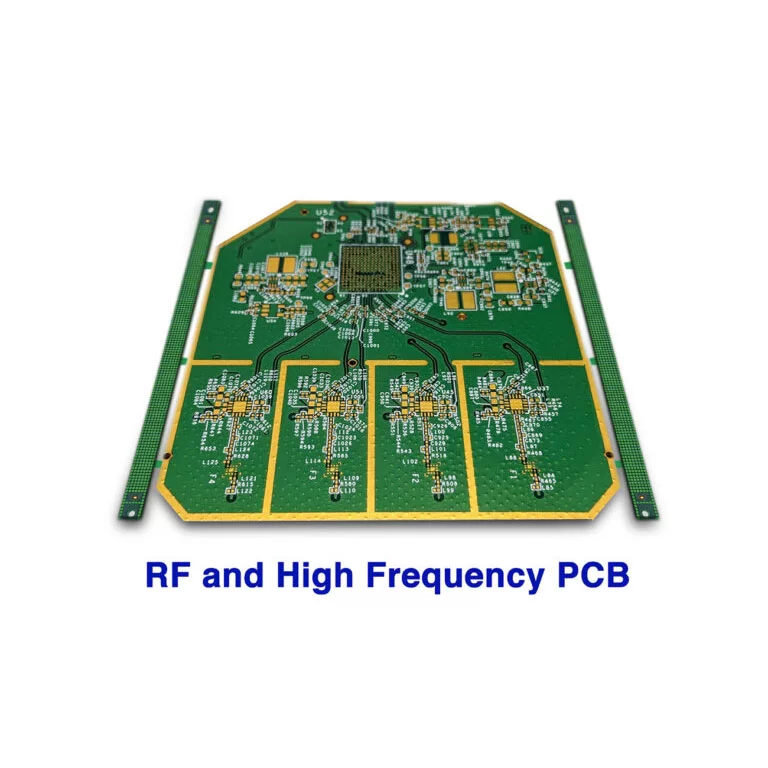

Electronic circuits behave very differently at high frequencies. This is mainly due to a change in the behavior of the passive components (resistors, inductors, and capacitors).

