Smart Home PCBA

What is Smart Home PCB?

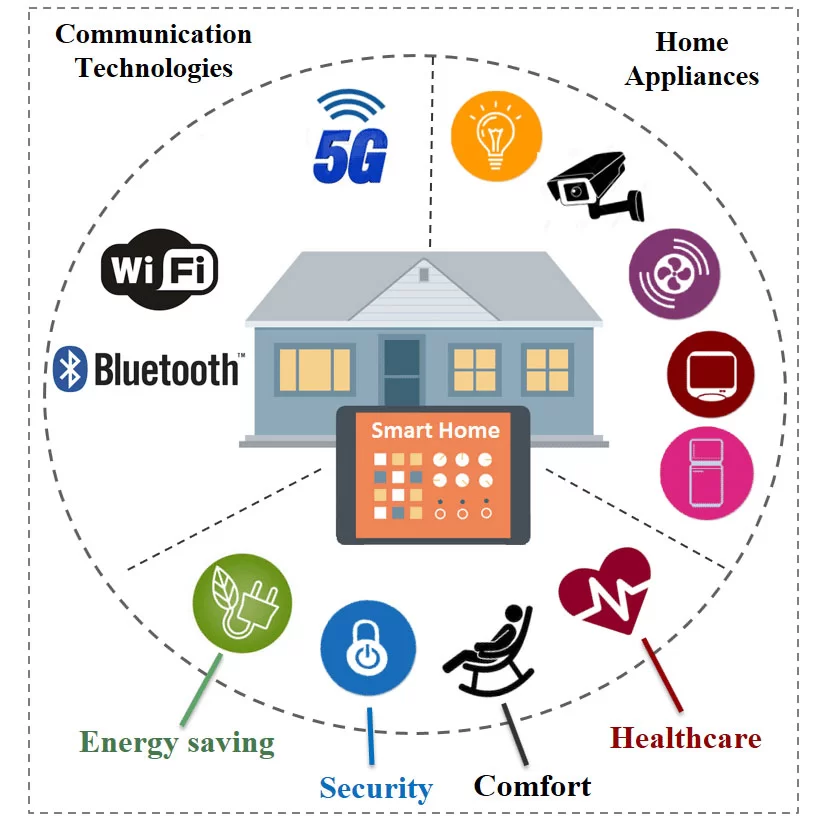

A Smart Home PCB is the backbone of various smart home devices. It’s a platform that houses electronic components, including microcontrollers, sensors, and connectors, enabling communication and control within a smart home ecosystem.

These PCBs are designed to facilitate the functionality of devices like smart lights, thermostats, security systems, and more, allowing them to connect, process data, and interact with users or other devices within the home. It serves as the central hub or control unit within smart home devices. It’s a flat board made of insulating material, usually fiberglass, with conductive pathways etched or printed onto its surface.

Smart Home PCB Assembly

A Smart Home Printed Circuit Board Assembly serves as the backbone of smart home devices, facilitating their functionality and connectivity.

It’s a complex integration of electronic components on a board designed specifically to control and coordinate various tasks within a smart home ecosystem. The integration and interoperability of these PCBs determine the efficiency and effectiveness of the smart home system.

These PCBs often serve as the central control hub within a smart home ecosystem. They manage the communication between different devices, allowing users to control and coordinate them through a central interface, often a smart phone app or a smart home assistant.

Efficient power management circuits are embedded within these PCBs, ensuring optimal power distribution and consumption across devices. This can include power-saving modes and efficient voltage regulation systems.

Engineers focus on compactness, power efficiency, and reliability in designing Smart Home PCBA.

Factors like thermal management, signal integrity, and compatibility with various protocols are crucial. Security measures are integrated to safeguard against unauthorized access or cyber threats. It integrates with smart home devices like thermostats, security cameras, lighting systems, and appliances.

It enables them to be remotely controlled via smartphones or voice assistants, schedule tasks, or respond to predefined conditions (e.g., turning off lights when no motion is detected). Ongoing advancements include miniaturization for smaller form factors, increased processing power for faster operations, and enhanced connectivity options for seamless integration with other smart devices and platforms.

What role does PCBA play in the control and use of smart home appliances?

1. Providing Precise Control and Monitoring

As the core of smart home appliances, the PCBA (Printed Circuit Board Assembly) carries the functions of control and monitoring systems. Through microprocessors, sensors, and other components on the PCBA, smart home appliances can monitor environmental parameters such as temperature, humidity, and light intensity in real time. This data, processed by the PCBA, enables precise control of the appliance's operation, ensuring the stability and reliability of the equipment.

2. Achieving Remote Control and Interoperability

PCBA technology enables smart home appliances to connect to the internet, thus achieving remote control. Through mobile applications or smart home systems, users can remotely monitor and control home appliances anytime, anywhere. The intelligent control function of the PCBA makes it easier for users to manage their home devices, improving comfort and convenience.

- 3. Enhancing the Intelligent Functions of Home AppliancesContinuous advancements in PCBA technology have enabled smart home appliances to possess more intelligent functions. For example, smart refrigerators can automatically order groceries based on user shopping habits, and smart washing machines can automatically select the best washing program based on the type of clothing. These intelligent functions greatly improve the intelligence level of home appliances, providing users with a more convenient and intelligent living experience.

- 4. Improved Energy Efficiency and Environmental FriendlinessPCBA technology not only optimizes the performance of home appliances but also improves energy efficiency and reduces energy consumption. Through intelligent control systems on PCBAs, appliances can adjust power and operating modes according to usage needs, thereby saving energy. Furthermore, PCBAs enable intelligent management of equipment, extending the lifespan of home appliances and reducing environmental pollution.

Application

1. Smart Home Control Centers

PCBA manufacturing technology is widely used in the production of smart home control centers. These control centers can connect to various smart devices, such as smart lighting, smart temperature control systems, and security systems. PCBA technology ensures that these centers can efficiently process various commands, enabling remote control and automated management of smart home devices.

2. Smart Kitchen Appliances

In smart kitchen appliances, PCBA technology enables devices to achieve precise temperature control and timer functions. For example, smart ovens and rice cookers utilize PCBA technology to automatically adjust temperature and time based on the type and weight of ingredients, ensuring perfect food preparation.

3. Smart Appliance Sensors

Various sensors in smart appliances (such as temperature and humidity sensors) are manufactured using PCBA technology. These sensors can detect changes in the surrounding environment and transmit data to the control system. This intelligent sensor application allows home appliances to better adapt to user needs, providing a more comfortable and safer user experience.

4. Smart Security Monitoring Systems

PCBA technology plays a crucial role in smart security monitoring systems. For example, smart cameras utilize PCBA technology to achieve high-definition video capture, image processing, and remote access. Meanwhile, PCBA technology is also used to manufacture intrusion detection sensors to ensure home security.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.