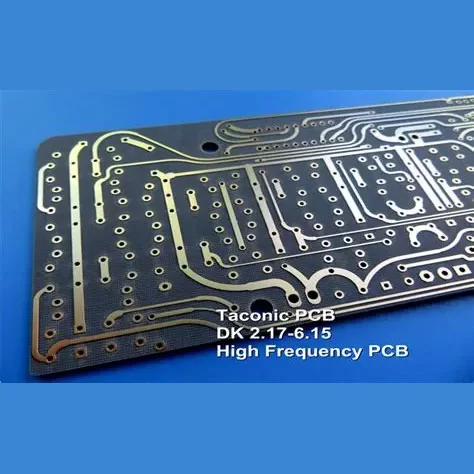

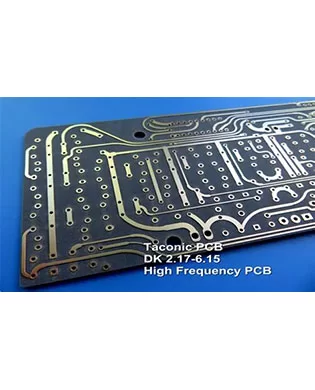

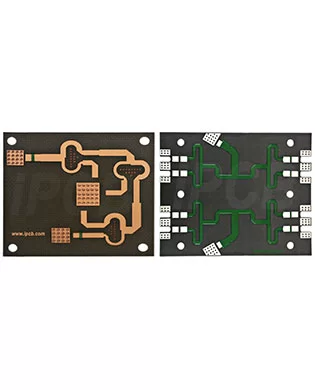

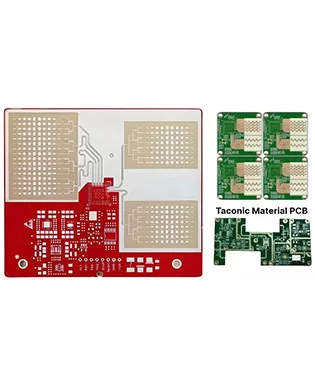

Taconic PCB

What is Taconic PCB?

