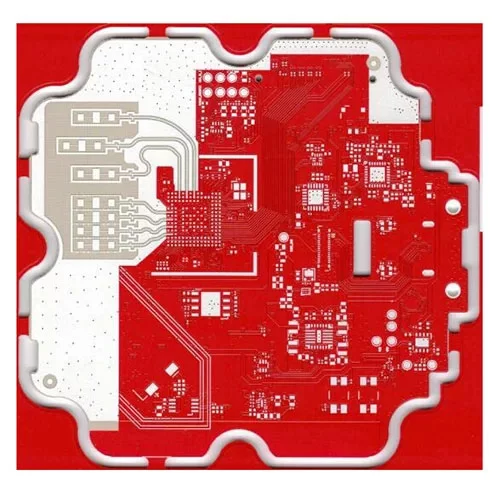

Rogers RO4534 Microwave Printed Circuit Board

Data Sheet

Model: Rogers RO4534 High Frequency Board

- Material: Ceramic PTFE Composite Rogers RO4534

DK: 3.0±0.05

- Layer: 2Layers

- DielectricsThickness:0.762mm(30mil)

- Finished Thickness:0.86mm

- Material CoThickness:0.5OZ HH/HH

- Finished Co Thickness:1OZ(35μm)

- SurfaceTreatment:Immersion Gold

- Min Trace/Space: 4mil/4mil

- Application:PCB antenna,active antenna array for 5G,lOT pcb

Core Features of RO4534™ PCBs

1. Excellent Electrical Performance

- Low Dielectric Constant and Dissipation Factor: RO4534™ boasts a dielectric constant (Dk) of 3.4 ± 0.08 and a dissipation factor (Df) as low as 0.0022 (2.5 GHz), significantly reducing energy loss and latency in signal transmission. This makes it particularly suitable for high-frequency applications in the millimeter-wave band, such as 5G and 24 GHz automotive radar.

- Low Passive Intermodulation (PIM): Its copper foil surface treatment optimizes the smoothness of the copper-dielectric interface, significantly reducing PIM interference. This performance excels in applications such as base station antennas, with a typical PIM value of -157 dBc.

- 2. Good Physical and Thermal Stability- High Thermal Conductivity (0.6 W/m·K): Improves heat dissipation efficiency, ensuring stable operation in high-power scenarios. – Low Coefficient of Thermal Expansion (Z-axis CTE 46 ppm/°C): Matches the thermal expansion coefficient of copper foil, reducing the risk of deformation caused by temperature changes and ensuring the reliability of multilayer boards (MLBs).3. Processing Compatibility- RO4534™ is compatible with standard FR-4 processes, requiring no special via preparation or chemical processes, reducing manufacturing costs. It supports laser drilling and precision circuit design, meeting the stringent precision requirements of high-frequency circuits.

RO4534™ Processing and Technical Support

1. Optimized Processing Parameters

- Drilling Process: Recommended drill speeds are 300-500 SFM and a feed rate of 0.002"-0.004"/rev to avoid copper foil damage at high speeds.

- Surface Treatment: Electroless or electroplating processes are used to enhance copper adhesion and ensure high-frequency signal integrity.

- 2. Multilayer Board Design Support- RO4534™ can be used with RO4000® series prepregs to achieve high-density multilayer board structures, meeting the needs of complex circuit designs.

Applications of RO4534™

1. 5G Communication Base Stations and Antenna Systems

- In 5G base stations, RO4534™ optimizes microstrip and stripline designs with its low loss and precise impedance control, reducing signal latency and improving the transmission efficiency and coverage of antenna arrays.

- 2. Automotive Millimeter-Wave Radar- Suitable for 76-81 GHz automotive radar sensors, its high-frequency performance enables high-precision environmental perception, while its high-temperature and chemical resistance ensures long-term stable operation within the engine compartment.

- 3. Satellite Navigation and Aerospace Equipment- In satellite receivers, RO4534™'s low dissipation factor ensures the integrity of weak signals, while its thermal and dimensional stability withstands extreme temperature and vibration environments.

- 4. Industrial Radar and IoT Devices- For short-range industrial radars in the 60-81 GHz range, RO4534™ provides low insertion loss and stable RF performance in the millimeter-wave band, supporting high-precision detection and data transmission.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.