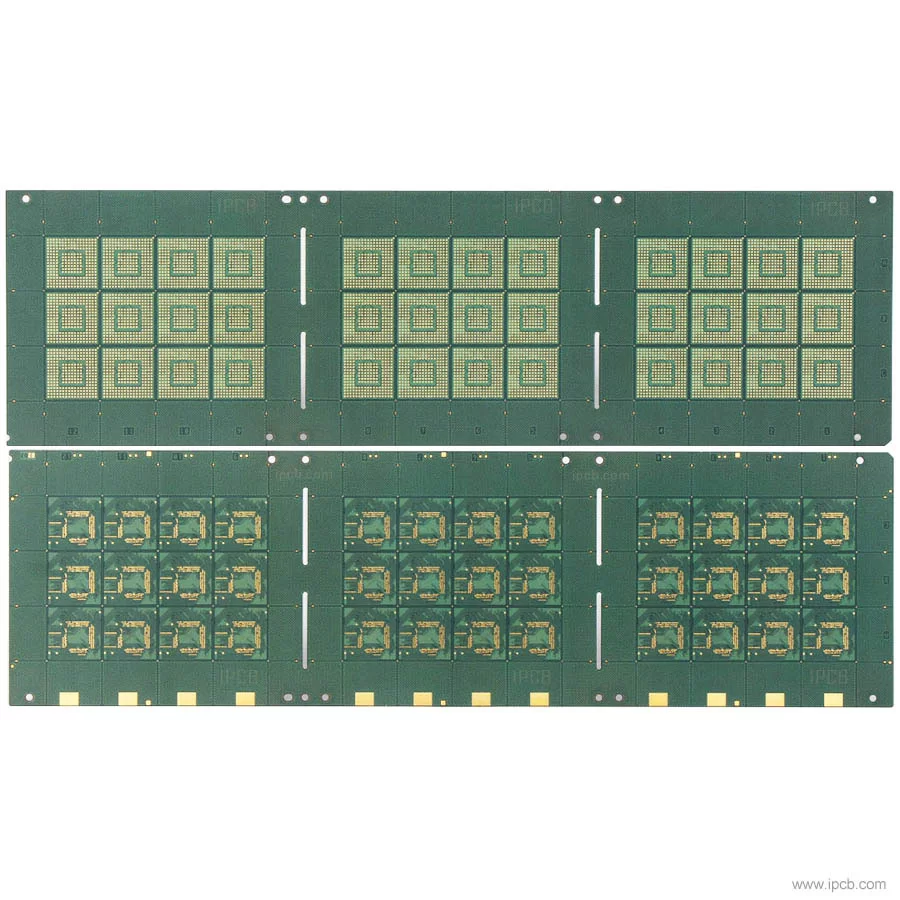

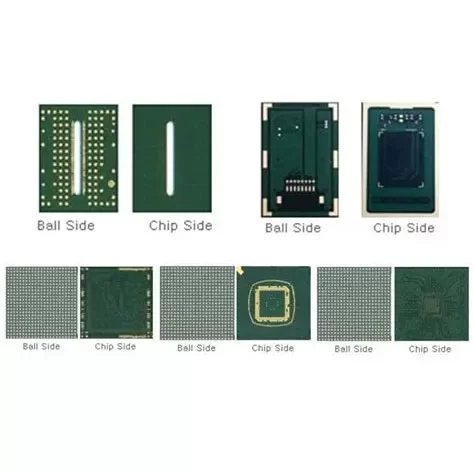

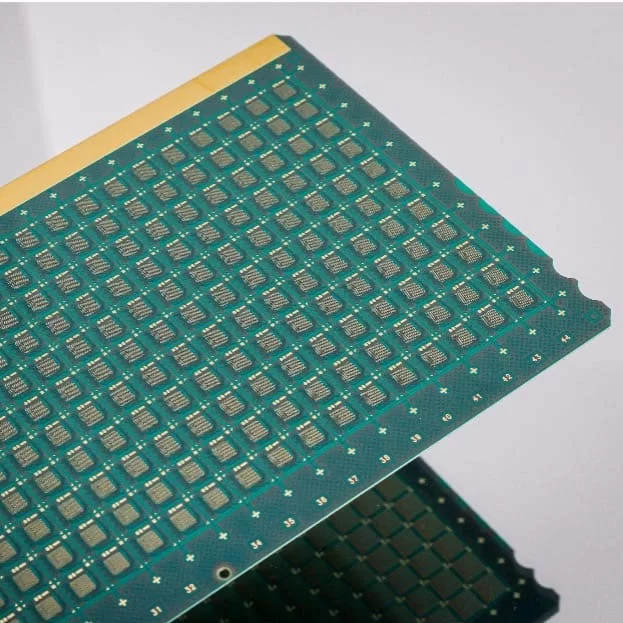

BGA stands for Ball Grid Array and they use solder balls arranged in the form of an array to make an electrical connection.

The IC substrate acts as a bridge that connects the microchip and PCB by making electrical connections.

IC substrate PCB is simply the base material of the IC package, providing connections between the PCB and the IC package on the printed circuit board.

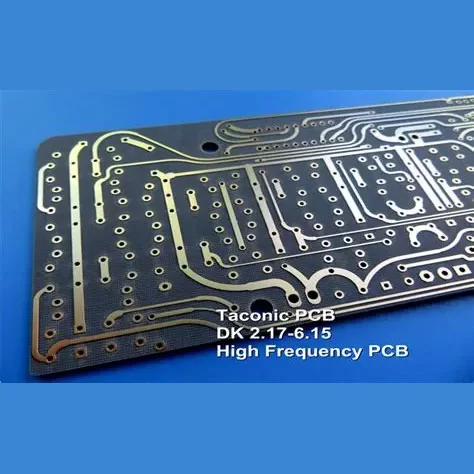

Taconic PCB is a printed circuit board specifically designed with the substrates produced by the company called Taconic Advanced Dielectric division.

