1. Features: High reliability, strong resistance to vibration and impact, and the ability to adapt to the complex driving environment and harsh working conditions of automobiles, while meeting the high – precision and high – performance requirements of automotive electronics.

2. Applications: Used in automotive electronic control units (such as engine control, transmission control), in – vehicle entertainment systems, dashboards, advanced driver – assistance systems (ADAS), etc., and are important components for realizing the intelligence and informatization of automobiles.

3. Selling points:

Compliance with TS 16949.

Use of automotive – grade components.

4. Processes: AOI test, FT test, ICT test, BGA technic, selective wave soldering, SMT, DIP, wave soldering, reflow soldering.

5. Customization: customization according to customers' design files.

6. PCB standards for the Auto electronics

Automotive PCBs must adhere to stringent standards and specifications to ensure their reliability, stability, and safety within automotive electronic systems. Several common automotive PCB standards include:

IPC-A-600G: This industry standard for printed circuit boards covers requirements for PCB appearance, dimensions, layout, surface characteristics, and applies to various types of PCBs, including automotive PCBs.

IPC-6012: This standard provides detailed quality requirements for rigid PCBs and rigid-flex PCBs, encompassing aspects such as materials, manufacturing processes, and performance, applicable to automotive electronic PCBs.

ISO 26262: An international standard focused on automotive functional safety, spanning the entire safety lifecycle from safety concept to decommissioning. It imposes strict safety requirements on the design, manufacturing, and application of automotive PCBs.

AEC-Q100/AEC-Q200: Quality assessment standards for automotive electronic components, applicable to integrated circuits and buffer components. These standards cover temperature range, reliability testing, environmental robustness, among other aspects.

JESD22-A100: A standard for environmental stress testing of electronic components and modules, covering methods such as humidity, temperature, vibration tests, used to evaluate automotive PCB performance under diverse conditions.

IEC 61508: An international standard for functional safety, widely applicable to automotive electronic systems. It necessitates the consideration of safety aspects throughout the development and production stages of PCBs.

UL 94: This standard assesses the flammability of plastic materials to ensure materials used in automotive PCBs meet fire safety requirements.

RoHS (Restriction of Hazardous Substances Directive): In the context of automotive electronics, RoHS standards prohibit the use of specified hazardous substances in PCBs to protect the environment and user health.

-20251124061922.webp)

PCB type: Rigid PCB

Layer: Multi-layer

Base material: FR-4

Solder mask: Green

Silk screen: White

Surface treatment: HASL

-20251124060925.webp)

PCB type: Rigid PCB

Layer: Multi-layer

Base material: Aluminum base

Solder mask: White

Silk screen: Black

Surface treatment: Lead-free HASL

Application:PCBA with 8 high light LEDs for Car reading light

-20251124060422.webp)