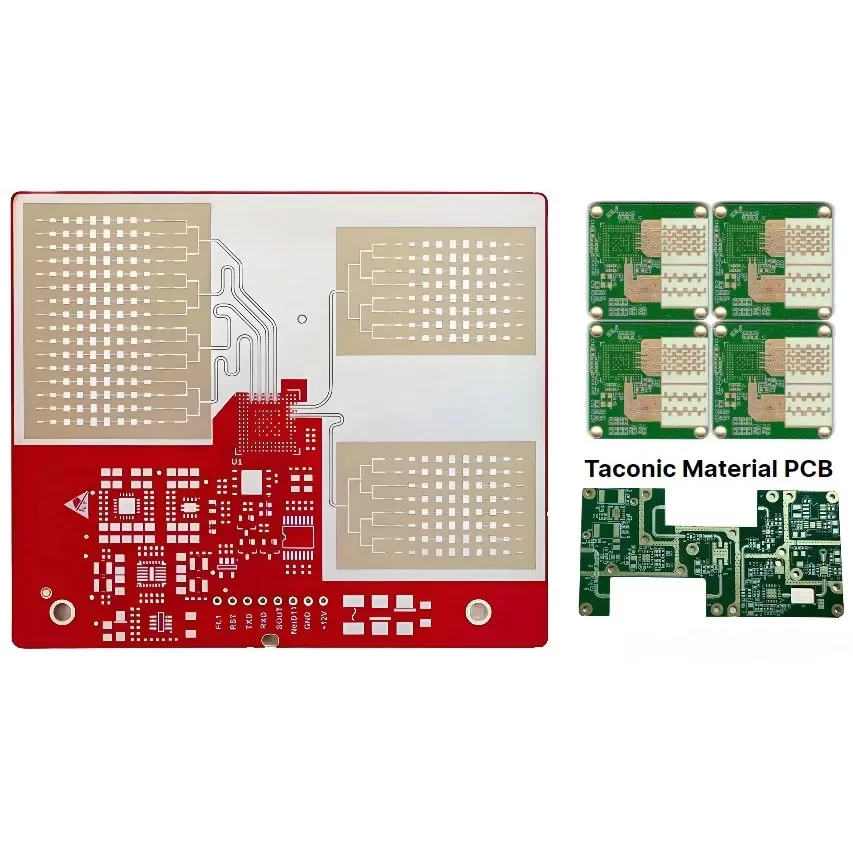

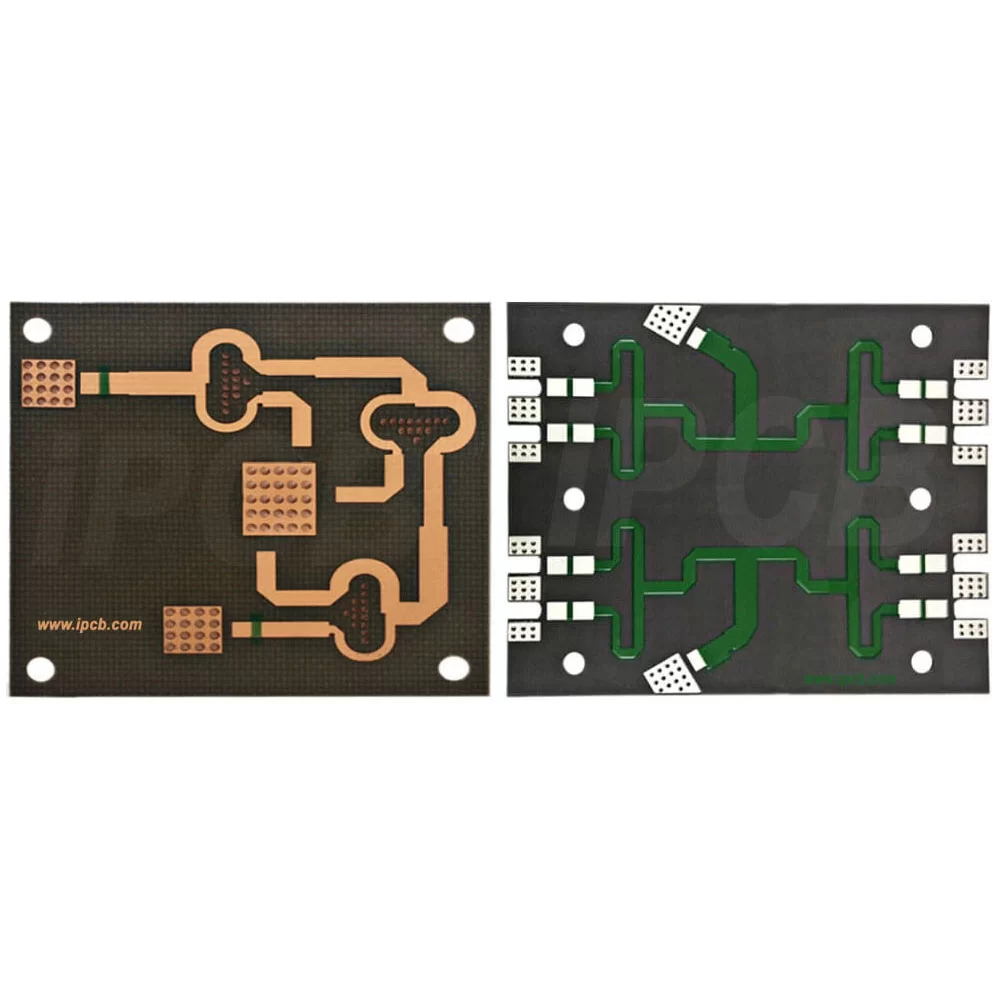

Taconic PCB is a printed circuit board specifically designed with the substrates produced by the company called Taconic Advanced Dielectric division. They specializes in high-performance laminates for RF or microwave and also for high-speed digital applications. These PCB materials are known for their exceptional electrical properties and reliability which make them suitable for applications where signal integrity and thermal management.

Taconic PCB includes PTFE and ceramic-filled PTFE. PTFE (Polytetrafluoroethylene) is a synthetic fluoropolymer and it has some excellent properties like high thermal resistance, less friction and remarkable electrical insulation.

Taconic PCB materials can be used in LNAs, NLBs, PCS/PCN antenna systems, Global Positioning System (GPS) and UMTS antenna systems, as well as power amplifiers, passive components, collision avoidance radar systems, airborne guidance and remote control technology, and phased array radar systems.

Applications

Telecommunication: Routers, switches and communication devices

Automotive: ECUs (Engine Control Units), infotainment systems, and ADAS (Advanced driver-assistance system) of the automotive industry.

- Medical Devices: MRI machines, CT scanners, implantable medical devices.

- Wireless communication

- Aerospace and defense

- High Frequency Applications

Advantages

High Performance: The design of Taconic plates is made for applications that need high performance. They have high thermal conductivity, stable electric properties and low dielectric loss which make them ideal for electronic systems that use Radio Frequency (RF).

Signal Integrity: Taconic PCBs have significant signal integrity and minimum signal loss. This is also applicable at high frequencies and crucial for applications where the certainty of signal transmission. Such as telecommunication, aerospace and defense.

Heat Management: In some Taconic materials, there is high thermal conductivity. This allows the dissipation of heat effectively from electronic components.

Dimension Stability: They exhibit good stability in dimension. They maintain excellent dimensions under varying temperatures and humid conditions.

If you have any camping barbeque equipment inquiry, please feel free to contact us.

Managing kitting and packaging in-house can be time-consuming, costly, and error-prone.

Maybe an off-the-shelf cable can't meet your needs.

Twisting entwines multiple wires and arranges them tightly next to each other. Depending on the AWG size, we can group up to fifty conductors.

Shielding refers to the metallic layer surrounding a cable’s conductor, created to limit signal interference between the wire and external fields.

PCB manufacturing is the process of building a physical PCB from a PCB design according to a certain set of specifications.

The following design standards refer to the IPC-SM-782A standard and the design of some famous Japanese design manufacturers and some better design solutions accumulated in the manufacturing experience.

Via holes, also known as through holes, play a role in connecting different parts of a circuit board.