Teflon circuit boards are circuit boards that employ PTFE as base material.

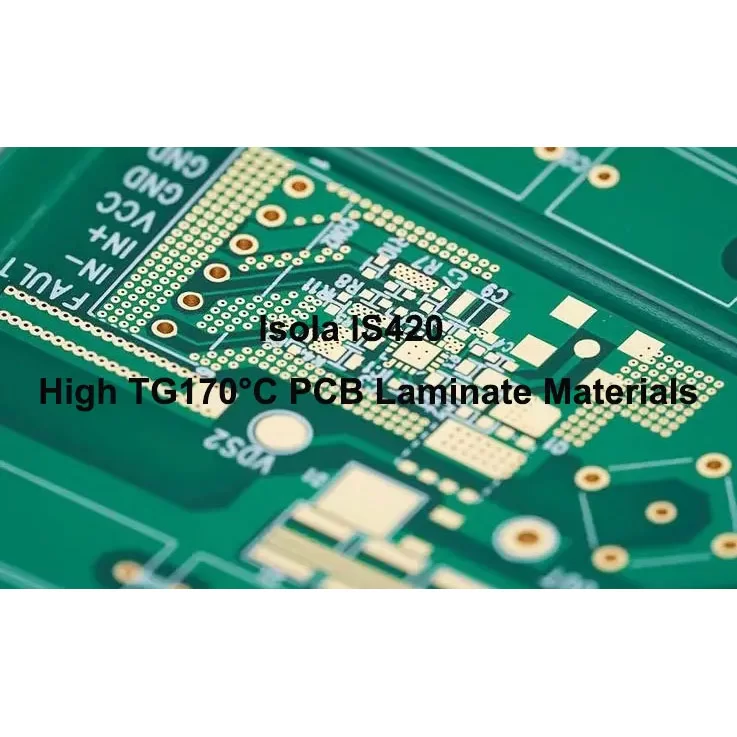

Isola is a company specializing in manufacturing and designing advanced material solutions for the electronics industry.