PCB type: Rigid PCB

Layer: Multi-layer

Base material: Aluminum base

Solder mask: Black

Silk screen: No

Surface treatment: Lead-free HASL

Applications: 12 high-light LEDs for Car foot-hole light

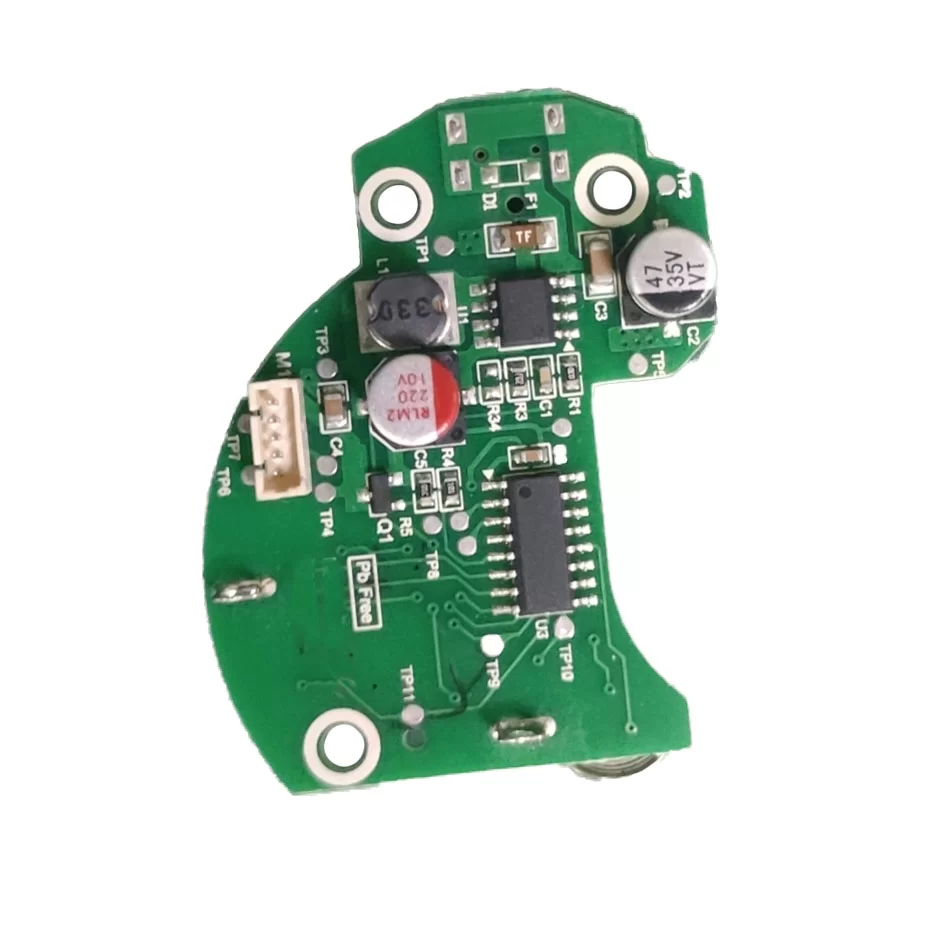

PCB type: rigid PCB

Layer: multi-layer

Base material: FR-4

Solder mask: Green

Silk screen: White

Surface treatment: Lead-free HASL

Applications: PCBA for Car digital display thermos cup & Cooling cup & car refrigerator control board

-20251124032908.webp)

PCB type: rigid PCB

Layer: multi-layer

Base material: FR-4

Solder mask: Green

Silk screen: White

Surface treatment: Lead-free HASL

Applications: PCBA For Car Charger Wth Type-C Connector Supports 15W Wireless Fast Charging

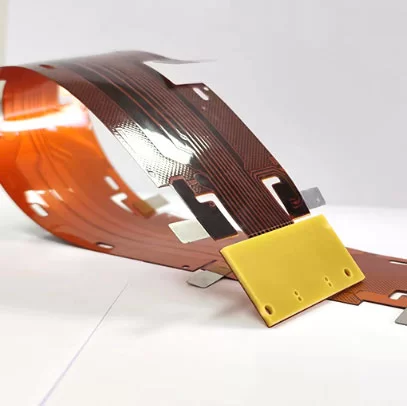

PCB type: rigid-flex PCB

Layer: multi-layer

Base material: FR-4, PI

Solder mask: yellow, yellow coverlay

Silk screen: White

Surface treatment: ENIG

Applications: Automotive lithium battery CCS integrated bus

PCB type: Rigid PCB

Layer: Multi-layer

Base material: FR-4

Solder mask: Green

Silk screen: White

Surface treatment: Lead-free HASL

-20251121093821.webp)

PCB type: Rigid PCB

Layer: Multi-layer

Base material: FR-4

Solder mask: Green

Silk screen: White

Surface treatment: Lead-free HASL

Applications: Automotive combination switch

-20251121093312.webp)

PCB type: Rigid PCB

Layer: Multi-layer

Base material: FR-4

Solder mask: Green

Silk screen: White

Surface treatment: Lead-free HASL

Applications: PCBA for Wired Automotive combination switch

PCB type: Rigid PCB

Layer: Multi-layer

Base material: Aluminum base

Solder mask: Black

Silk screen: No

Surface treatment: Lead-free HASL

Applications: Car Tail Light

Automation PCB assembly involves specific considerations and requirements due to the unique needs of the automation industry.

PCB type: Rigid PCB

Layer: Multi-layer

Base material: FR-4

Solder mask: Green

Silk screen: White

Surface treatment: Lead-free HASL

PCB type: Rigid PCB

Layer: Multi-layer

Base material: Aluminum

Solder mask: White

Silk screen: Black

Surface treatment: Lead-free HASL