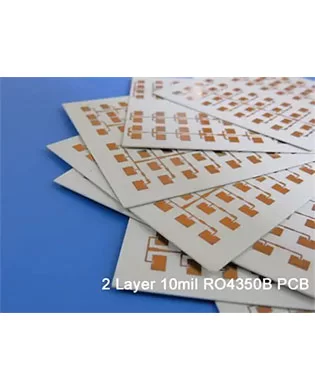

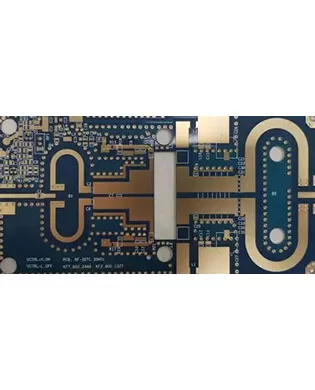

Model: Rogers RO4350B

Material: rogers 4350 material

- Layer: 2 layer pcb

- Rogers 4350 dielectric Thickness:0.254-1.524mm

- Ro4350b dielectric constant:3.48

- Thermal Conductivity:0.69w/m.k

- Copper Thickness:Base 0.5OZ,Finised 1OZ

- Finished Thickness:0.35mm-1.7mm

- Surface Treatment: Immersion Gold/Silver

- Trace/ Spacing: 4mil/4mil

About RO4350B

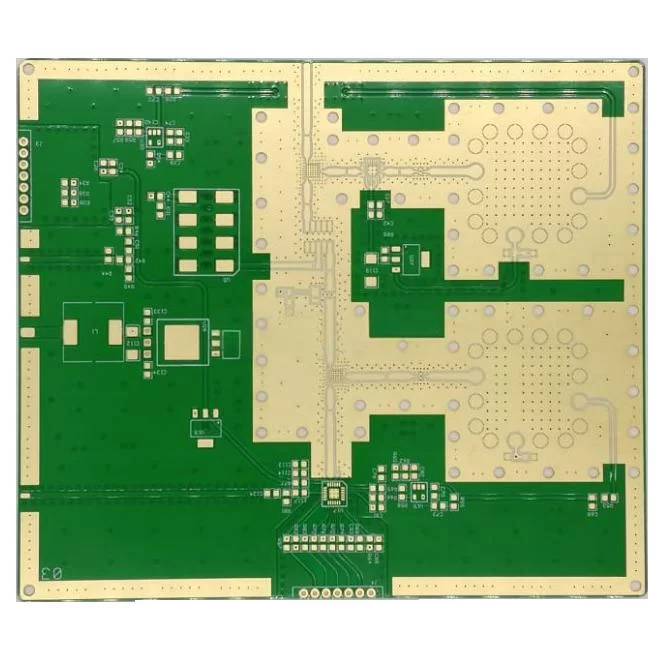

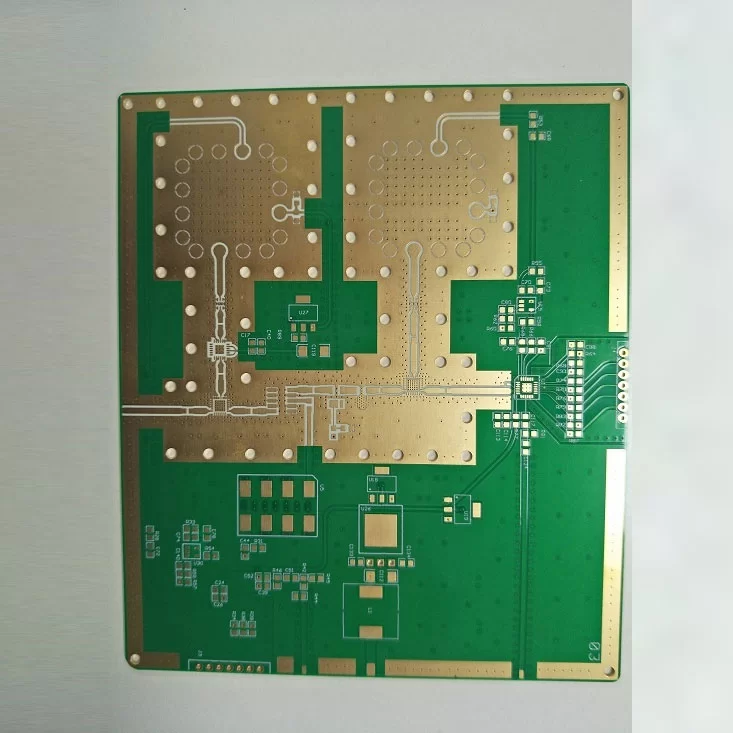

RO4350B laminates offer tightly controlled dielectric constants (Dk) and low loss characteristics, and can be processed using the same methods as standard epoxy/glass. Unlike PTFE, RO4350B laminates do not require specialized through-hole processing or handling procedures, resulting in significantly lower processing costs than traditional microwave laminates. The material also achieves a UL 94 V-0 flame retardancy rating, making it suitable for active device and high-power RF designs.

Advantages

1. Low RF loss

2. Minimal dielectric constant fluctuation with temperature

3. Low z-axis thermal expansion coefficient

- 4. Low board expansion coefficient

- 5. Low dielectric constant tolerance

- 6. Stable electrical characteristics at different frequencies

- 7. Easy to mass produce and multi-layer mixing, high cost-effectiveness

Applications

Cellular base station antennas,Power amplifiers, Microwave(P2P)connections, Automotive radars and sensors,

Radio frequency identification (RFID) tags, Real-time satellite LNBs

Characteristics

Dk 3.48 +/- 0.05

Df 0.0037 @ 10 GHz

Z-axis thermal expansion coefficient 32 ppm/°C

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.