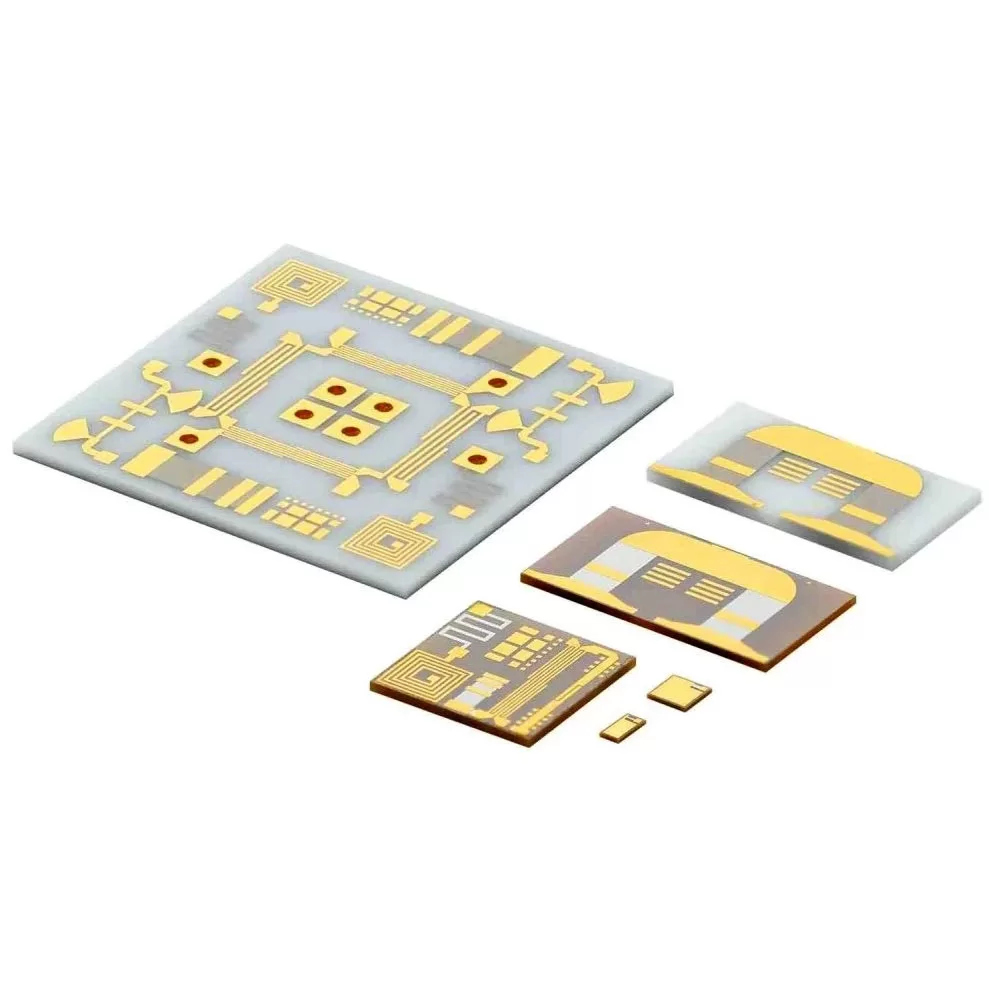

Silicon Nitride substrates have the best mix of electrical, thermal, and mechanical properties of any ceramic material.

Model:Aluminum nitride ceramic PCB

Material:Ceramic PCB,Ceramic Substrate

Layer:2Layer Ceramic PCB

Alumina ceramic PCB substrate is the most commonly used substrate material in electronic industry, because of its high strength and chemical stability compared with most other oxide ceramics in mechanical, thermal and electrical properties, and abundant raw materials, it is suitable for various technical manufacturing and different shapes.

Ceramic PCB substrate refers to a special process board with copper foil directly bonded to the surface (single or double sides) of alumina (Al2O3) or aluminum nitride (AlN) ceramic PCB substrate at high temperatures.

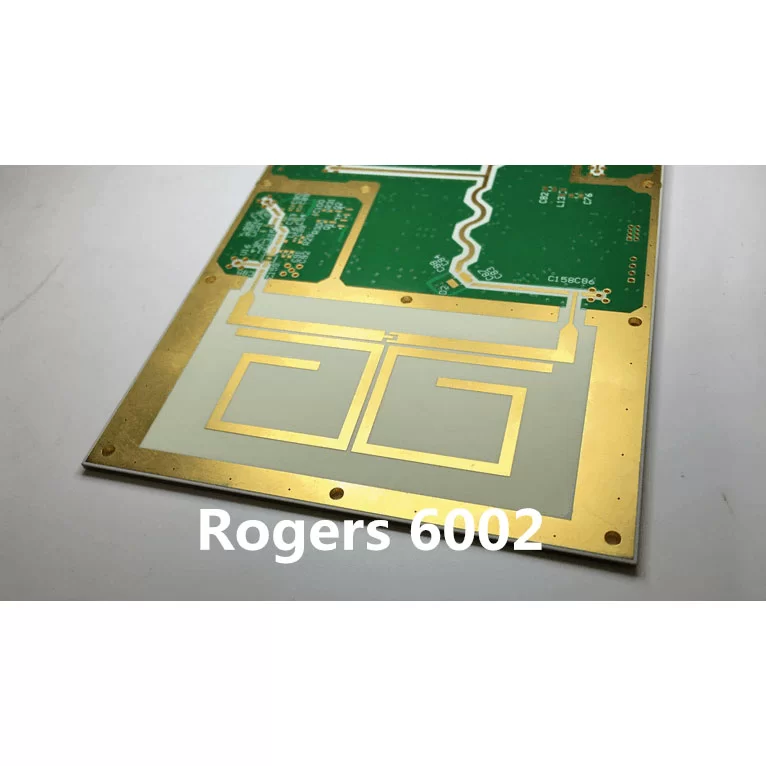

Low loss ensures excellent performance at high frequencies

RO3003 laminates offer exceptional dielectric constant (Dk) stability across temperature and frequency.